A kind of wire winding equipment and wire winding method for processing non-alkali glass fiber cloth

A technology of alkali-free glass fiber and wire winding equipment, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of large use restrictions, easy breakage, and reel winding work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

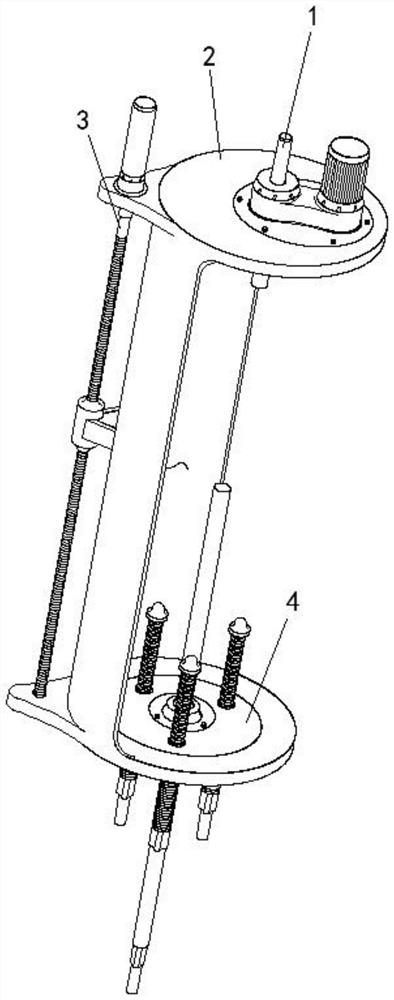

[0040] like Figure 1-7 As shown, a wire winding device for processing alkali-free glass fiber cloth includes a driving assembly 1 , a support frame 2 , a wire winding assembly 3 and a clamping assembly 4 .

[0041] The support frame 2 is arranged in a U shape, and the end of the support frame 2 is provided with a drive assembly 1, which is fixed at the end and extends into the support frame 2 for providing driving force; the other end of the support frame 2 is provided with a clamping assembly 4. The clamping assembly 4 is embedded in the end, and the clamping assembly 4 is bidirectionally protruded from the end of the supporting frame 2. It is located at the overhanging part of the inner side of the supporting frame 2, which is used to abut the reel and form a combined clamping with the driving assembly 1. body.

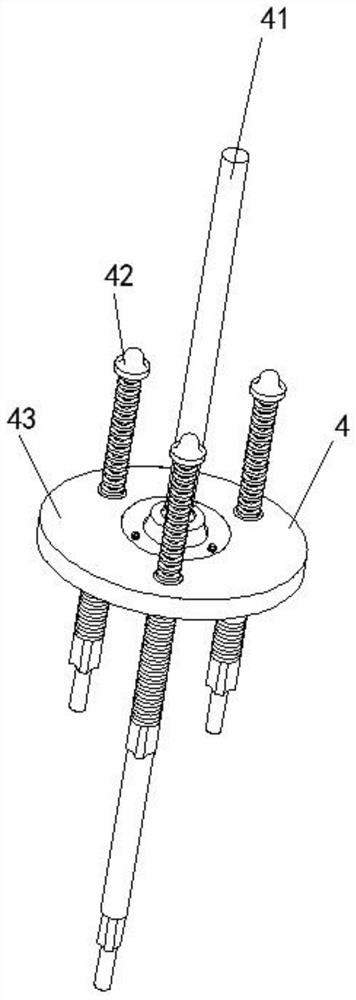

[0042] The clamping assembly 4 includes a turntable 43. The turntable 43 is embedded in the end of the support frame 2 and is rotatably connected with respect to ...

example 1

[0046] Example 1: For a reel whose length is less than the effective length in the support frame 2, the contact piece 42 can be rotated at the turntable 43 by force to adjust the relative position of the contact piece 42 to the turntable 43, and then the corresponding length can be adjusted. Short reel.

[0047] Example 2: For a reel with an uneven end surface, the relative positions of the plurality of contact pieces 42 can be adjusted to the turntable 43, so that when each contact piece 42 is in conflict with the end of the reel, the reel can be adjusted. fixed.

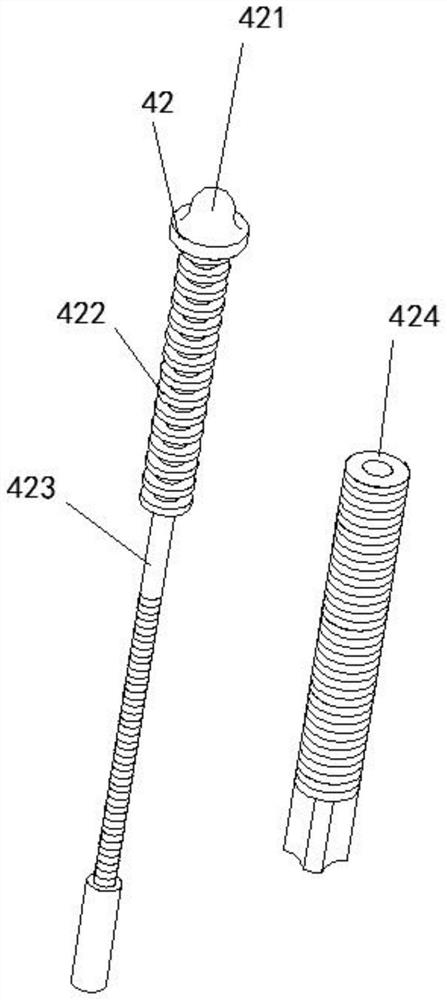

[0048] In this embodiment, it is not limited to adjusting the relative position by rotating the sleeve 424 with the turntable 43, but also the relative position can be further adjusted during the rotation of the threaded rod 423 compared to the rotating sleeve 424. The adjustment process is based on the elastic force exerted by the spring 422, and then relies on the tension force provided by the spring 422 to avoi...

Embodiment 2

[0050] like Figure 1-7 As shown, a kind of filament winding equipment for the processing of alkali-free glass fiber cloth, the outer side of the support frame 2 is provided with a wire winding assembly 3 parallel to the side wall of the support frame 2, and the wire winding assembly 3 is fixed at the support frame 2, and It extends into the support frame 2 and is used for introducing the wire into the support frame 2 .

[0051] The wire winding assembly 3 includes a screw rod 33, two brackets 32 are arranged symmetrically at both ends of the screw rod 33, and the two brackets 32 are symmetrically arranged at both ends of the support frame 2 to be fixed, and two ends of the screw rod 33 are respectively inserted into two The support frame 32 is connected in rotation relative to the support frame 32; the support frame 32 is provided with a linear motor 31 on the side facing away from the screw rod 33. The buffer assembly 34, the buffer assembly 34 is sleeved at the screw rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com