An automatic detection and sorting device and automatic sorting method for the inner and outer diameters of a wire drawing die

An automatic sorting and automatic detection technology, applied in sorting and other directions, can solve the problems of a large number of clamping wire drawing dies, complex detection process, labor-intensive and other problems, and achieve the effect of reducing retention time, improving sorting efficiency, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below through specific examples.

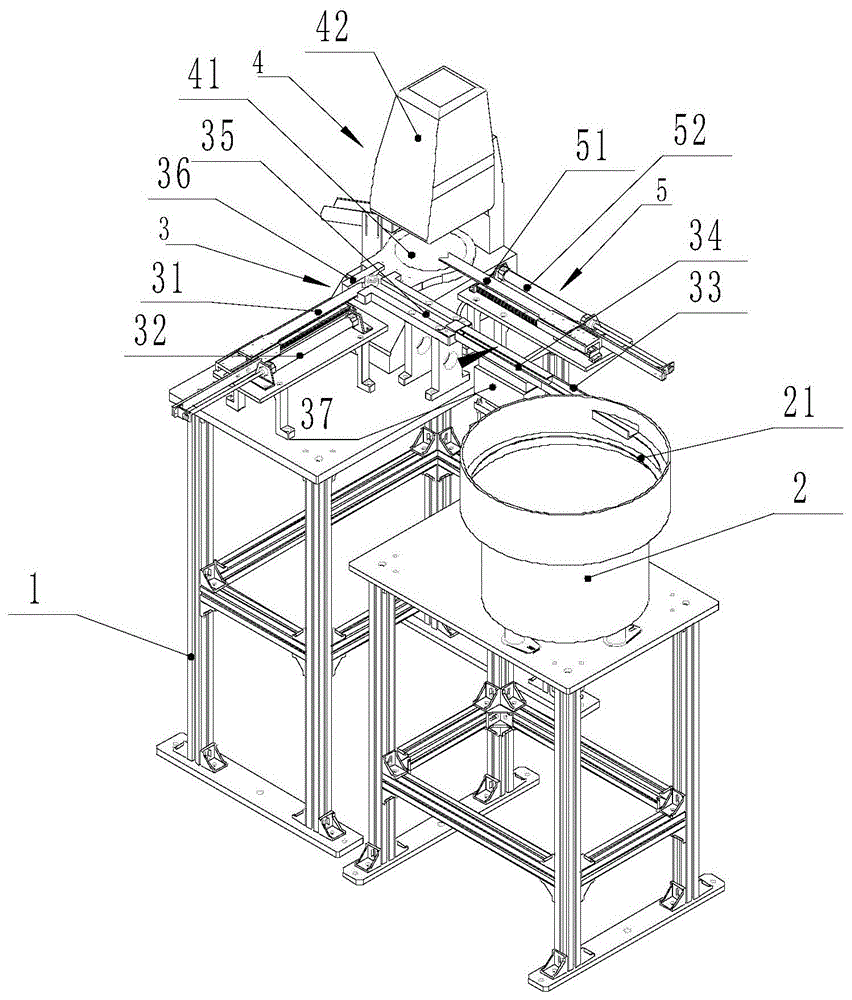

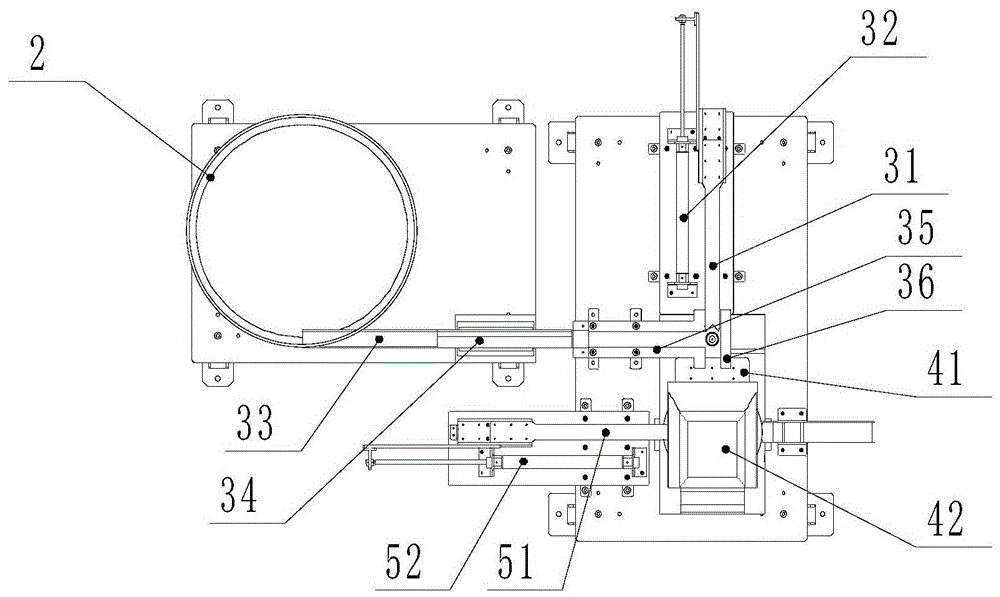

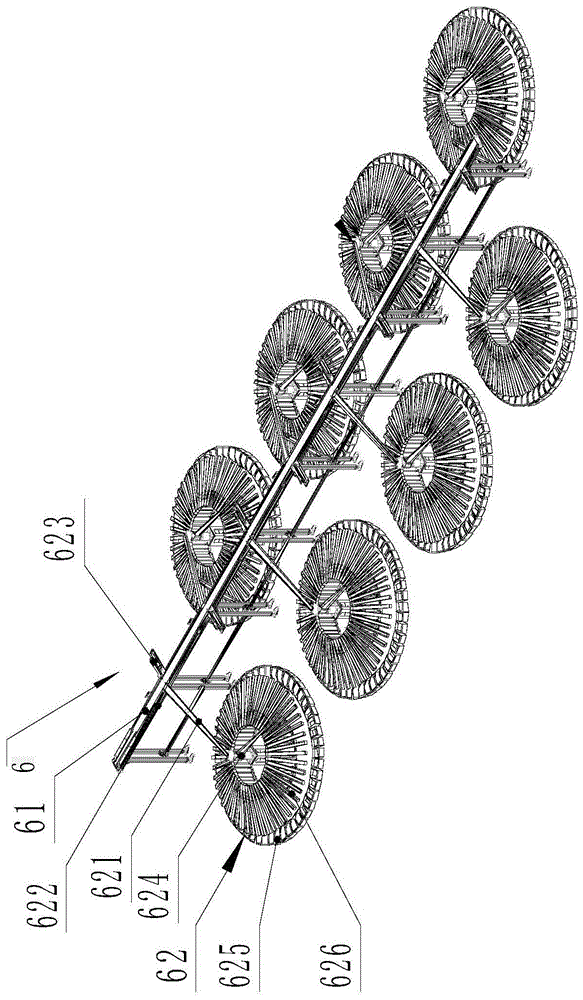

[0040] Such as Figure 1 to Figure 6 As shown, an automatic detection and sorting device for the inner and outer diameter of a wire drawing die, including a frame 1, a vibrating plate 2, an automatic feeding device 3, a detector 4, an automatic unloading device 5 and an automatic sorting device 6;

[0041] The vibrating plate 2 is installed on the frame 1, the vibrating plate 2 is provided with an arrangement groove 21, the width of the arrangement groove 21 is adapted to the diameter of the wire drawing die, and the arrangement groove 21 extends from the vibrating plate 2 to the The bottom spirals to the upper part of the vibrating plate 2; the vibrating plate 2 uses the principle of vibration to arrange the wire drawing dies on the arrangement groove 21 according to the specified arrangement. Generally, the inner holes of the wire drawing dies are arranged upwards, which does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com