Integrated composite spiral-wound membrane

A composite roll, roll membrane technology, applied in membrane, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of affecting the flow rate and volume of filtered water, unable to find a suitable force point, inconvenient replacement and maintenance, etc. The effect of large volume, increased quantity, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

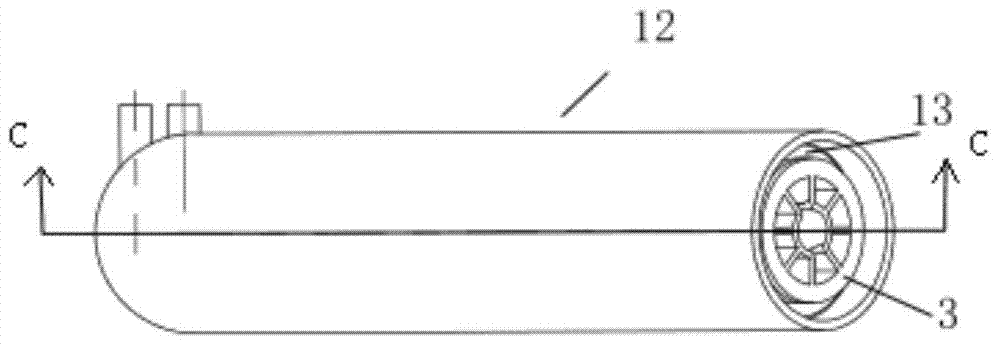

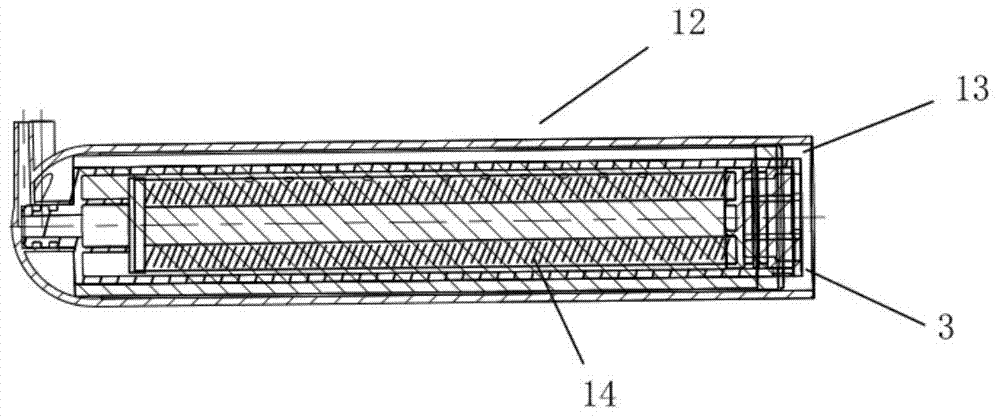

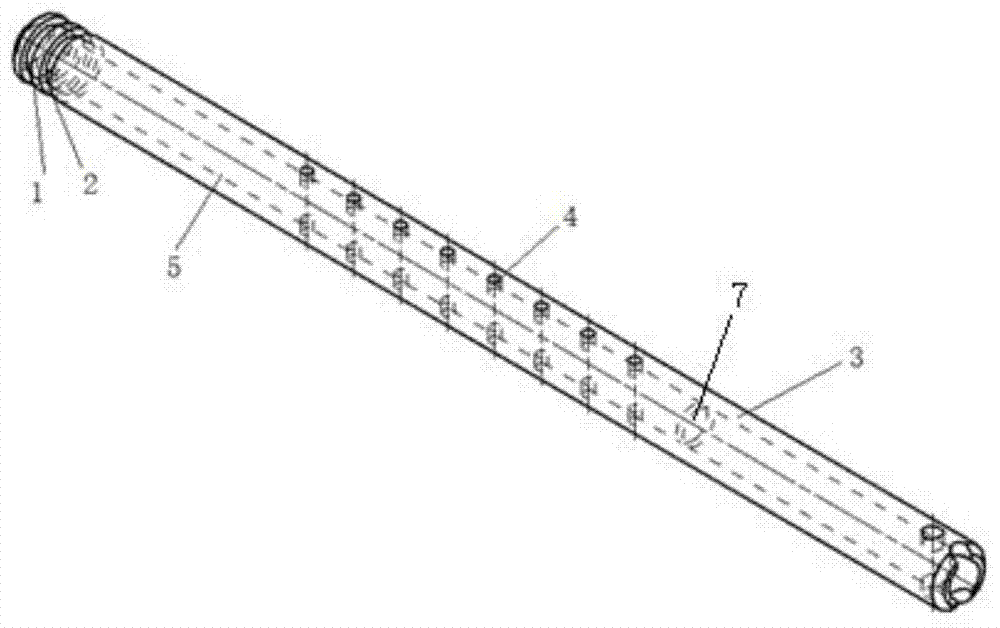

[0039] figure 1 , figure 2 As shown, the integrated composite roll-type membrane provided by the present invention is installed in a standard membrane housing 12 . It includes an RO reverse osmosis membrane 13 and a hollow central pipe 15 wound with the RO reverse osmosis membrane 13 . The central pipe 15 is provided with several water inlet holes 4 , and the water filtered by the RO reverse osmosis membrane 13 enters the pure water inlet chamber 10 of the central pipe 15 through the water inlet holes 4 .

[0040] The inner diameter of the center pipe 15 is set according to the diameter of the coiled membrane casing 12 , and an activated carbon filter element 14 is installed in the pure water inlet cavity 10 of the center pipe 12 .

[0041] The coiled membrane composed of a membrane and a hollow central tube woun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com