Plastic pipe inkjet printer

A technology of inkjet printers and plastic tubes, applied in typewriters, printing devices, printing, etc., can solve problems such as affecting the appearance and spraying position deviation, and achieve the effects of prolonging the working cycle, achieving support, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

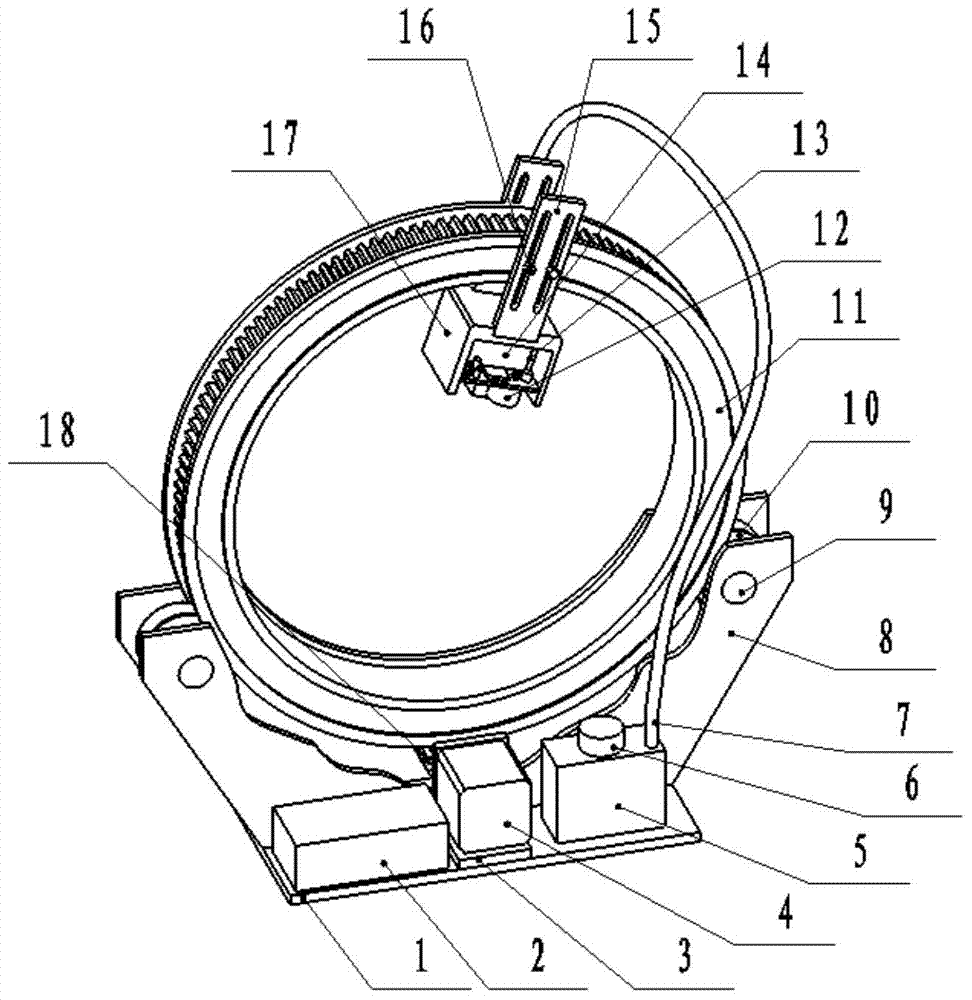

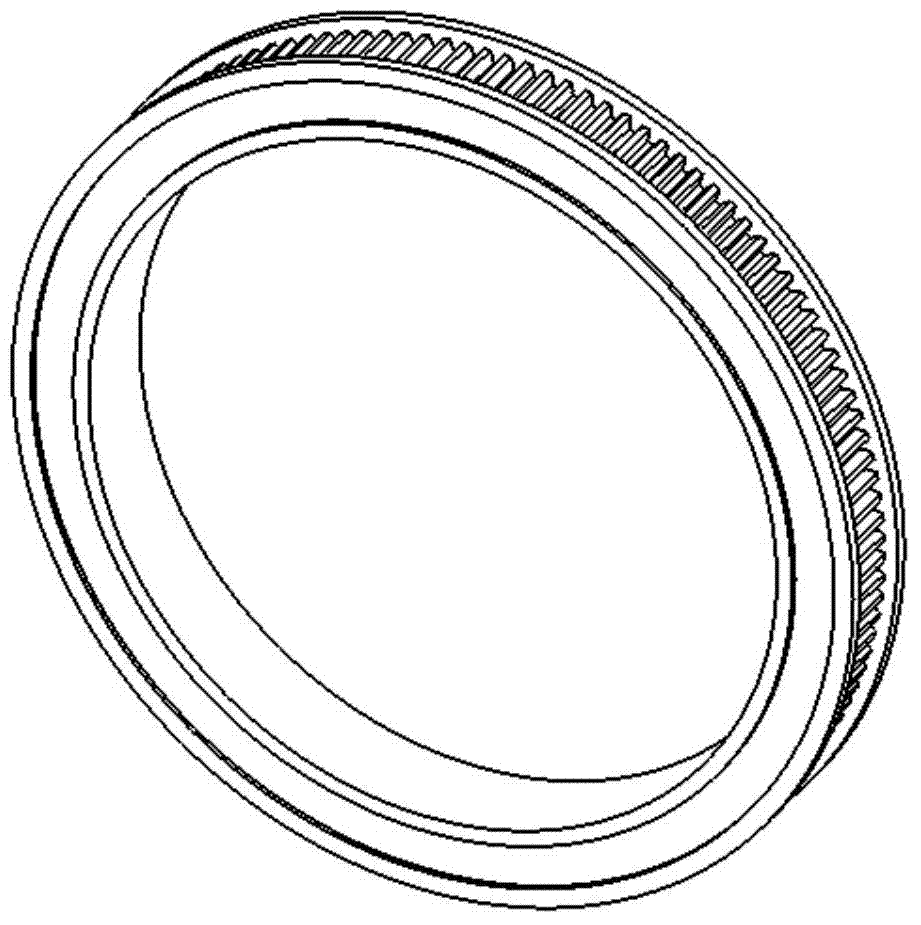

[0011] A plastic tube inkjet printer consists of a base plate 1, a controller 2, a motor bracket 3, a stepping motor 4, an ink tank 5, a micropump 6, an ink delivery tube 7, a vertical plate 8, a shaft 9, a bearing 10, and a turntable 11. CCD12, ink cartridge circuit board 13, ink cartridge 14, adjustment plate 15, adjustment screw 16, ink cartridge bracket 17, pinion 18, is characterized in that: bottom plate 1 is at the bottom of the entire device, vertical plate 8, motor bracket 3, The controller 2 and the ink barrel 5 are installed on the base plate 1, the stepping motor 4 is installed on the motor support 3, the pinion 18 is installed on the shaft of the stepping motor 4, and the center of the outer edge of the rotating disk 11 has a tooth arc. The tooth arc has the same modulus as the pinion 18, and is meshed for transmission. The shaft 9 is installed on a bracket composed of two vertical plates 8, and a bearing 10 is installed on the shaft 9. The outer surface of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com