A modified atmosphere curing agent used in the process of tobacco leaf storage and alcoholization and its preparation method

A production method and technology of a curing agent, which are applied in the directions of tobacco, application, and treatment of tobacco, can solve the problems of slow dehumidification and dehumidification, increased use of deoxidizers and moisturizing agents, and agglomeration of deoxidizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

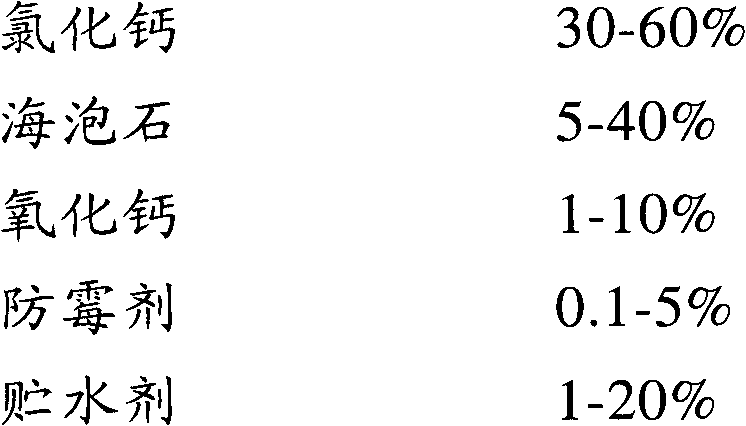

[0045] In this embodiment, the compound oxygen-reducing agent, airway forming agent, and moisturizing agent in the oxygen-reducing and insecticidal maintenance agent are formulated according to the proportion of 6:3:1, wherein the compound oxygen-reducing agent is formulated according to the following weight percentages:

[0046] Reduced iron powder (100 mesh) 99%

[0047] Stannous Chloride 1%

[0048] The airway forming agent is formulated according to the following weight percentages:

[0049] Sepiolite (10 mesh) 50%

[0050] Carbonized rice husk powder (100 mesh) 50%

[0051] Moisturizing agent is formulated according to the following weight percentages in the oxygen-reducing insecticide curing agent:

[0052] Sodium saltpeter 50%

[0053] water 50%

[0054] Mix the compound oxygen reducing agent and the airway constructing agent evenly, then add the moisturizing agent, and mix evenly. The above-prepared oxygen-reducing insecticide curing agent is packed in a small pa...

Embodiment 2

[0062] In this embodiment, the compound oxygen-reducing agent, airway forming agent, and moisturizing agent in the oxygen-reducing insecticide curing agent are proportioned according to the proportion of 4:4:2, wherein the compound oxygen-reducing agent is proportioned according to the following weight percentages:

[0063] Reduced iron powder (80 mesh) 95%

[0064] SnCl 5%

[0065] The airway forming agent is formulated according to the following weight percentages:

[0066] Sepiolite (20 mesh) 25%

[0067] Carbonized rice husk powder (60 mesh) 75%

[0068] Moisturizing agent is formulated according to the following weight percentages in the oxygen-reducing insecticide curing agent:

[0070] water 90%

[0071] Mix the compound oxygen reducing agent and the airway constructing agent evenly, then add the moisturizing agent, and mix evenly. Put the oxygen-reducing insecticide maintenance agent prepared above in a small package PE film bag (th...

Embodiment 3

[0078] In this embodiment, the compound oxygen-reducing agent, airway forming agent, and moisturizing agent in the oxygen-reducing and insecticidal maintenance agent are formulated according to the proportion of 8:1:1, wherein the compound oxygen-reducing agent is formulated according to the following weight percentages:

[0079] Reduced iron powder (200 mesh) 98%

[0080] SnBr 2%

[0081] The airway forming agent is formulated according to the following weight percentages:

[0082] Sepiolite (30 mesh) 40%

[0083] Carbonized rice husk powder (200 mesh) 60%

[0084] Moisturizing agent is formulated according to the following weight percentages in the oxygen-reducing insecticide curing agent:

[0085] Sodium saltpeter 90%

[0086] water 10%

[0087] Mix the compound oxygen reducing agent and the airway constructing agent evenly, then add the moisturizing agent, and mix evenly. The above prepared oxygen-reducing insecticide curing agent is packed in a small package with fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com