Method for accurately setting optical axis of wedge lens

A lens and wedge-shaped technology, applied in the field of optical engineering, can solve the problems of inconvenient operation, limited axis-fixing accuracy of the lens, and inability to realize the axis-fixing of the wedge-shaped lens element, and achieve the effect of ensuring accuracy, high versatility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

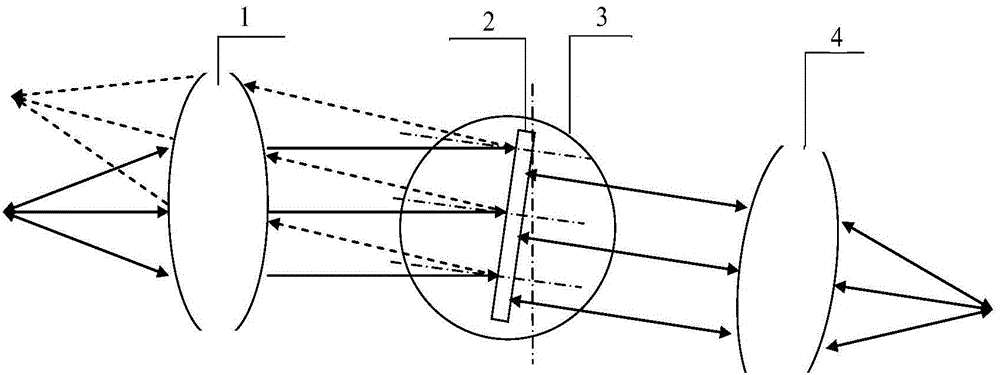

[0020] The specific embodiment and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

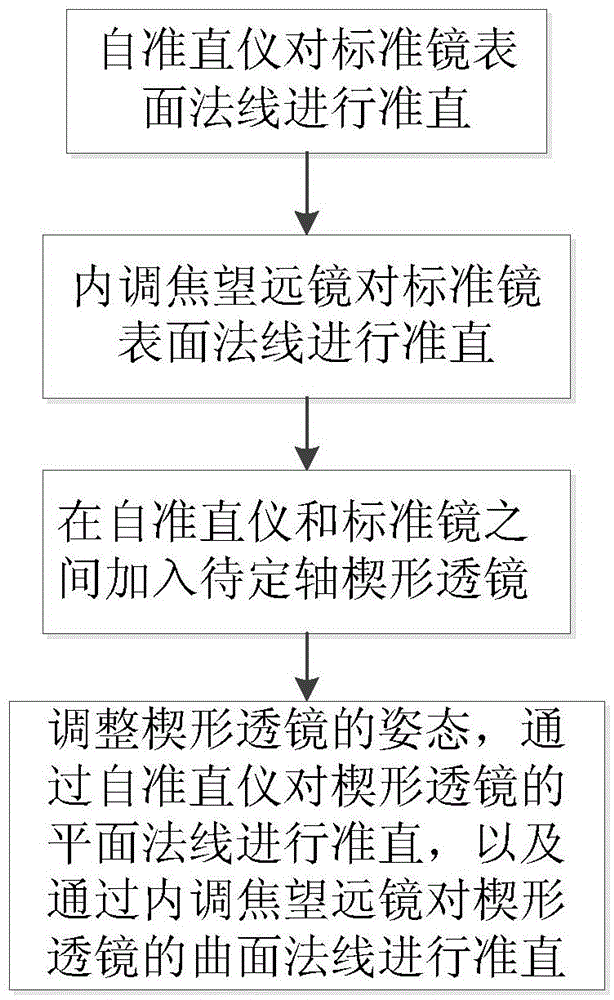

[0021] See attached figure 1 , a wedge-shaped lens precision axis fixed method, according to the following steps:

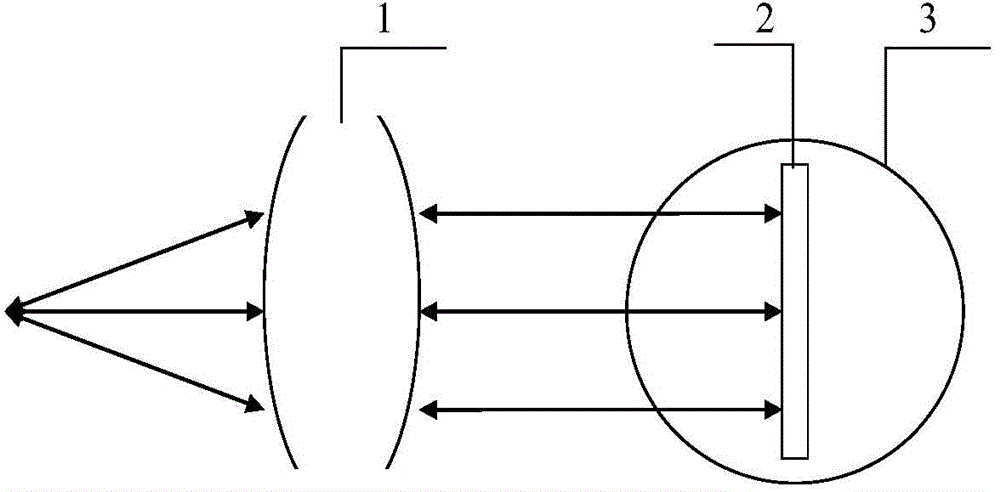

[0022] Step 1: Place a standard mirror 2 on the rotary indexing table 3, and set up an autocollimator 1 on one side of the standard mirror 2, such as figure 2 As shown, adjust the posture of the autocollimator 1 so that the crosshair image reflected by the standard mirror 2 to be tested coincides with the inherent self-collimation crosshair of the autocollimator 1, that is, the surface normal of the standard mirror 2 is collimated. straight;

[0023] In this embodiment, the autocollimator 1 adopts the Collapex AC300 digital display photoelectric autocollimator, which has the functions of automatic data collection and storage, and is easy to realize intelligent control. Its main performance inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com