Quick wall whitewashing machine

A wall brushing machine, fast technology, applied in the direction of construction, building construction, etc., can solve the problems that affect the actual effect of painting, large roller volume, missing brushes, etc., to achieve the effect of speeding up the progress of wall painting, common materials, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

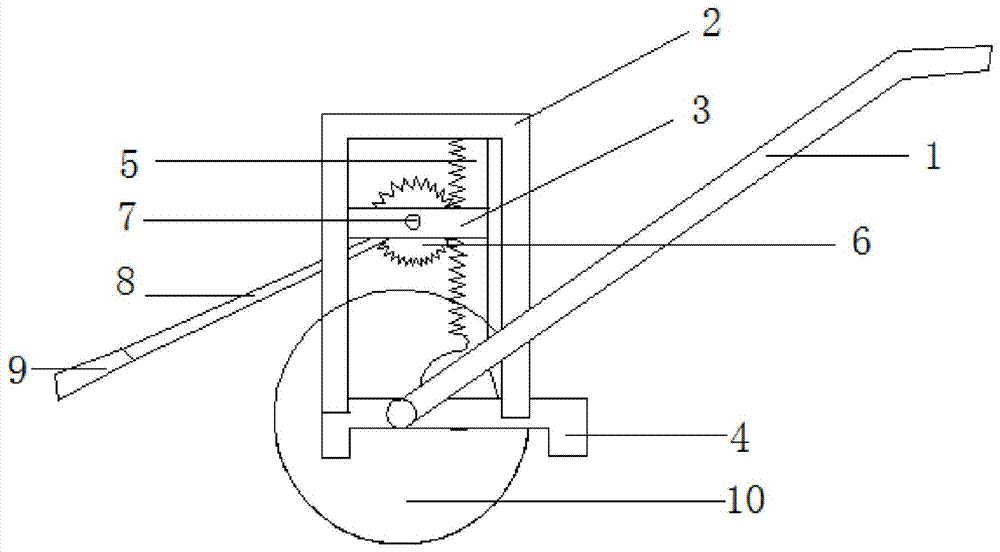

[0015] Such as figure 1 Shown, a kind of fast brushing machine, comprises handle 1 and roller 10, also comprises gear 6, pin shaft, fixed shaft 7, fixed frame 2 that is pinned with roller 10 and rack 5 that is bolted with roller 10, The fixed frame 2 is provided with a fixed block 3 and a brake block 4, the brake block 4 is located around the roller 10, the fixed block 3 is connected with the gear 6 through the fixed shaft 7, the gear 6 rotates around the fixed shaft 7, and the gear 6 and the rack 5 meshes, the gear 6 is provided with a strut 8, the strut 8 is connected with a brush 9, and the handle 1 is connected with the fixed frame 2 through a pin shaft.

[0016] The length of the fixed block 3 is greater than the diameter of the addendum circle of the gear 6, which facilitates the meshing rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com