Straight-line die

A mold and ruled technology, applied in the field of molds for electrical alloy electrode materials, can solve problems such as easy deformation, and achieve the effects of ensuring product quality, convenient and firm connection of molds, and light heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

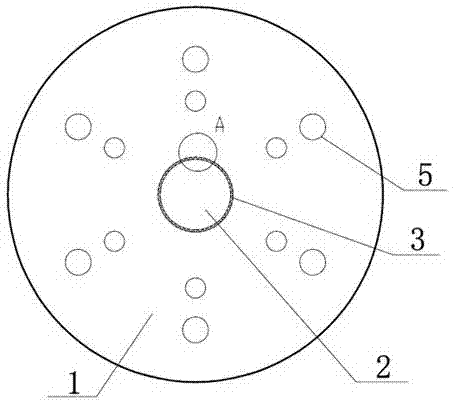

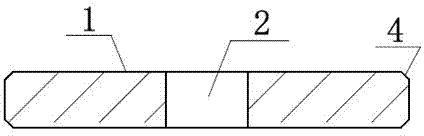

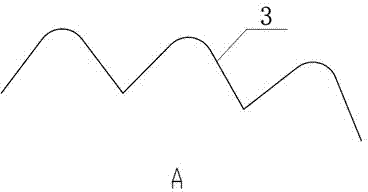

[0014] Such as Figure 1-3 As shown, the present invention relates to a straight grain mold, comprising a mold disk body 1, a connection hole 2 is arranged in the center of the mold disk body 1, and tooth patterns 3 are uniformly arranged on the inner hole wall surface of the connection hole 2, so that The upper and lower edges of the mold disc body 1 are provided with chamfers 4;

[0015] It should be noted that the surface of the mold disc body 1 is provided with several circular through holes 5 on a uniform circumference, and the circular through holes 5 are provided with two circles, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com