Internal-cooled solution dehumidifying assembly

A technology of solution dehumidification and unit, which is applied in the field of dehumidification equipment and internal cooling solution dehumidification unit, which can solve the problems of low efficiency, difficult control of system operating parameters, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

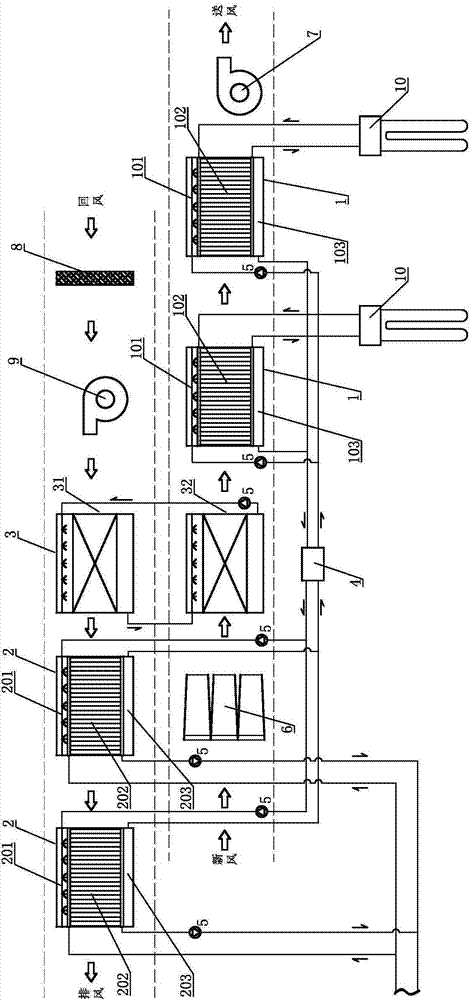

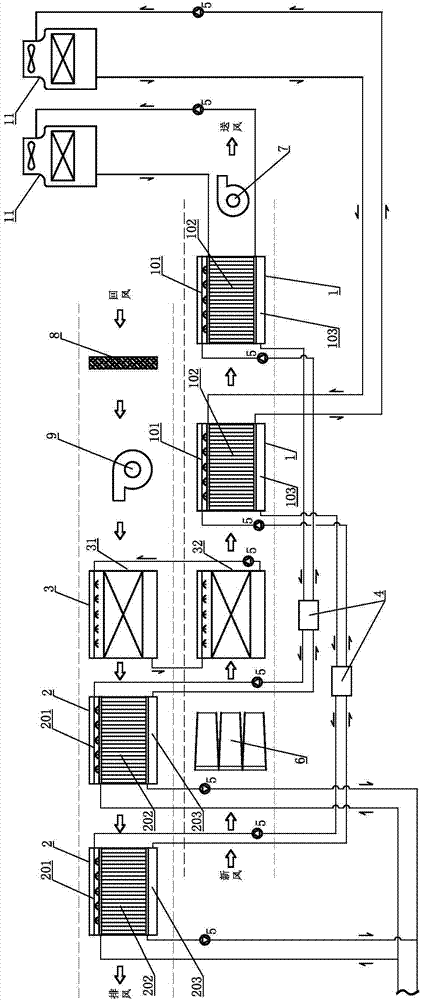

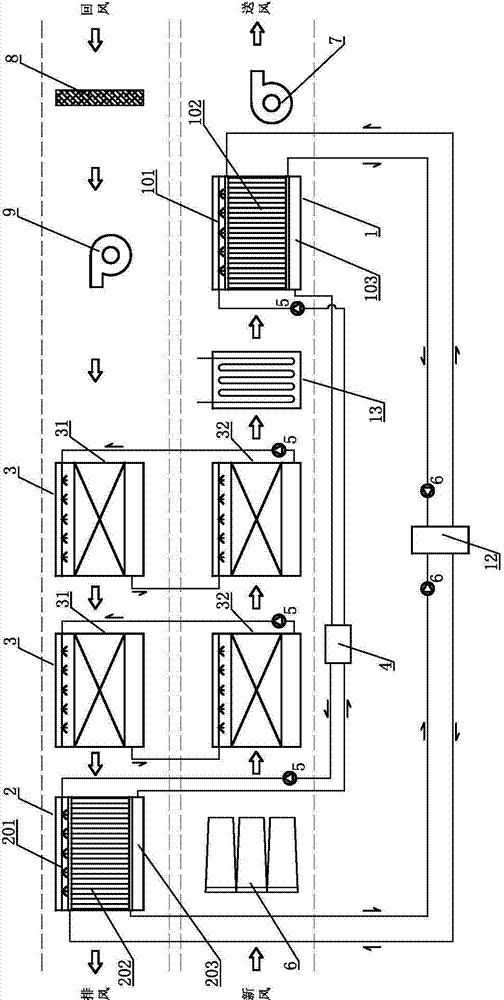

[0049] Such as figure 1 In the schematic diagram of the first embodiment of an internal cooling solution dehumidification unit shown in the present invention, there are two sets of solution dehumidification units 1, two sets of solution regeneration units 2, one set of solution heat recovery units 3, and solution dehumidification units 1 The first solution spraying device 101, the first heat exchange device 102, and the first solution tank 103 are provided in sequence from top to bottom; the solution regeneration unit 2 is provided with a second solution spraying device 201, a second exchange The thermal device 202 , the second solution tank 203 , and the solution heat recovery unit 3 include an upper heat recovery device 31 and a lower heat recovery device 32 with the same structure.

[0050] Between the two sets of solution dehumidification units 1 and the two sets of solution regeneration units 2, a mixed solution dehumidification regeneration loop is arranged through pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com