Fire hose fastening machine

A technology for fire hoses and tying machines, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient disassembly and replacement of wire reels, time-consuming and labor-intensive, inconvenient use, etc., so as to save workplace and equipment costs, and is convenient The effect of automatic control and improving the degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are further described below in conjunction with accompanying drawing:

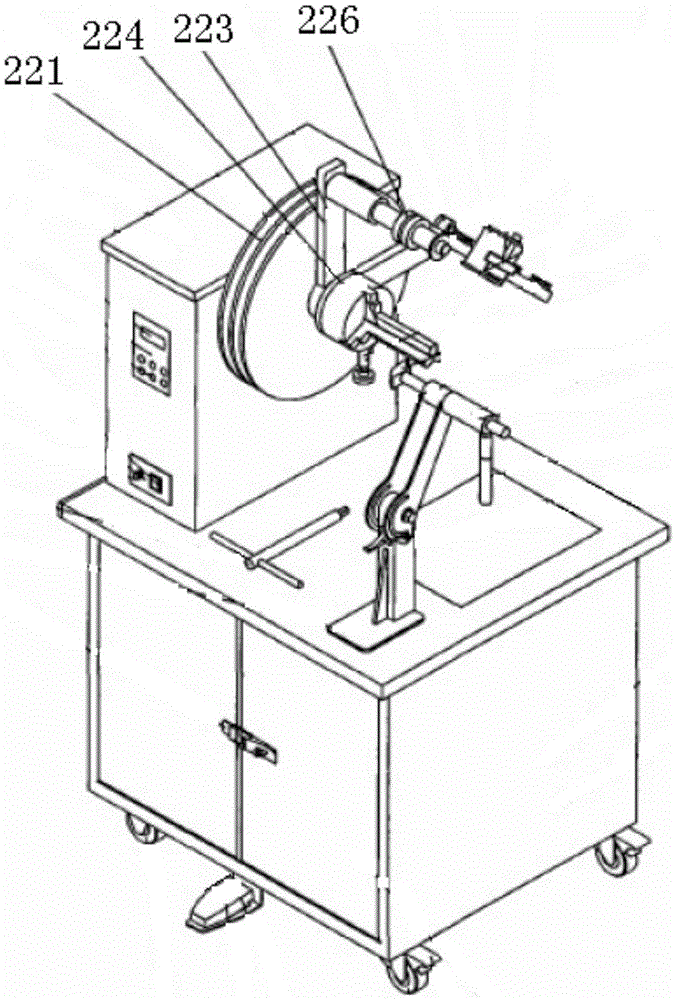

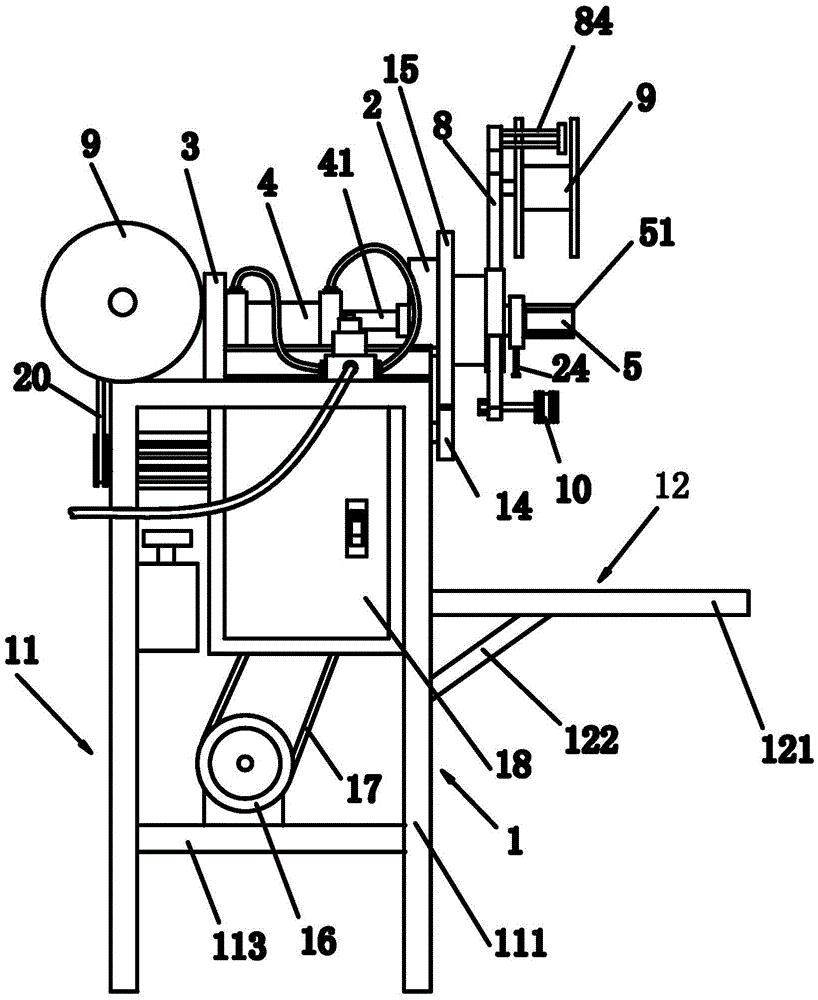

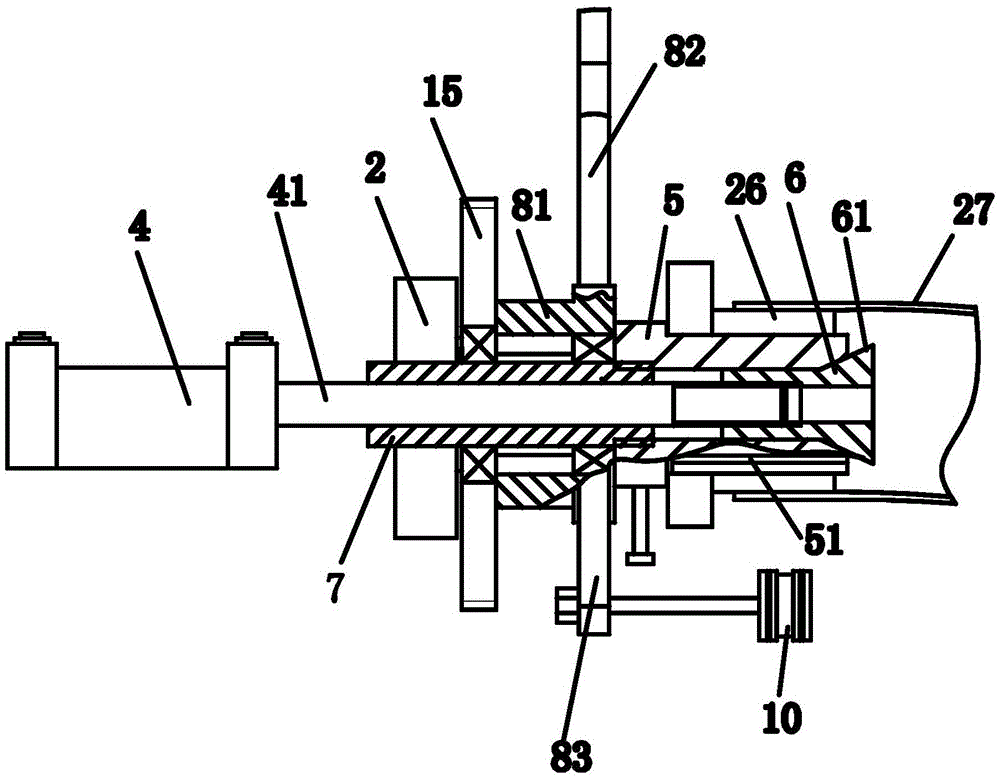

[0022] Such as Figure 2 to Figure 5 As shown, a fire hose fastening machine includes a frame 1, a transmission system, a control system, a clamping mechanism, a reel 9 and a winding arm 8. Among them, the transmission system and the control system are installed on the frame 1, the control system is used to control the operation of the transmission system and the clamping mechanism, the transmission system can drive the rotation of the winding arm 8, and the clamping mechanism can clamp and fix the buckle . In order to simplify the structure, save materials and cost, but do not affect the firmness of the frame 1, the frame 1 is made of steel such as angle steel and channel steel, and the frame 1 includes a bedside frame 11 and a workbench frame 12. Bench 12 is fixed on one side of bedside frame 11, and workbench frame 12 has two cantilever beams 121 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com