Brush wire winding device for heavy grinding brush machining

A technology of winding device and brush wire, applied in the direction of brushes, bristles, applications, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of improving efficiency, high degree of automation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

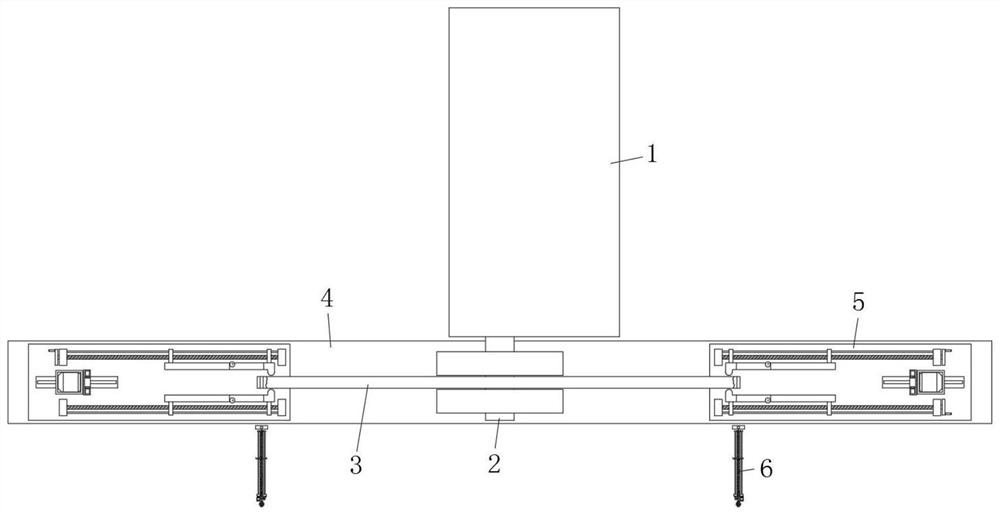

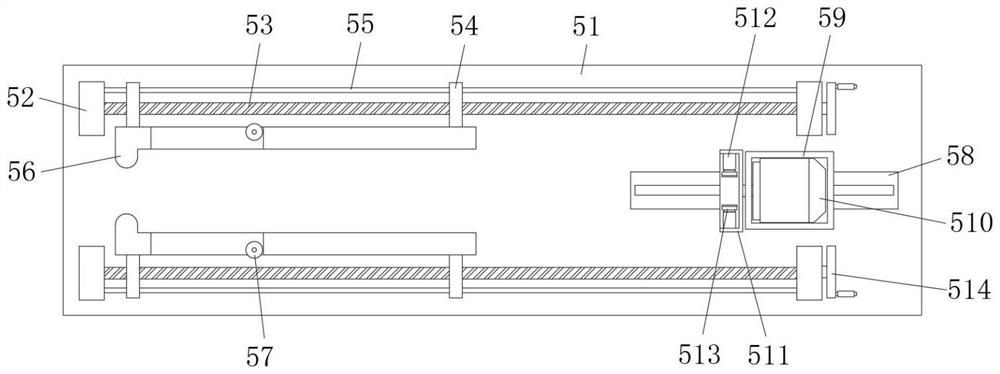

[0028] Reference Figure 1-5, a kind of brush wire winding device for heavy brush processing, including servo drive box 1, servo drive box 1 output end fixed with a rotating rod 2, rotating rod 2 outer wall fixed with a brush disc 3, servo drive box 1 front side is provided with a workbench 4, table 4 top surface is installed on both sides of the winding mechanism 5, winding mechanism 5 includes mount 51, mount 51 sliding damping is connected to the top surface of the workbench 4, mount 51 top surface is fixed to the support 52, the front and rear sides of the two supports 52 are rotated between the two sides of the connection with a threaded rod 53, Threaded rod 53 outer wall is connected by thread to the mounting sleeve 54, the front and rear mounting sleeve 54 also slides to connect the fin rod 55, and both sides of the limit rod 55 are fixed to the 52 side walls of the support, the front and rear side mounting set 54 is close to the mounting seat 51 The center side is fixed wit...

Embodiment 2

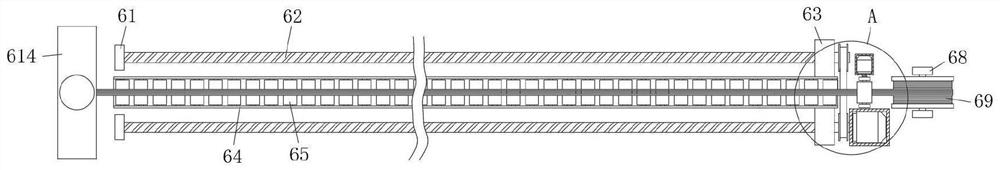

[0030] as Figure 1 、 3And 4 shown, the present embodiment and Example 1 is substantially the same, preferably, the wire feeding mechanism 6 includes a support seat 61, the same side of the two support seats 61 are rotated between the connection to the screw 62, the two screw 62 front ends are extended to the support seat one 61 outside and rotated connected to the conveyor belt, the two screw 62 outer wall is connected by thread 63, the advance plate 63 top surface is fixed with a wire feeding frame 64, the inner wall of the wire feeding frame 64 is also rotated and connected to the conveyor roller 65, and the front side of the pole 61 is also provided with an installation box two 66 , the inner wall of the installation box two 66 is fixed with a servo motor two 67 through screws, the servo motor two 67 output end is fixed with one of the screw 62, the support seat one 61 is also provided on both sides of the front end of the fixed seat 68, the fixed seat 68 is rotated and connect...

Embodiment 3

[0033] as Figure 3 and 5 As shown, the present embodiment and Example 1 are substantially the same, preferably, the slitting component 614 includes a mounting bracket 6141, the outer top surface of the mounting frame 6141 is screwed with a cylinder 6142, the output of the cylinder 6142 is fastened by a screw with a slitting knife 6143, and the inner wall of the mounting frame 6141 is also fixed with a plate 6144.

[0034] In the present embodiment, after the completion of the feeding, the cylinder 6142 drives the slitting knife 6143 down to achieve rapid slitting of the brush wire, thereby realizing the continuous conveying operation of the brush wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com