Glue pot convenient to fast and efficiently stir for electronic product production

An electronic product, fast technology, applied in the direction of mixers with rotating stirring devices, mixer accessories, material forming presses, etc., can solve the problem of not having vacuum stirring function, not having drying and sterilization function, not having heating function, etc. problems, to achieve the effects of stirring, improving sterilization and dehumidification, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

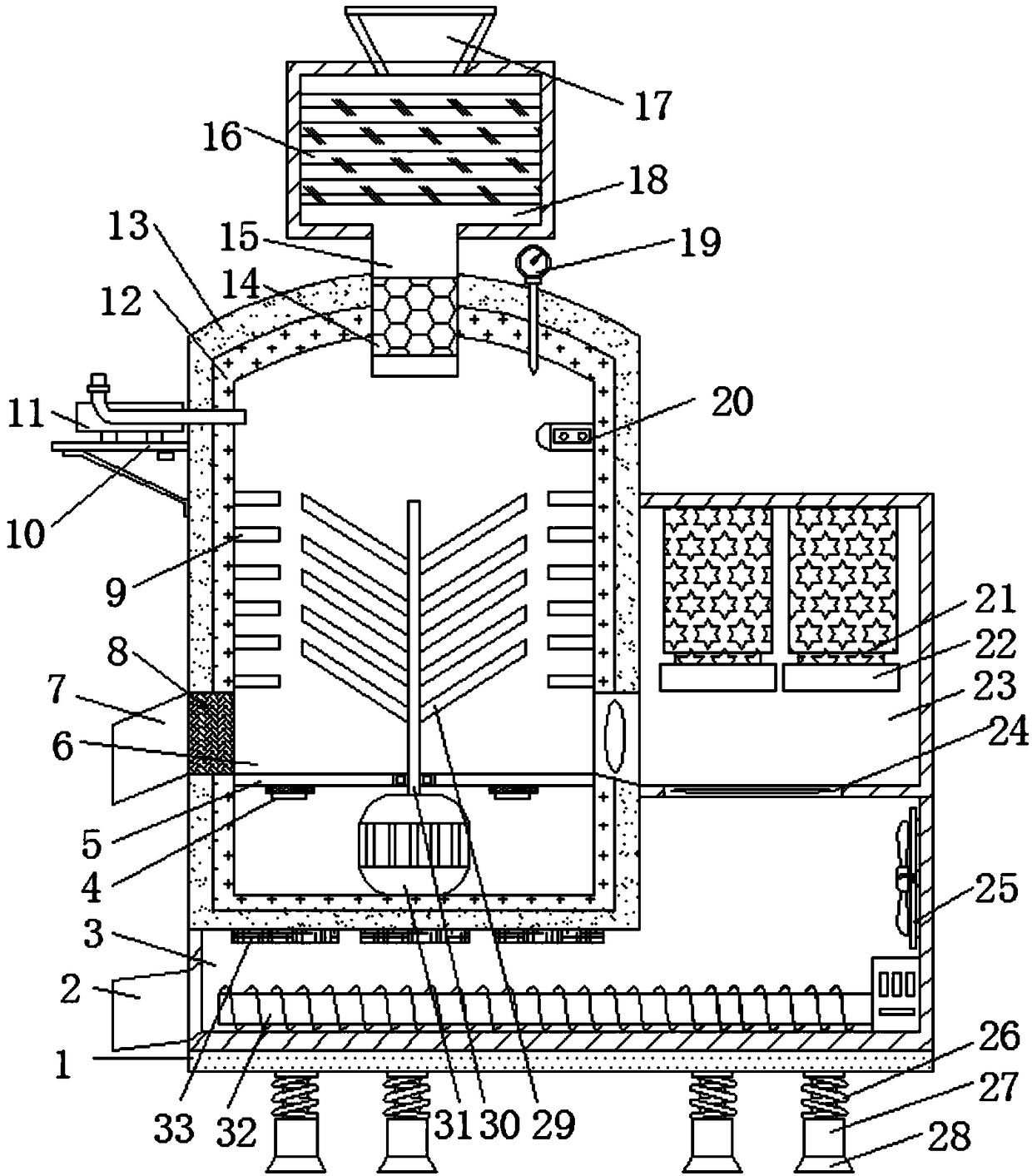

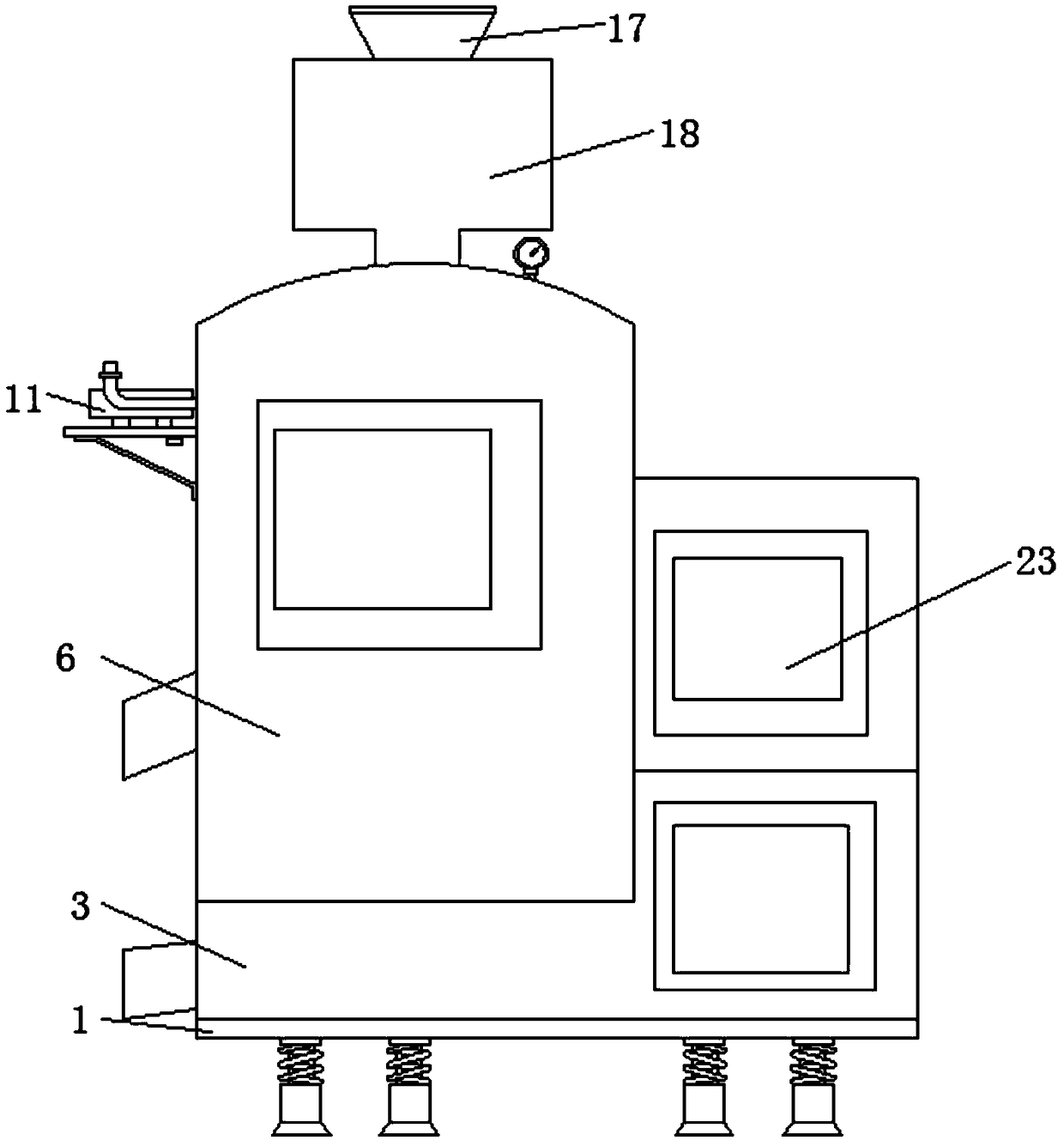

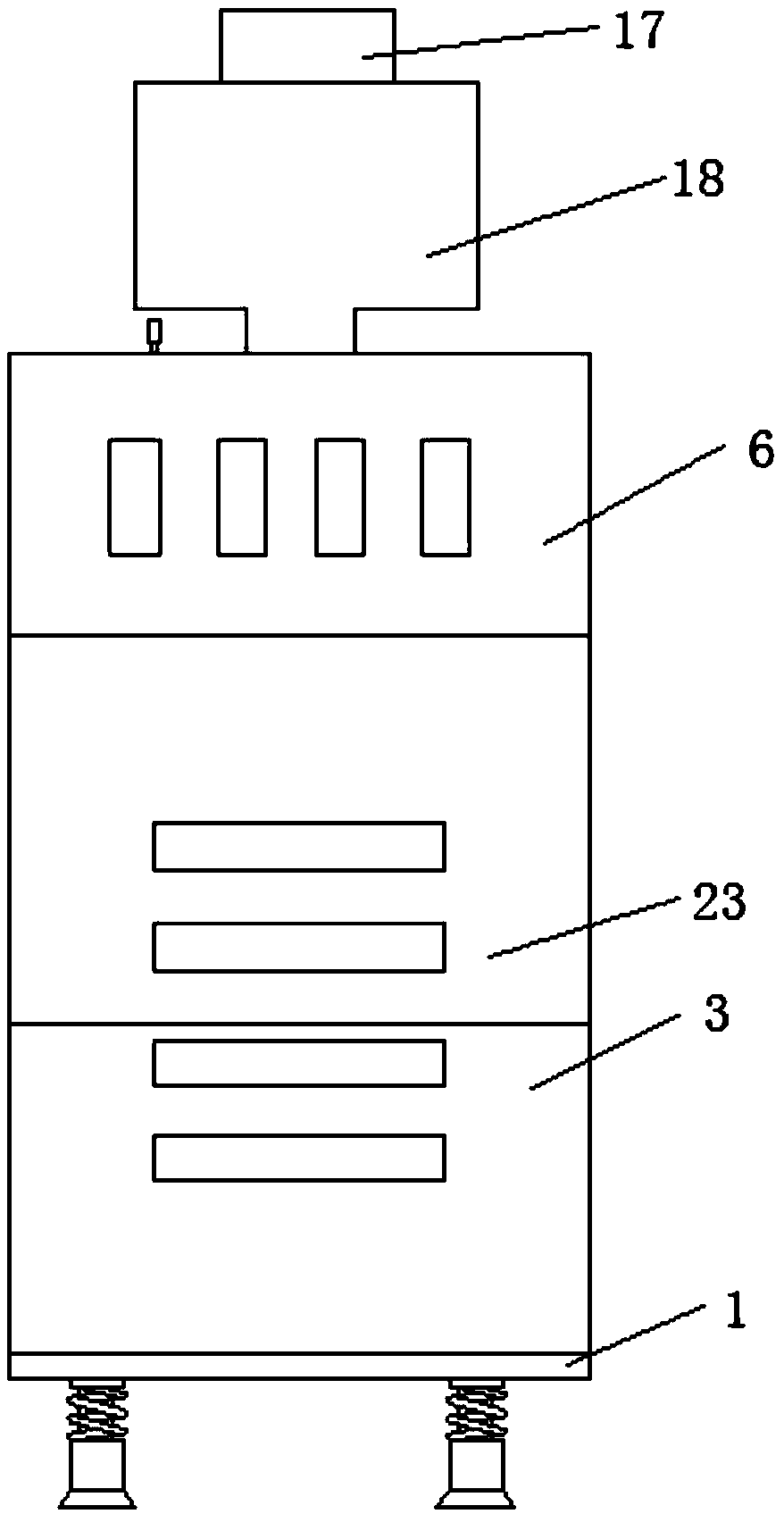

[0027] refer to Figure 1-5 , a plastic tank for the production of electronic products that is convenient for rapid and efficient mixing, including a bottom plate 1, a delivery box 3 is welded on the top outer wall of the bottom plate 1, and the delivery box 3 is in an inverted L shape, and one side of the top outer wall of the delivery box 3 is welded with Stirring box 6, and one side of delivery box 3 top outer wall is welded with extrusion box 23 near the position of stirring box 6, has the first mounting hole on the top outer wall of stirring box 6, and inserts on the circumference inner wall of the first mounting hole Connected with feeding pipe 15, the side inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com