Mower capable of adjusting mowing height of green belt and manufacture method thereof

A technology for green belts and lawn mowers, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as inconvenient adjustment, inconvenient operation and use, and large mechanical vibration, so as to ensure operational efficiency and strong applicability , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

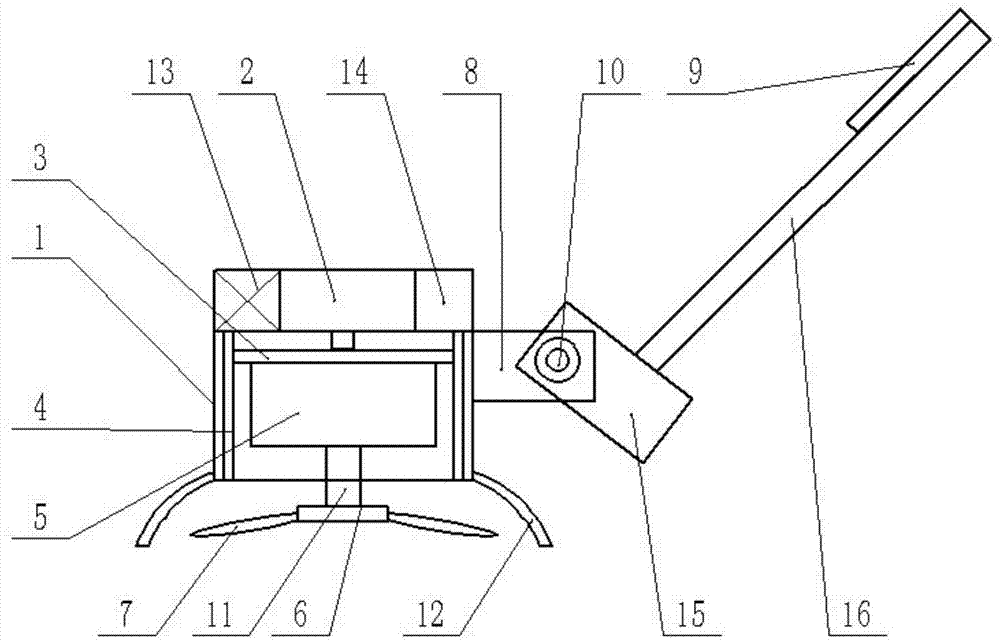

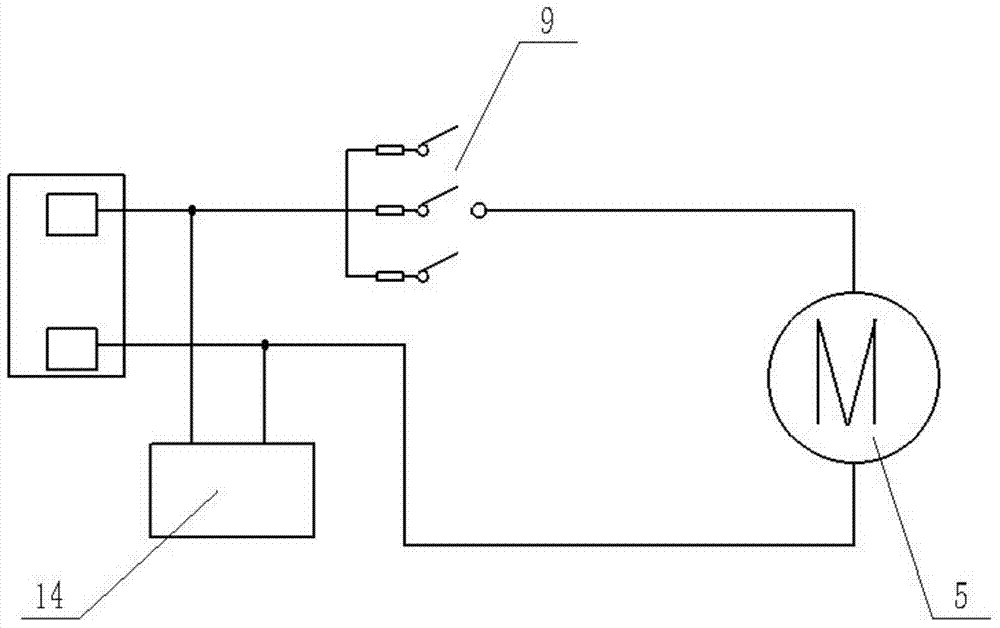

[0022] Example 1: see Figure 1-2 , a lawn mower with adjustable grass cutting height for green belts, including a casing 1, a cylinder 2, a motor 5, a blade 7, a control switch 9 and a protective cover 12, above the casing 1 are provided with a cylinder 2, a radiator 13 and The battery 14 has guide rails 4 fixed on both sides of the inside of the casing 1. The cylinder 2 is connected with a sliding plate 3 through a telescopic shaft. The sliding plate 3 is arranged inside the casing 1. The sliding plate 3 can be moved up and down through the guide rail 4, the bottom of the sliding plate 3 is provided with a motor 5, the rotating shaft 11 of the motor 5 is connected to a turntable 6 through the casing 1, and a blade 7 is arranged on the turntable 6; the present invention controls the sliding plate 3 through the cylinder 2. Therefore, the motor 5 is pushed up and down to control the height of the blade 7, so that the height of the mowing can be freely controlled according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com