A plastic packaging material discharge device

A discharge device and molding compound technology, applied in the field of molding compound processing, can solve the problems of uneven blanking of plastic sealing compound, waste of raw materials, increase of production cost, etc., to avoid accumulation, avoid plastic empty material falling, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

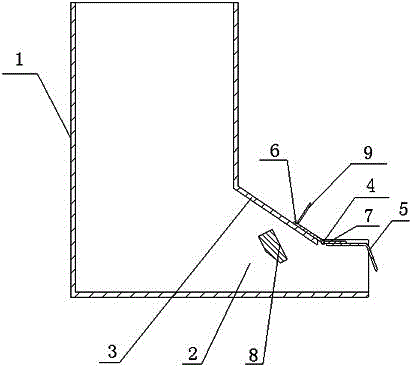

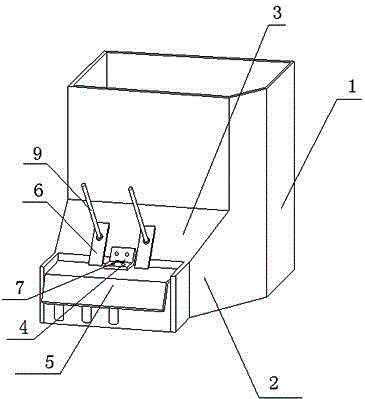

[0014] Such as figure 1 and figure 2 As shown, a plastic sealing compound discharging device includes a plastic sealing material box 1. The lower side wall of the plastic sealing material box 1 protrudes outward to form an outlet part 2. The front end of the outlet part 2 is open at the top. The top of the end is an inclined cover 3, and the outlet part 2 is connected with a baffle plate 5 through a hinge 4. The baffle plate 5 is provided with two positioning support plates 6, and the hinge 4 is located on the two positioning support plates. 6, the hinge 4 is covered with a torsion spring 7, one leg of the torsion spring 7 is located on the material stopper 5, the other leg of the torsion spring 7 is located on the cover 3, and the hinge 4 is on the torsion spring 7 It can be closed automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com