Large package lifting control system outside the machine

A control system and large package technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of wrinkling and deformation of the cloth surface, increase the load of friction rollers and winding rollers, and achieve the effect of preventing wrinkling and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

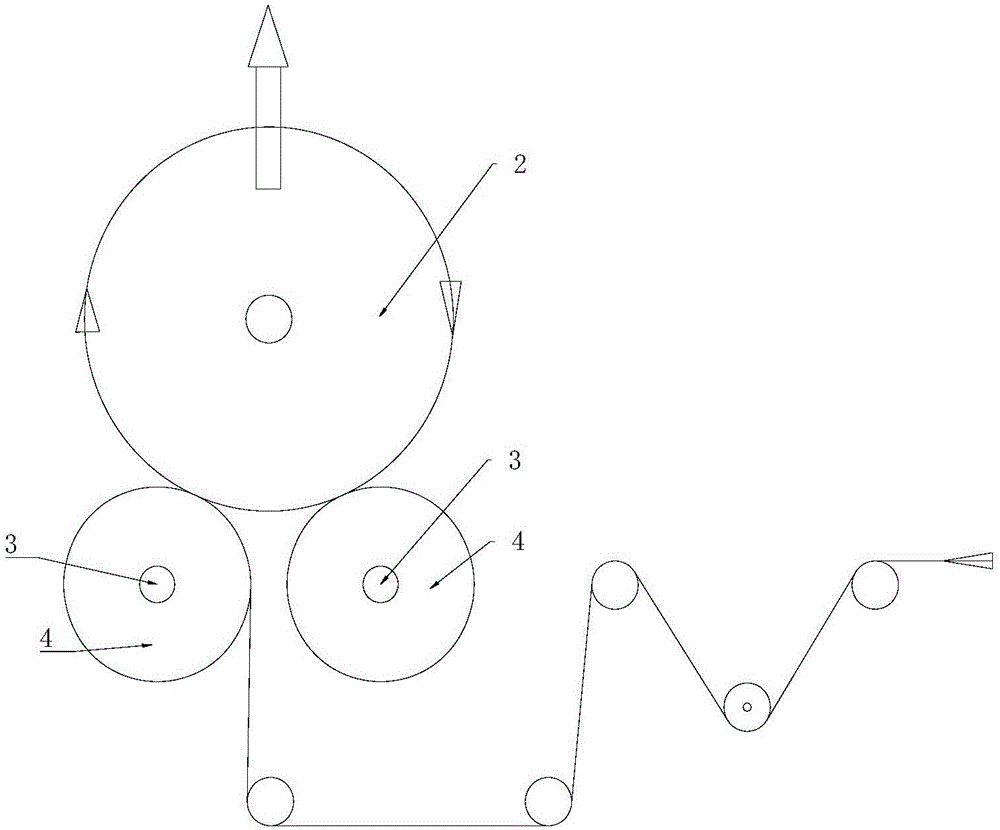

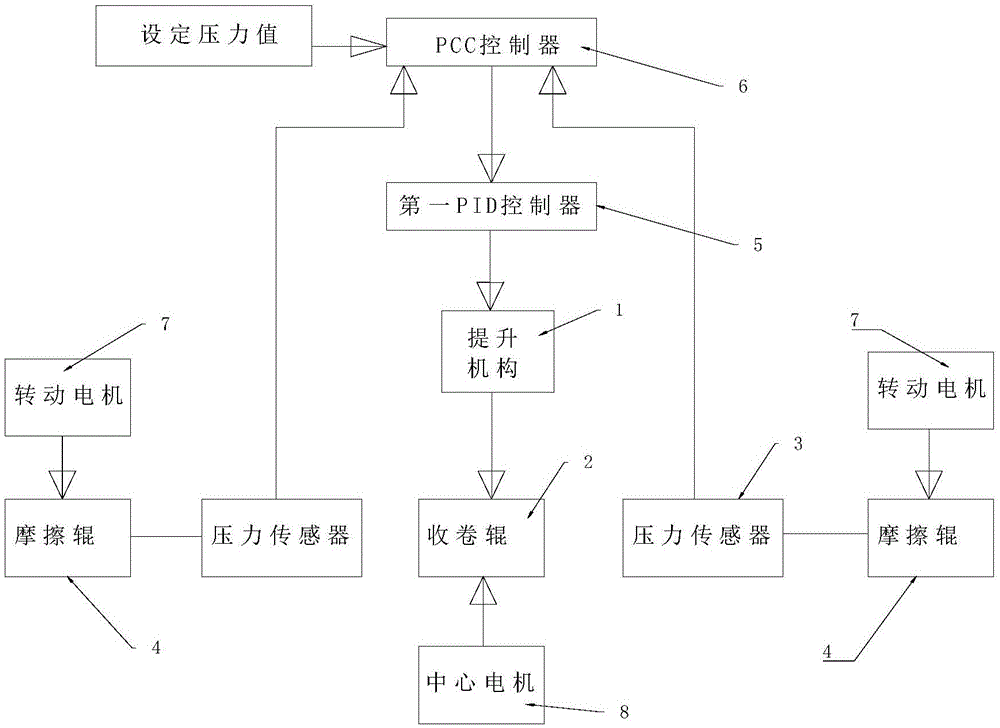

[0015] It can be seen from the figure that the lifting control system of the large package outside the machine of the present invention includes a winding roller 2 with a lifting mechanism 1, a friction roller 4 with a pressure sensor 3, a PID controller 5 for controlling the lifting mechanism 1, and simultaneously with the pressure The PCC controller 6 connected with the signal of the sensor 3 and the PID controller 5, the friction roller 4 is provided with a rotating motor 7, and the winding roller is provided with a central motor 8, and the fabric thickness and initial pressure are preset by the PCC controller 6, The winding roller 2 is in tight contact with two friction rollers 4, and the pressure between the friction roller 4 and the winding roller 2 is equal to the initial pressure. The central motor 8 drives the winding roller to rotate, and the rotating motor 7 drives the friction roller to rotate. The winding roller and the friction roller rotate and cooperate to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com