Gas filtering device with automatic temperature regulating function

A filter device and automatic adjustment technology, which is applied in the direction of oil supply device, charging system, engine components, etc., can solve the problem of many connecting pipes and control lines between the gas filter device and the carburetor, the large space occupied by the control components, and the large overall volume of the equipment, etc. problem, achieve the effect of reducing connecting pipes and control lines, simple assembly and disassembly, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

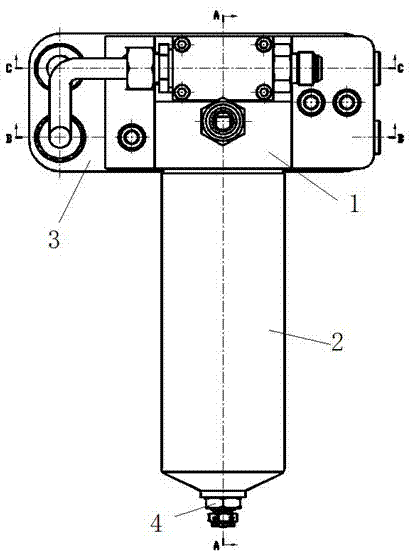

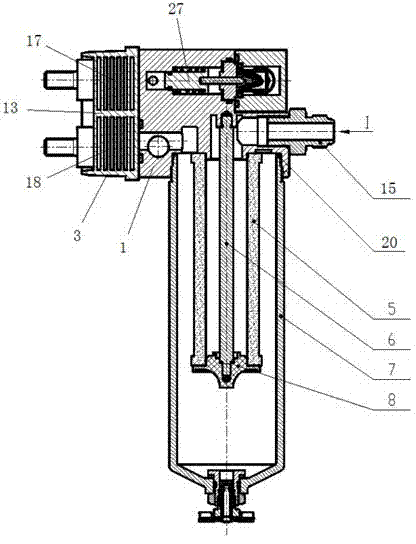

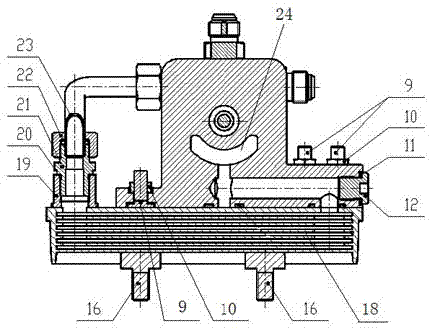

[0017] The structure diagram of the gas filter device with automatic temperature adjustment of the present invention is as follows figure 1 and figure 2 As shown, it includes a base 1 and a gas filtering device 2 connected under the base 1. The gas filtering device 2 includes a housing 7 screwed to the base 1, and a filter element 5 arranged in the housing 7. The filter element 5 has two One end of the filter element 5 adopts an interference fit with the base 1, and the other end presses the lower sealing cover 8 on the filter element 5 through the support rod 6; the filtration accuracy, filtration efficiency and rated flow rate of the filter element 5 And other performance can be designed according to the requirements of the main engine factory, which can meet the needs of different types of engines. see image 3 , a heat exchanger 3 is connected to the side of the base 1, and connecting screws 9 connected to the base 1 and butt screws 16 connected to the engine are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com