External parameter calibration method used when camera and two-dimensional laser range finder are used in combined mode

A two-dimensional laser and calibration method technology, applied in the field of external parameter calibration, can solve the problems of large size of calibration plate, cumbersome measurement process, poor accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

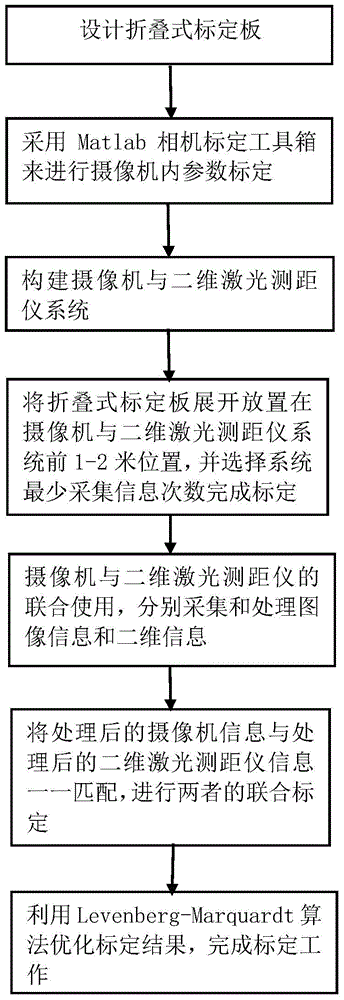

[0079] The first step is to design the folding calibration board:

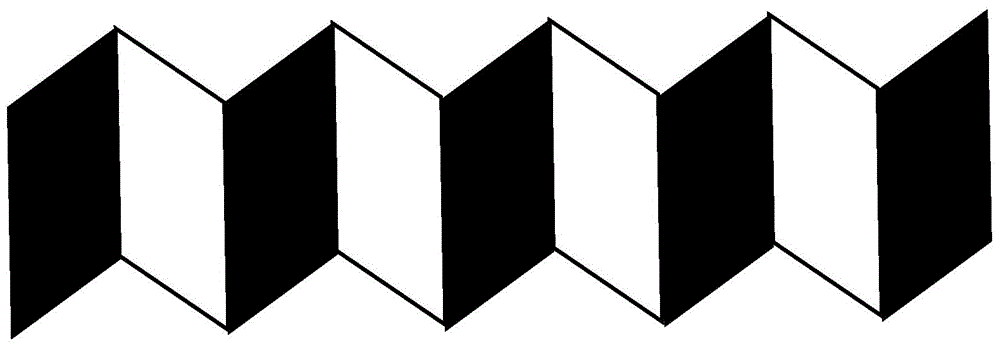

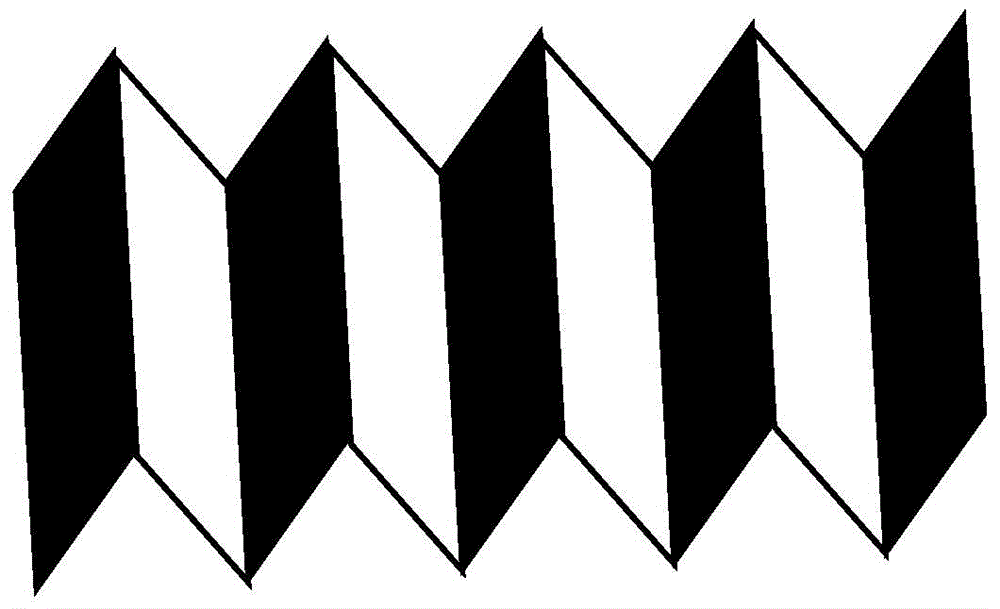

[0080] The calibration plate used in the external parameter calibration method when the camera and the two-dimensional laser rangefinder are used in combination is a folded calibration plate, which is a long plane formed by splicing five black and white small planes of rectangular plastic plates of 50cm×30cm , the long plane can be unfolded and folded, unfolded when in use, and the angle of unfolding can be adjusted freely;

[0081] The second step is to use the Matlab camera calibration toolbox to calibrate the internal parameters of the camera:

[0082] The camera uses a pinhole camera. Prepare a black and white checkerboard picture. The specification includes 13×10 black and white checkerboard squares. The size of each black and white checkerboard is 2cm×2cm. Use the camera to be calibrated from different angles Take 15 pictures, perform corner detection, and calculate the internal parameters of the camera...

Embodiment 2

[0119] Except for a long plane formed by splicing two rectangular black and white facets of 50cm×30cm alternately, and the foldable calibration plate has two black and white facets, which need to collect 8 times of information to complete the calibration, the others are the same as in embodiment 1.

Embodiment 3

[0121] Except for a long plane formed by splicing four rectangular black and white facets of 50cm×30cm alternately, and the folding calibration plate has four black and white facets, which require three times of information collection to complete the calibration, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com