Lightweight concrete step and manufacturing method thereof

A technology for concrete and stairs, which is applied in the direction of stairs, ladder-like structures, treads and riser units, etc. It can solve the problems of poor overall mechanical structure of concrete stairs, complicated connection methods between steps and terraces, and unsuitable concrete staircase structures, etc. problems, to achieve the effect of increasing aesthetics, convenient and quick lifting, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

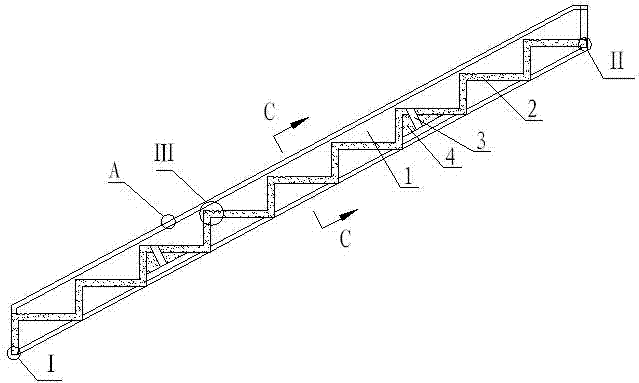

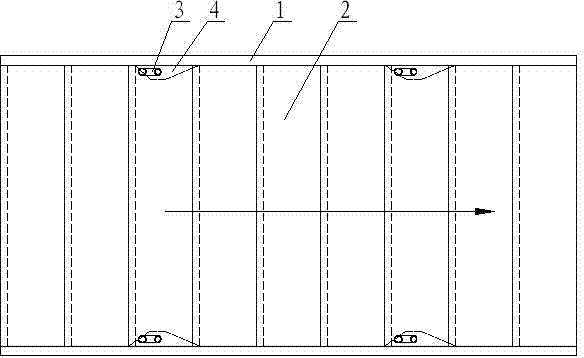

[0029] like figure 1 , figure 2 As shown, a light-weight concrete staircase is an integral structure composed of a side plate beam 1 and a ladder plate 2. The step board 2 is provided with a tread reinforcement 7, and the side plate girder 1 is provided with a truss type reinforcement 6, and the tread reinforcement 7 is connected with the truss type reinforcement 6 as a whole.

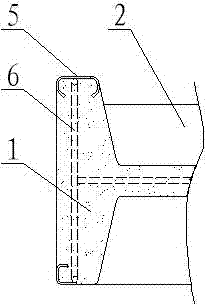

[0030] like image 3 , Figure 4 , Figure 5 , Figure 7 As shown, the edges of the side girder 1 and the ladder plate 2 are provided with wrapping edges 5 for preventing collision and enhancing strength. The wrapping 5 can be made of bent steel plates or other shaped steels. Both sides of the wrapping 5 are comb-shaped and extend into the inside of the concrete. The comb-like shape can make the wrapping 5 and the concrete combine more tightly and firmly. The hemming 5 is welded together with the side plate beam 1, the pedal steel bar 7 inside the ladder plate 2, or the truss type steel bar 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com