Injection blowing mold

A blow mold and injection mold technology, applied in the field of injection blow molds, can solve the problems of unsuitable transfer of multiple injection embryos at one time, inability to mass-produce, low production efficiency, etc., so as to shorten processing and molding time and improve production. Efficient, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

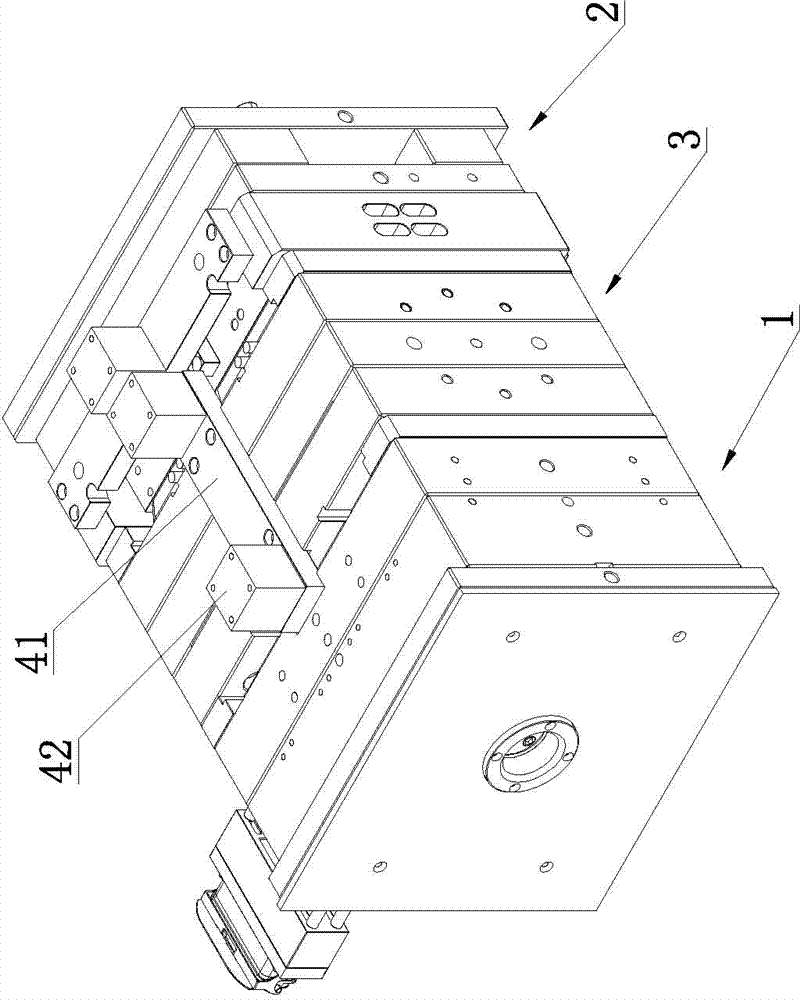

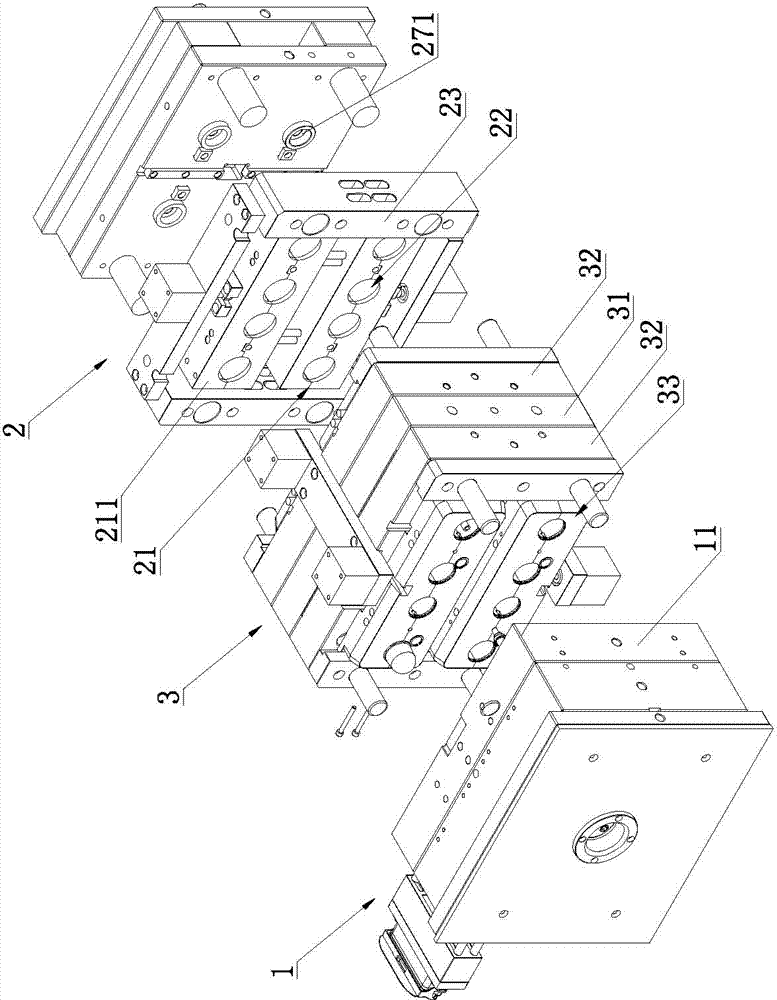

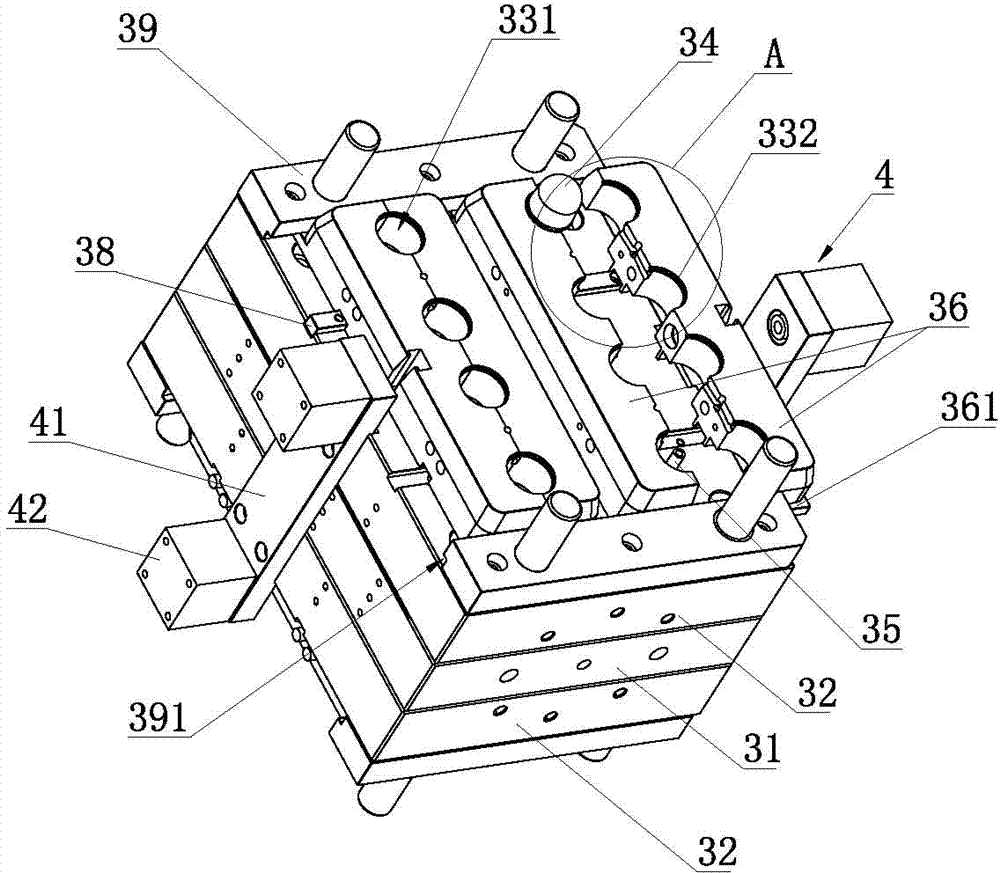

[0025] like Figure 1 to Figure 8 As shown, an injection blow mold includes an injection mold assembly 1 and a blow mold assembly 2, and also includes a turret device 3 arranged between the injection mold assembly 1 and the blow mold assembly 2, the turret device 3 Including a base plate 31, two tooth plate mounting plates 32 respectively arranged on both sides of the base plate 31, at least one tooth plate 33 arranged on the tooth plate mounting plate 32, a core 34 for forming injection molding and a Ventilated hollow blowing core 35, the tooth plate 33 is provided with at least one core hole 331 and an alveolar 332 arranged on the wall of the core hole 331, the core 34 is penetrated in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com