Energy-saving type air-jet loom weft yarn inserting system

A technology of air-jet loom and weft insertion system, which is applied to looms, textiles, textiles, and papermaking, and can solve problems such as insufficient weft insertion capacity, waste of air volume, and unstable air supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

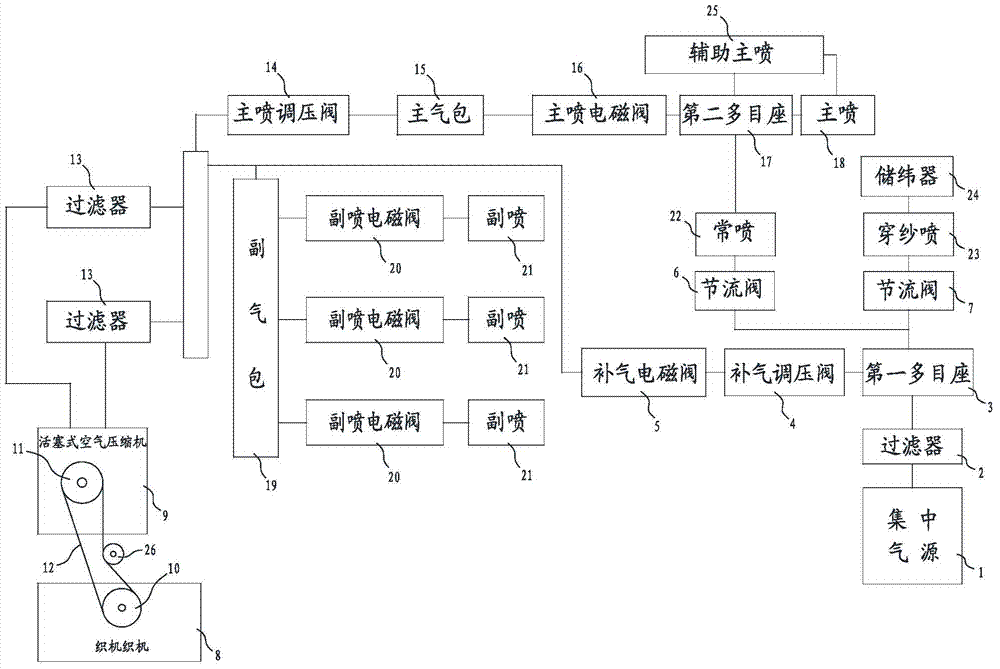

[0030] to combine figure 1 As shown, an energy-saving air-jet loom weft insertion system includes a centralized air supply system and a piston air compressor weft insertion air supply system.

[0031] Centralized air supply system, used for centralized air supply. The system includes centralized air source 1, filter 2, first multi-purpose seat 3, air supplement pressure regulating valve 4, air supplement solenoid valve 5, constant spray throttle valve 6, yarn threading spray throttle valve 7, regular spray 22 And threading jet 23.

[0032] The centralized air source 1, the filter 2 and the first multi-purpose seat 3 are connected in sequence.

[0033] The first multi-purpose seat 3 includes three gas outlet branches.

[0034] One of the air outlet branches is connected with the air supply regulating valve 4 for adjusting the air supply press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com