Lamp holder wire supporting fixture for automatic LED (light emitting diode) lamp production line

A technology for LED lamps and production lines, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of low automation production efficiency and difficulty in power line aligning, and achieve high production efficiency, small mechanical impact, and high synchronization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

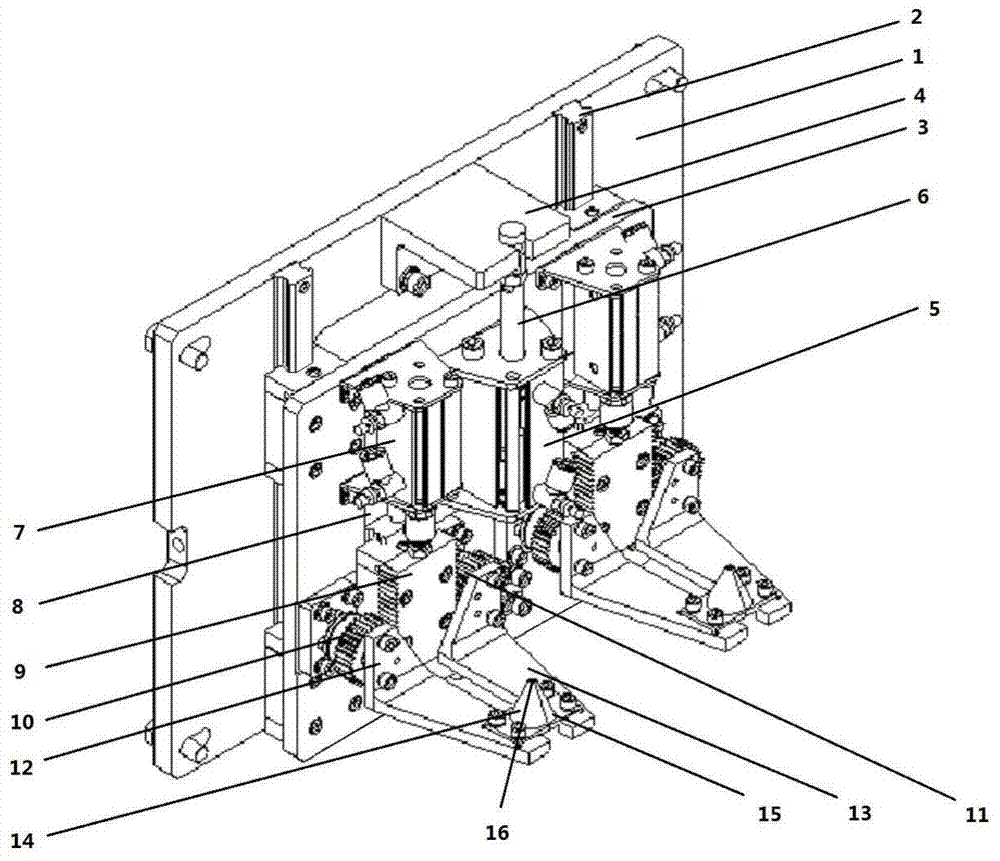

[0026] Such as figure 1 As shown, the automatic LED lighting production line of the present invention uses a lamp head wire support fixture, which consists of a mounting plate 1, a linear guide rail 2, a sliding plate 3, a sliding plate driving part, a taper sleeve rotation drive assembly, a left taper sleeve connecting plate 12, and a right taper sleeve. The connecting plate 13, the left-handed half-cone 14 and the right-handed half-cone 15 are composed; the sliding plate driving part is composed of a fixed ear plate 4 and a sliding cylinder 5, and the taper sleeve rotation driving assembly includes a left rotating gear 10, a right rotating gear 11 and Wheel drive components.

[0027] The mounting plate 1 is provided with a linear guide rail 2, and the sliding plate 3 is installed on the linear guide rail 2. The driving part of the sliding plate is composed of a fixed ear plate 4 and a sliding cylinder 5. The sliding cylinder 5 is fixed on the sliding plate 3, and the fixed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com