Electric bypass valve device

A bypass valve, electric technology, applied in transportation and packaging, power steering mechanism, steering mechanism, etc., can solve the problems of inability to adapt to multi-level changes in steering assistance, high precision requirements for electromagnetic proportional valves, and single output assistance characteristic curve. , to improve the control stability and safety, solve the problem of fluttering, and enhance the feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

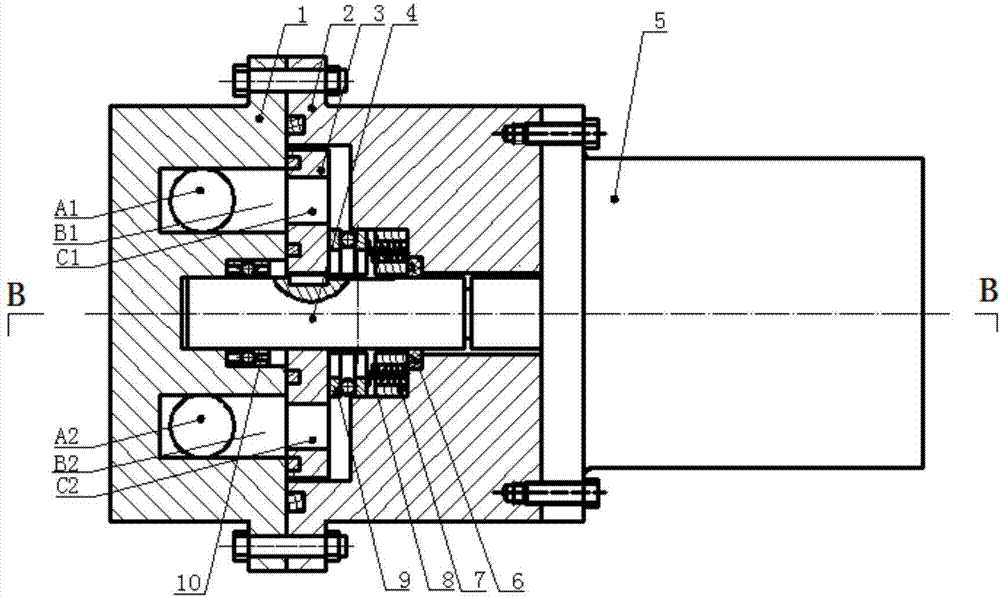

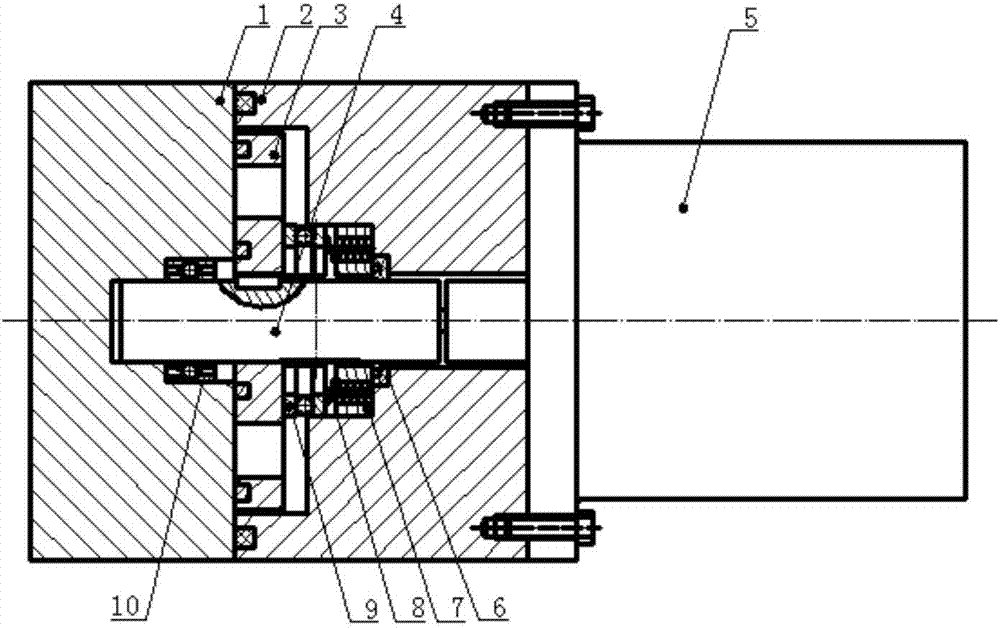

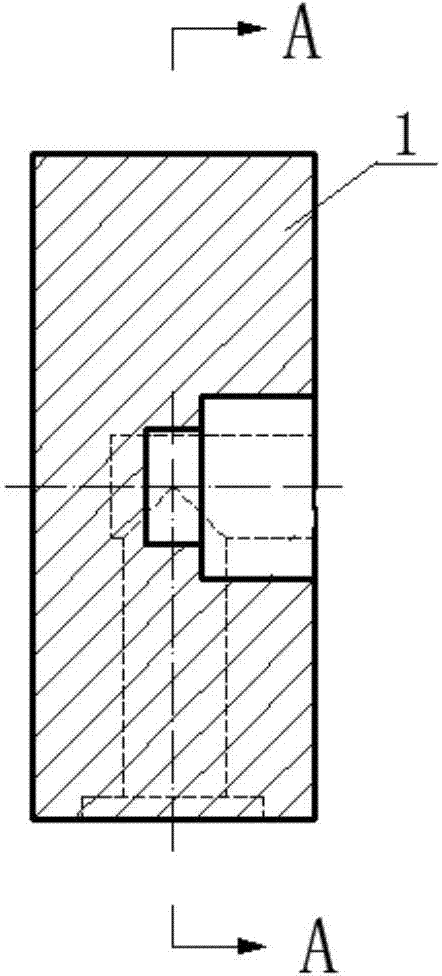

[0027] Such as figure 1 , 2 As shown, the electric bypass valve device of the present invention includes a first valve body 1, a second valve body 2, a rotating shaft 4 and a stepping motor 5; the rotating shaft 4 is connected to the output end of the stepping motor 5, and the The second valve body 2 and the first valve body 1 are sequentially installed on the rotating shaft 4 , and a bearing 10 is arranged between the first valve body 1 and the rotating shaft 4 . Both ends of the second valve body 2 are respectively connected to the first valve body 1 and the stepping motor 5 through bolts. The end surface of the second valve body 2 in contact with the first valve body 1 is provided with a ring groove for placing a sealing ring to prevent oil leakage.

[0028] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com