Alloy molten steel constant-pressure injection device and constant-pressure injection method

A spray device, alloy steel technology, applied in metal processing equipment, casting melt containers, manufacturing tools, etc., can solve the problems of inconsistent size, inability to ensure constant nozzle pressure, and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

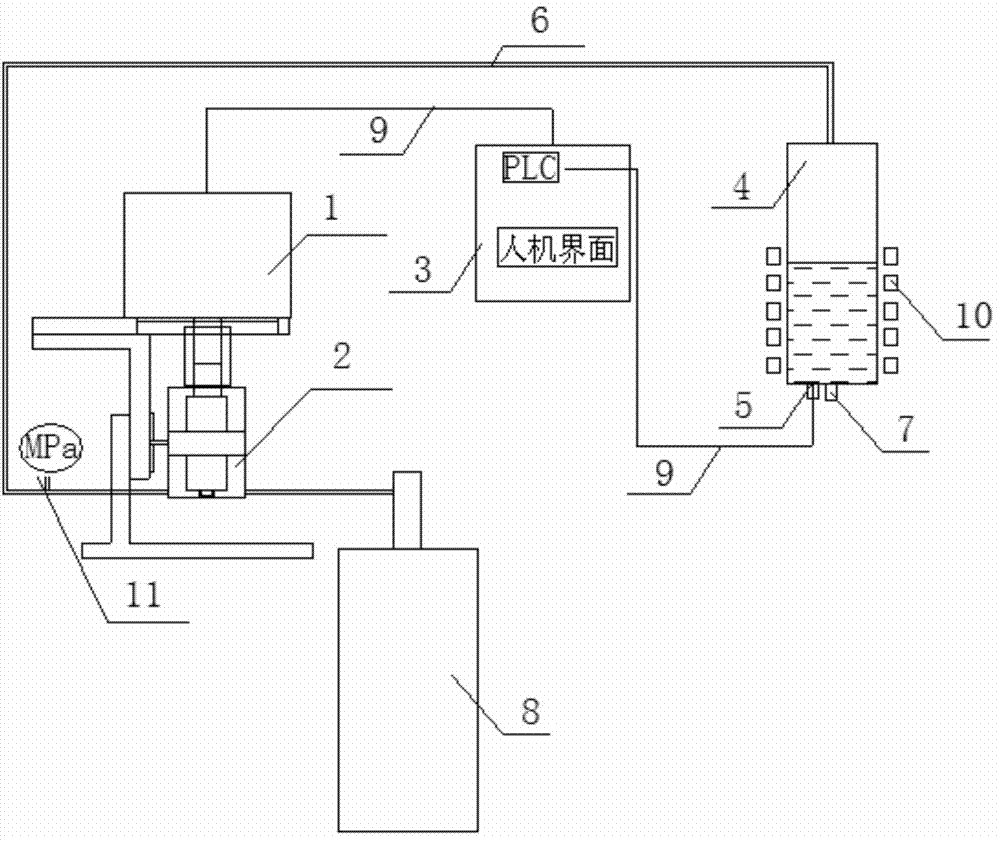

[0029] Such as figure 1 As shown, the present invention provides a constant pressure spraying device for molten alloy steel, which includes an adjusting actuator 1, a precision pressure regulating valve 2, a microcomputer control system 3, a steel ladle 4, a pressure sensor 5, an air pipe 6, and a nozzle Port 7, gas source 8, signal line 9 and pressure gauge 11; it is characterized in that: a pressure sensor 5 is installed at the nozzle port 7 at the bottom of the ladle 4, and the pressure sensor 5 is connected to the microcomputer in turn through the signal line 9 The control system 3 and the regulating actuator 1; the upper part of the ladle 4 is sealed and connected to the air delivery pipe 6, and the air delivery pipe 6 is airtightly connected to the air source 8 through the pressure gauge 11 and the precision pressure regulating valve 2; the precision pressure regulation The valve 2 is connected to the regulating actuator 1; the ladle 4 is set in the medium frequency indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com