Transfer case

A turnover box and box body technology, applied in the direction of internal accessories, etc., can solve the problem that parts are easy to be hung up or scratched, and achieve the effect of being easy to be hung up or scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

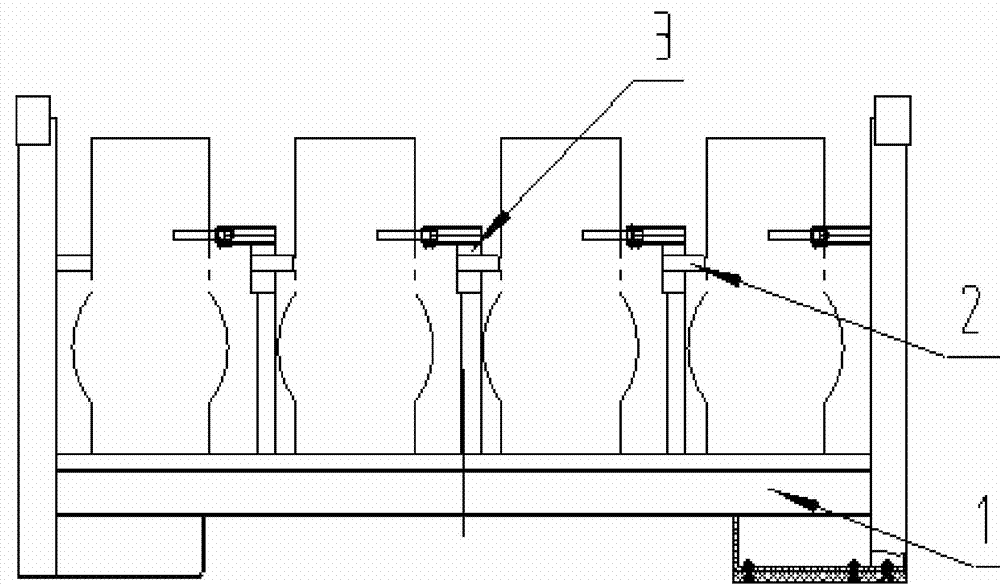

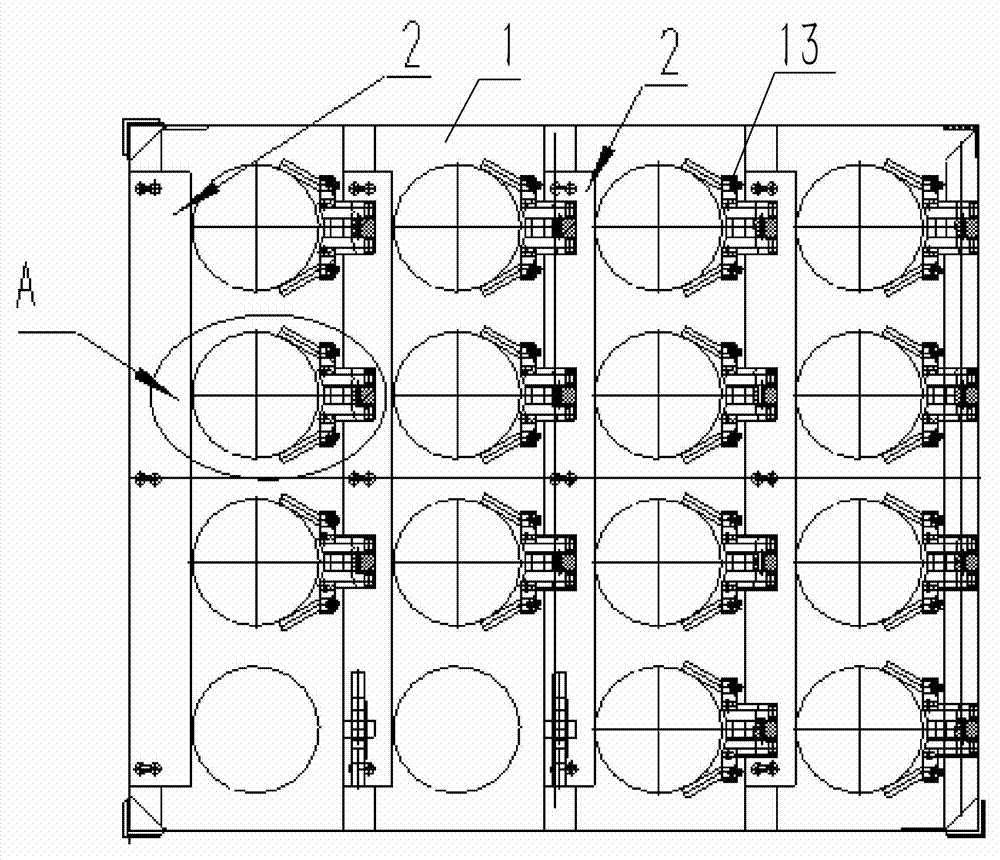

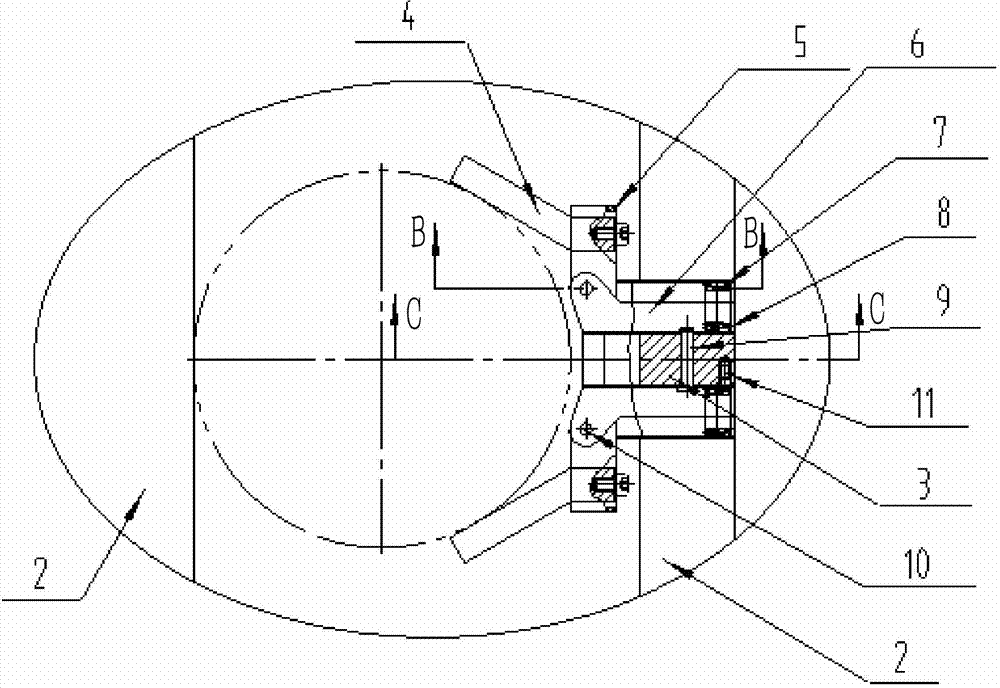

[0034] The embodiment of turnover box among the present invention: as Figure 1 to Figure 15 As shown, the turnover box is a turnover box with an anti-dumping mechanism, which is mainly composed of a box body, a mechanical claw 12 and a baffle plate 2. The box body includes a frame 1 at the bottom and plate-shaped or shelf-shaped spacers fixed thereon and arranged at intervals from left to right. The edge of the frame 1 is fixed with a surrounding plate that surrounds the periphery of each spacer. The plate is higher than the spacer, and the top of the spacer is provided with support blocks 3 uniformly spaced from front to back and a baffle 2 snap-connected to the support block 3, and the left edge of the baffle 2 is provided with four The support block 3 matches the installation slot of the buckle, the right edge of the baffle plate 2 protrudes from the right side of the spacer, and the support block 3 protrudes from the upper side of the baffle plate 2 . The mechanical claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com