A CO2 gas charging control device and a control method

A control device, CO2 technology, applied in the container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve the problems that the standard capacity of the gas cylinder cannot be filled, the dusty production workshop is not suitable for vibration, etc. , to achieve the effect of strong earthquake resistance, ensure weight accuracy, and ensure the safety of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

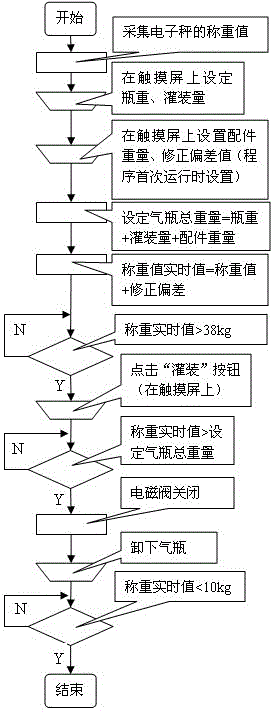

Examples

Embodiment 1

[0030] CO of Special Gas Operation Department of Beizhong Group 2 Take gas automatic filling equipment as an example.

[0031] 1. Preparation before work

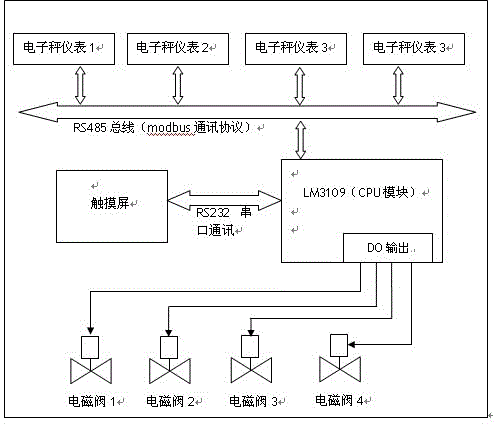

[0032] The present invention adopts special-purpose PLC, and CPU adopts LM3109 module. The controller has the logic operation function of the computer and its own load carrying capacity.

[0033] (1) Control hardware

[0034] One piece of LM3109 (PLC), one piece of HT7000 touch screen (10-inch screen), four electronic scales, four solenoid valves, eight intermediate relays, four buttons, four indicator lights, one communication cable, one control box, empty Open 1, CO 2 4 cylinders, CO 2 2 storage tanks and 1 electric piston pump.

[0035] LM3109 module is installed in the control box, intermediate relays, communication cables, and several signal lines, and HT7000 touch screen (10-inch screen), buttons, and indicator lights are installed on the control box panel.

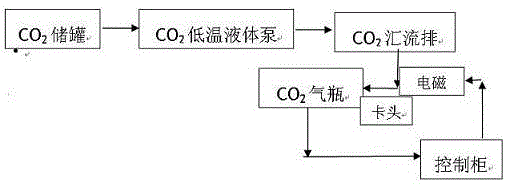

[0036] CO of the present invention 2 Gas storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com