Firing method of multi-layer glaze ceramic

A glaze and ceramic technology, applied in the field of ceramic products, can solve the problems of poor fracture toughness and low yield, and achieve the effect of increasing the firing yield, enhancing strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

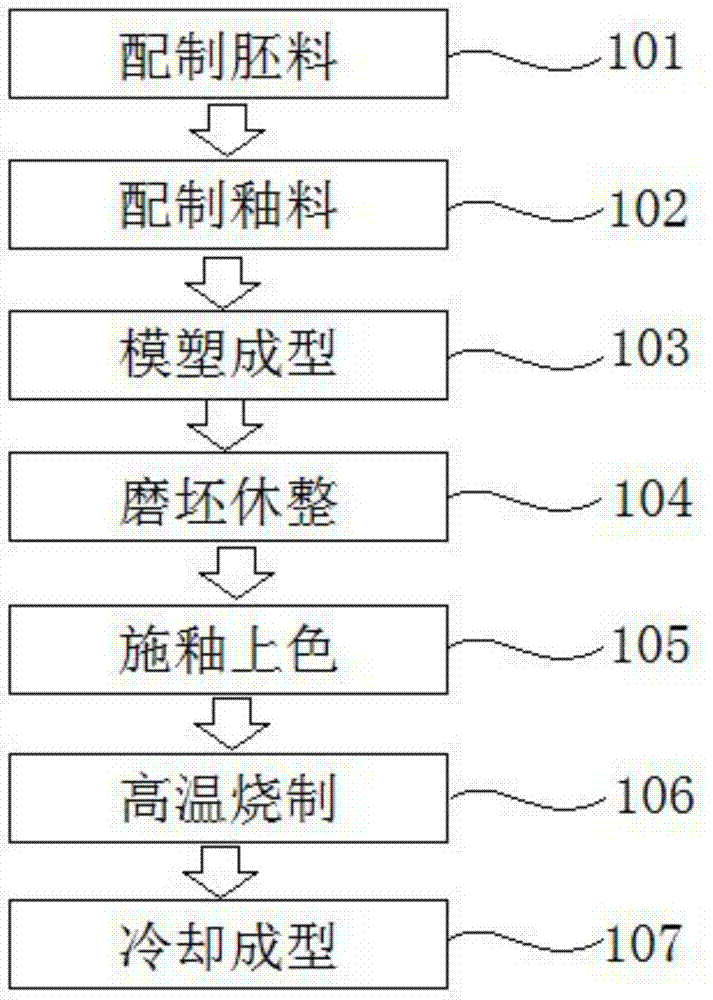

[0029] refer to figure 1 Shown, a kind of firing method of multilayer glaze ceramics, comprises the following steps:

[0030] 101. Preparing blanks: Accurately weigh the raw materials of the ceramic blanks according to parts by weight, pretreat the blanks, mix, pulverize, grind, and sieve to obtain the mixed blank raw materials;

[0031] 102. Glaze preparation: accurately weigh the raw materials for the glaze layer by weight, and mix, pulverize, grind, and sieve the raw materials for the mixed glaze layer after pretreatment with the glaze;

[0032] 103. Molding: making and molding the above-mentioned raw material of the embryo body, and drying it to obtain a green billet;

[0033] 104. Grinding blank rest: use tools to smooth the above green b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com