Quilt winding machine winding device

A technology of winding device and winding machine, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve the problems of unable to complete the push-out operation, time-consuming and labor-consuming, and low operation efficiency, so as to achieve push-tightening Compaction operation, simple structure, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

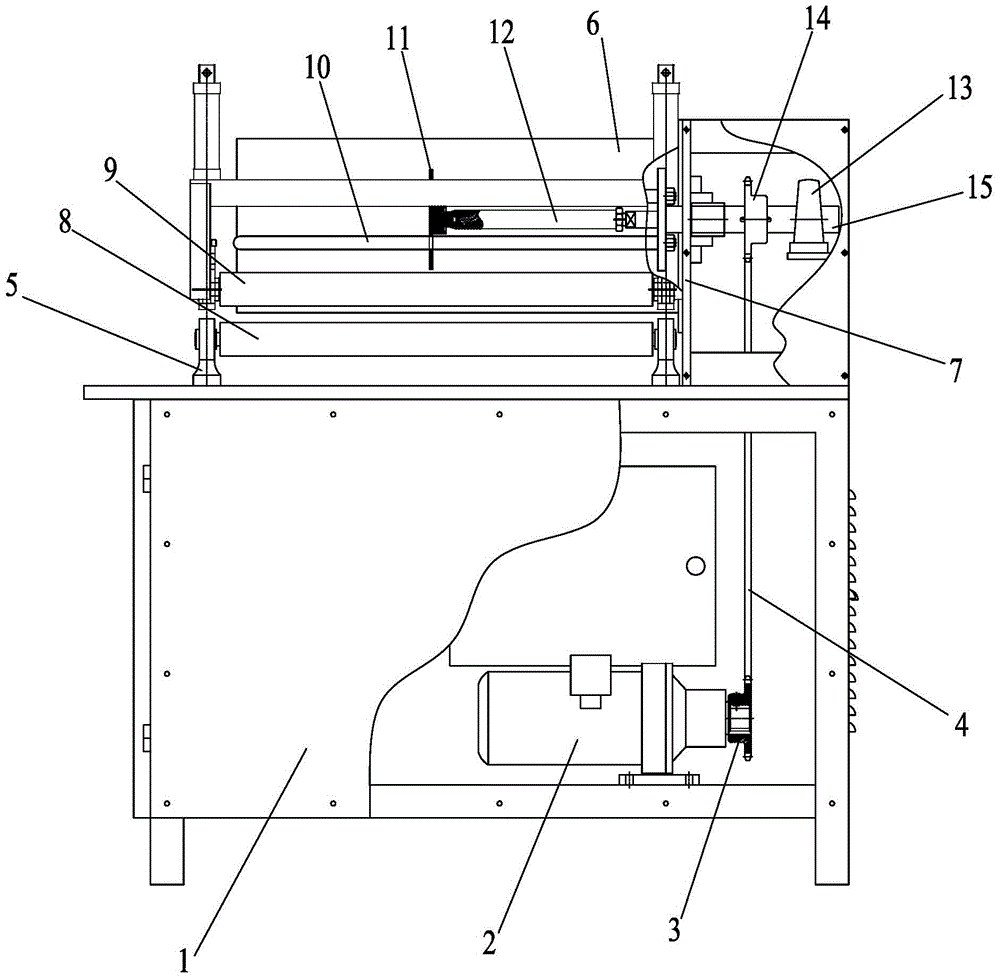

[0010] figure 1 It includes the frame 1, the reducer 2, the first gear 3, the chain 4, the outer spherical bearing seat 5, the roll baffle 6, the first bracket 7, the first clamped shaft 8, the second clamped shaft 9, the coil The being rod 10, the pushing plate 11, the pushing shaft 12, the bearing seat 13, the second gear 14, the pushing rod 15 and the like.

[0011] Such as figure 1 As shown, the present invention is a quilt winding machine winding device, including a frame 1, a reducer 2 is fixed on the bottom plate of the frame 1, the output end of the reducer 2 is connected to a first gear 3, and the frame 1 works An outer spherical bearing seat 5 is fixedly arranged on both ends of the table surface along the length direction. The first clamp is rotatably supported on the corresponding outer spherical bearing seat 5 by both ends of the shaft 8; a bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com