Low-maintenance storage battery positive plate cleaning and alkalizing device and cleaning method

A battery and positive plate technology is applied in the field of low-maintenance battery positive plate cleaning and alkali addition devices, and can solve problems such as adverse effects on the activity of positive plate active substances, limited migration, and poor sulfuric acid cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

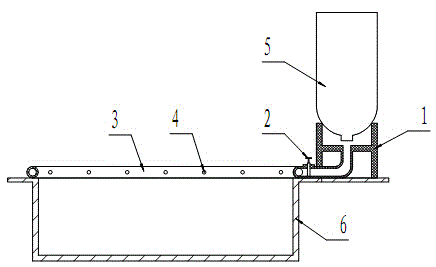

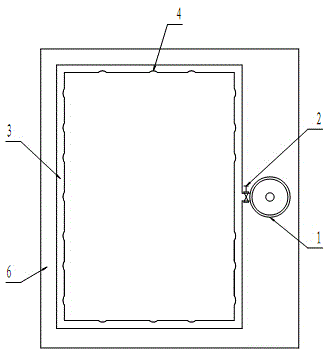

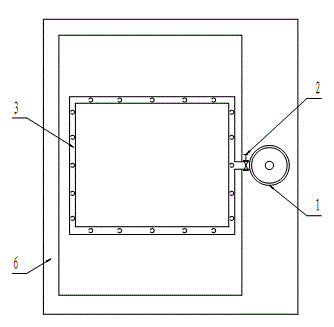

[0029] Referring to Fig. 1, the less-maintenance storage battery positive plate cleaning and adding alkali device described in the present invention is arranged on the top of the storage battery pole plate cleaning tank 6, and includes the lye containing barrel 5, the lye tank 1 and the lye delivery pipe 3; The lye containing barrel 5 is placed upside down above the lye tank 1; the lye tank 1 is arranged on the peripheral table top of the storage battery pole plate cleaning tank 6, and the bottom surface of the lye tank 1 is communicated with the lye delivery pipe 3; the lye A control valve 2 is arranged between the conveying pipe 3 and the lye tank 1 , and a group of leakage holes 4 are all arranged on the pipe wall of the lye conveying pipe 3 .

[0030] see figure 1 , figure 2 , the first embodiment of the less-maintenance battery positive plate cleaning and adding alkali device of the present invention is: the lye delivery pipe 3 has a circular cross-sectional structure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com