RFID (radio frequency identification)-based two-bin rail-bound conveying vehicle and rail layout and positioning control method

A technology of RFID tags and conveying vehicles, applied in the field of automatic control, can solve problems such as incompatibility with batches, and achieve the effect of improving the efficiency of goods access, flexible operation and small batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

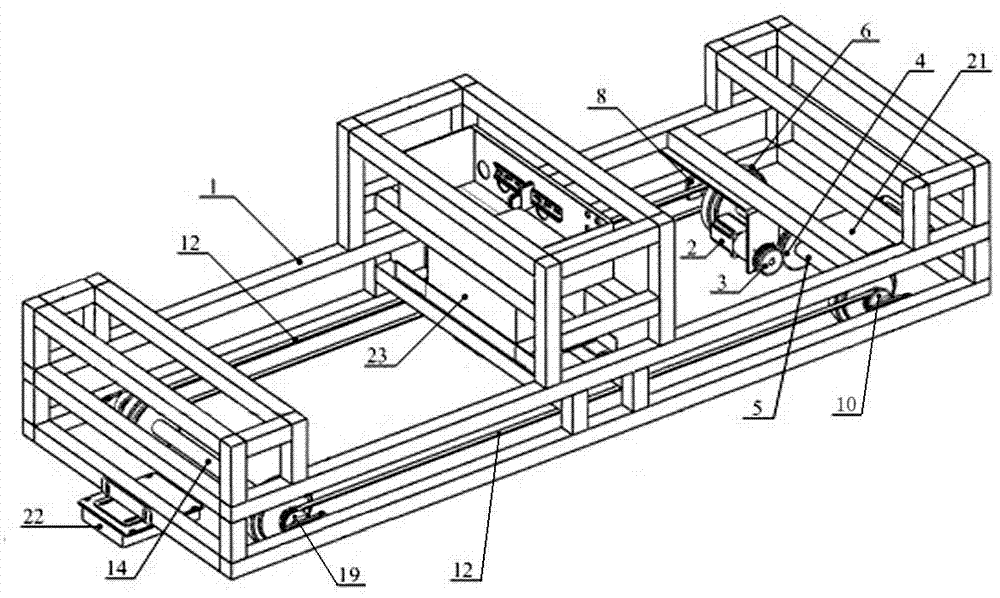

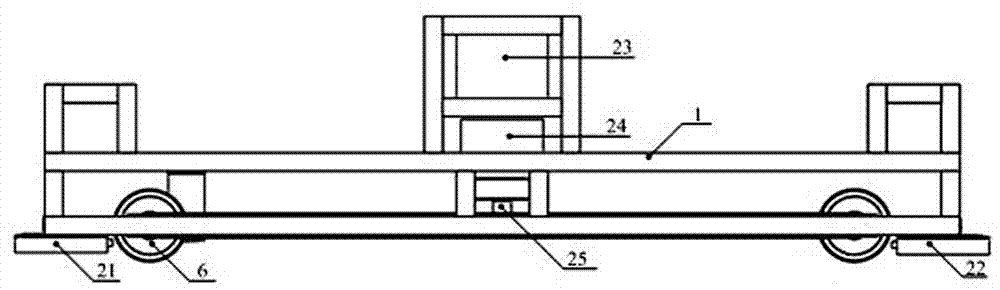

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

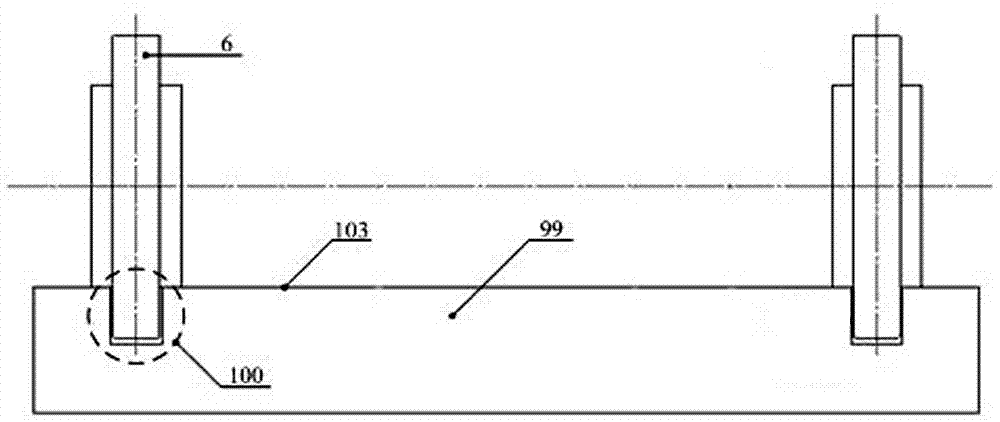

[0033] Such as Figure 1~3 As shown, based on the RFID double warehouse rail transport vehicle, it includes a vehicle frame 1 and a guide wheel 6 located at the bottom of the vehicle frame 1. There are 4 guide wheels 6, which are symmetrically installed around the bottom of the vehicle frame 1. The guide wheels 6 are formed by It consists of a large-diameter main wheel and two coaxial small-diameter wing wheels symmetrically fixed on both sides of the large-diameter main wheel, and is fixedly connected with the corresponding drive shaft through a key.

[0034] The frame 1 is a "mountain"-shaped frame structure, with two end convex frames and a middle convex frame, the end convex frame set at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com