Infrared energy gathering combustor

An infrared and burner technology, used in burners, burners, gas fuel burners, etc., can solve problems such as high maintenance costs, explosive porcelain, and inability to remove from the burner, saving maintenance costs and ensuring use. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

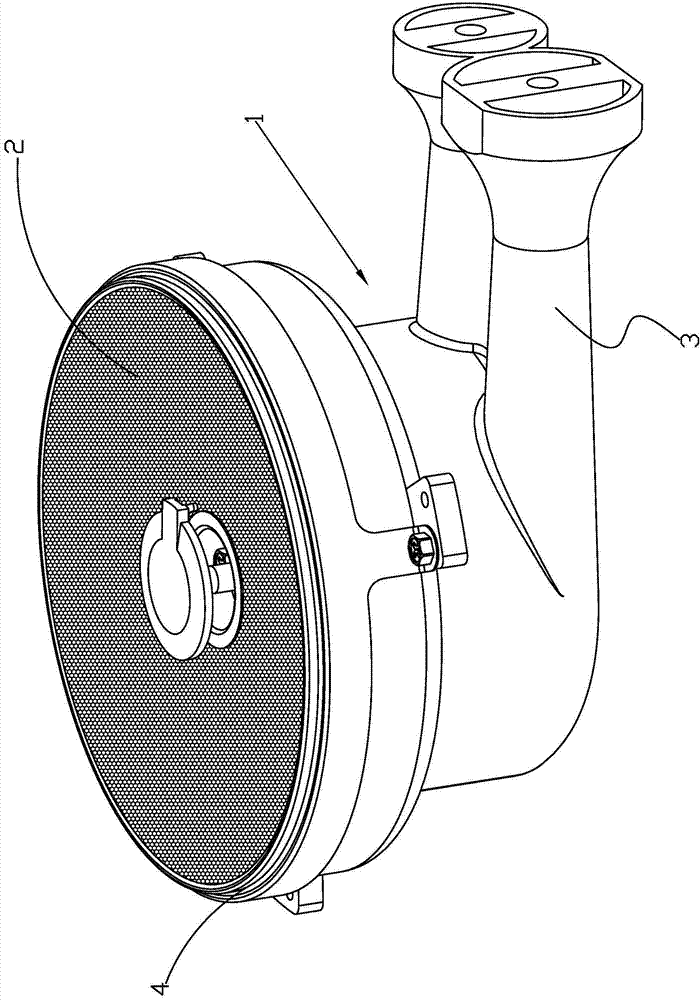

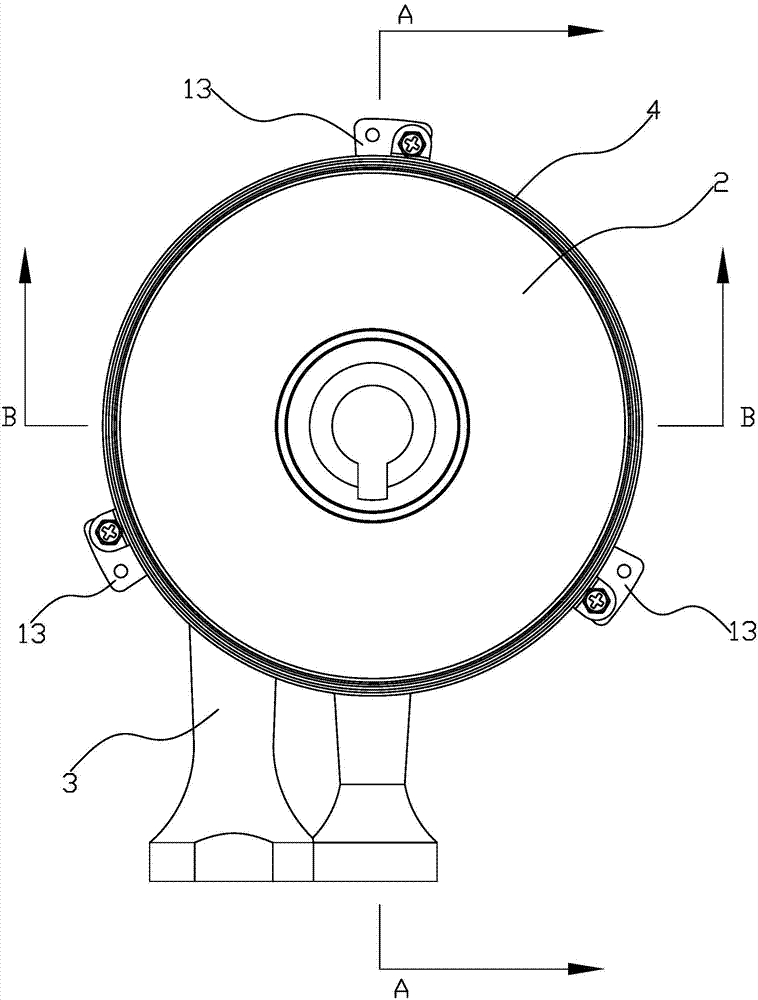

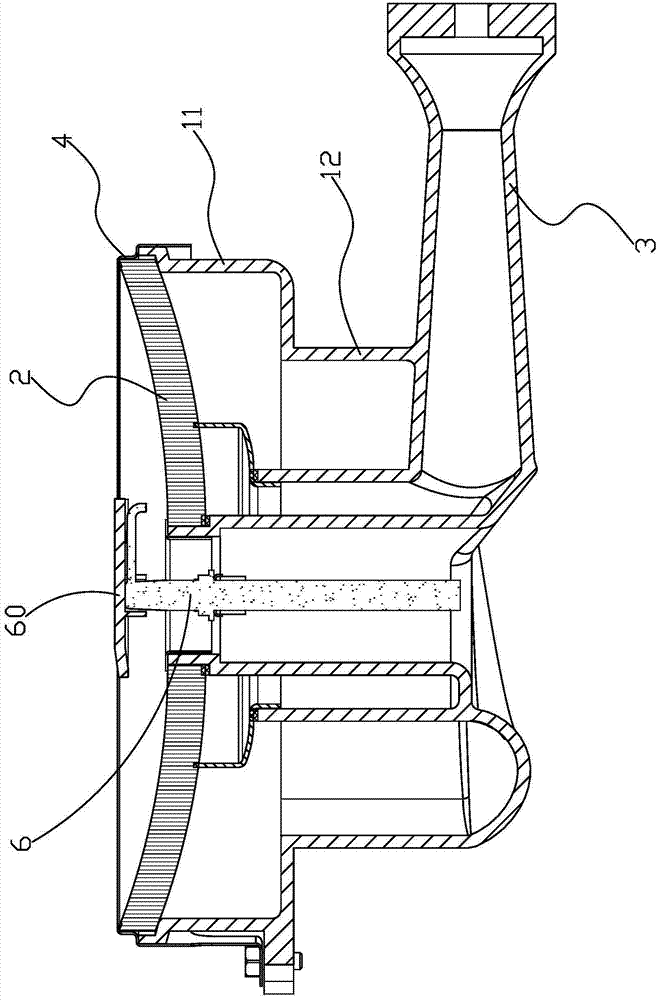

[0027] refer to figure 1 As shown in Fig. 9, the infrared concentrated energy burner includes a burner main body 1 which is hollow inside. The burner main body 1 is integrally cast and formed and the shape of the burner main body 1 is in the shape of a round platform with a large upper part and a smaller lower part. The burner main body 1. At the opening of the end face of the large-diameter section 11 on the upper part, there is an infrared generator 2 that can generate infrared rays after being heated. On the side wall of the small-diameter section 12 on the lower part of the burner main body 1, an ejector tube for conveying gas is connected. 3. The injection tube 3 communicates with the interior of the burner body 1 . Since the burner main body 1 of the present invention adopts an integrally cast structure, the burner main body 1 will not be deformed or cracked even if it is baked at a high temperature for a long time, which effectively prevents leakage caused by the crack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com