Open timing belt and preparation method

A technology of timing belt and belt body, applied in the field of open timing belt and preparation, can solve the problems of lack of market, poor bending resistance, poor high temperature resistance of polyurethane timing belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

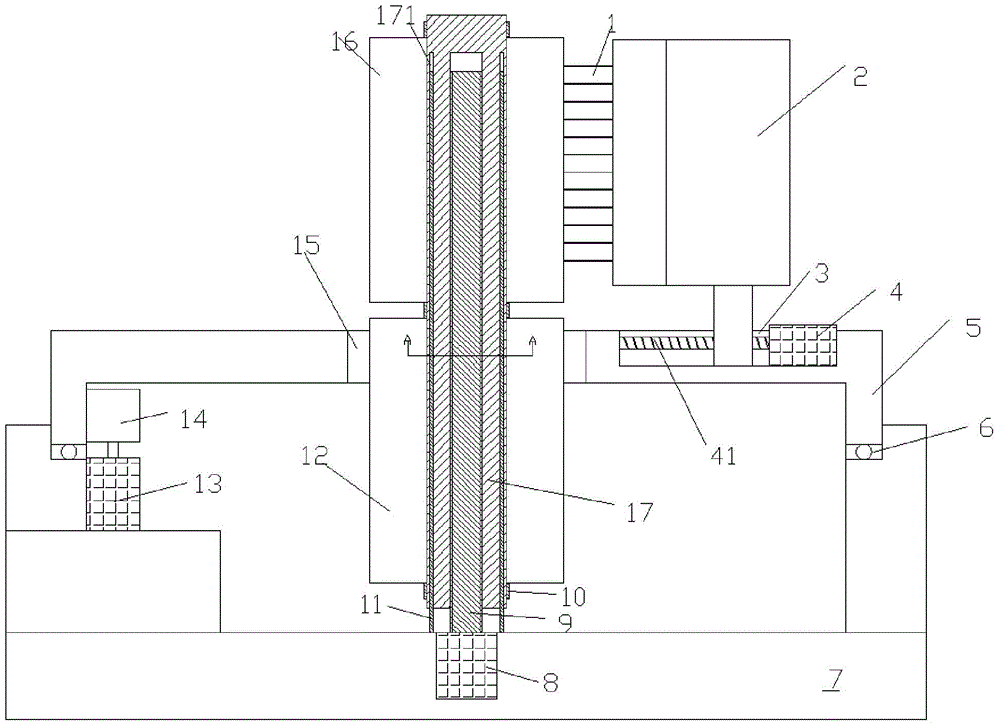

[0023] The best mode for carrying out the present invention will be described below with reference to the appropriate drawings.

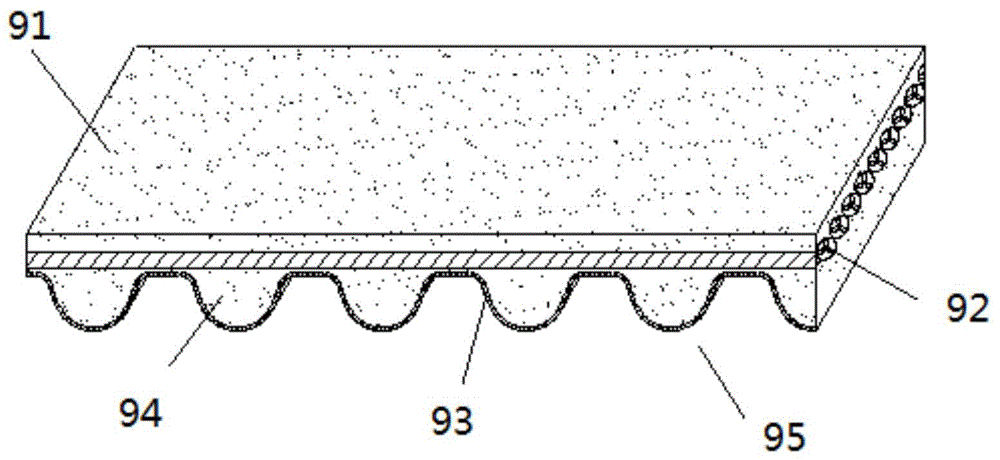

[0024] A method for preparing an open synchronous belt, wherein the structure of the linear belt body of the transmission flat belt is: a neoprene outer layer, a glass fiber layer, a neoprene toothed layer, and an elastic nylon cloth covering the toothed layer , the teeth on the neoprene belt tooth layer are arc-shaped teeth; the method includes the following steps:

[0025] Kneading the rubber mixture → beating the kneaded rubber material to the required concentration, so as to impregnate the elastic nylon cloth → cutting → molding the elastic nylon cloth, glass fiber and film on the molding mold , Obtain a shaped strip → vulcanize the shaped strip that is separated from the forming mold to obtain a vulcanized strip → cut the vulcanized strip to obtain an open timing belt with a required width.

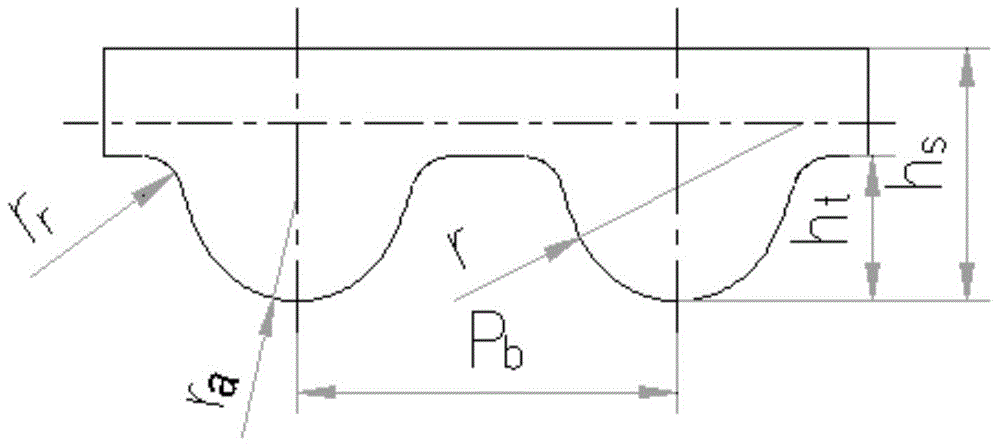

[0026] Wherein, the root transition radius rr of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com