A wool product processing method based on humidification of cutting pieces and finished products

A processing method and technology of wool, applied in textiles and papermaking, cutting of textile materials, heating/cooling of fabrics, etc., can solve the situation that the expansion and contraction of the fabric after being damp is not considered, the shrinkage of the size is not strictly consistent with the calculated value, and the humidification treatment conditions Control the problem of inconsistency to achieve the effect of ensuring fit and comfort, dimensional stability, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

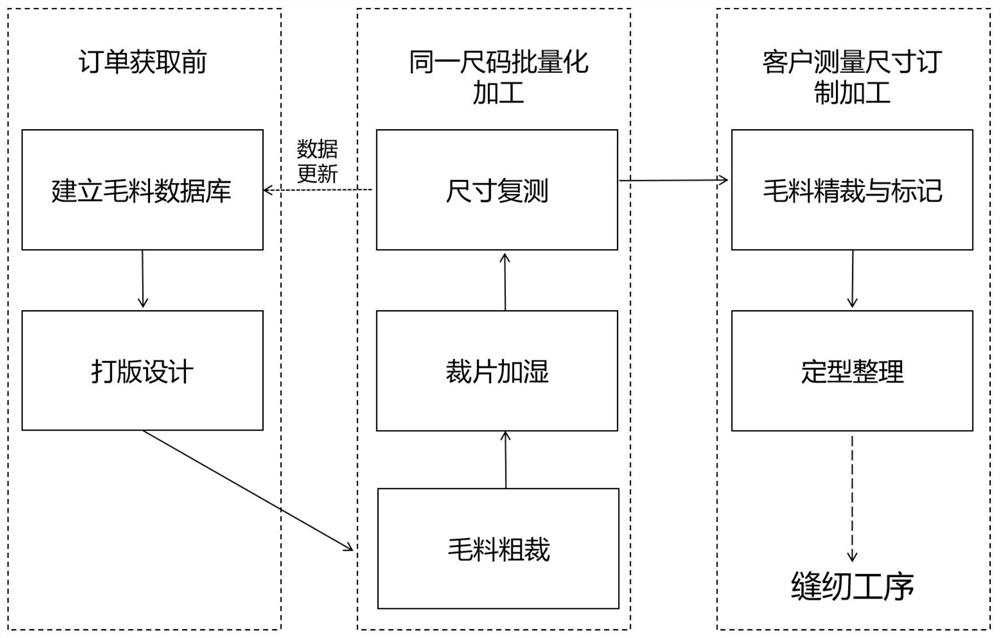

[0027] combine figure 1 As shown, the technical scheme of the present invention is described in detail by taking 70% wool blended wool with a thickness of 1mm as an example. The wool product processing method based on cutting pieces and finished product humidification according to the present invention comprises the following steps:

[0028] Step 1. Establish a wool database, including the type, weight, water absorption, and radial shrinkage S of 70% wool blended wool J , Radial shrinkage rate standard deviation δ J , Weft shrinkage rate S W , standard deviation of weft shrinkage rate δ w , the best humidification treatment method, and the data of the best humidification treatment conditions; among them, the type, weight and water absorption of the wool are provided by the wool supplier, and the radial shrinkage S J , Radial shrink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com