Valve air tightness detection system

A technology for air tightness detection and valves, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, etc. The test conditions of the test valves are consistent, the test results are easily affected, etc., to achieve the effect of consistent test conditions, convenient operation, and consistent opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

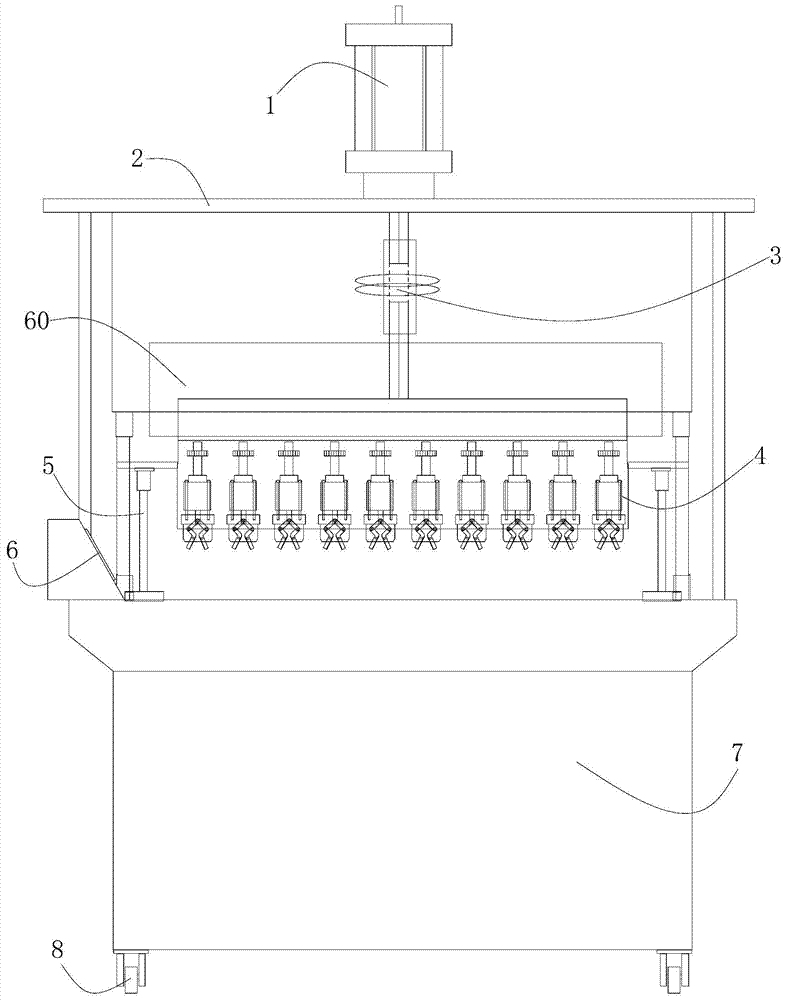

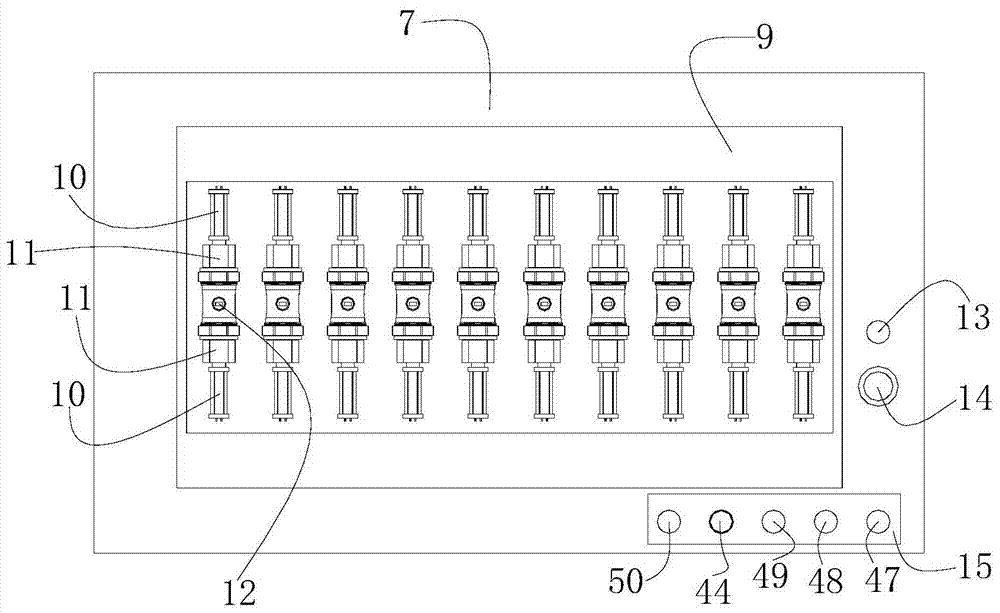

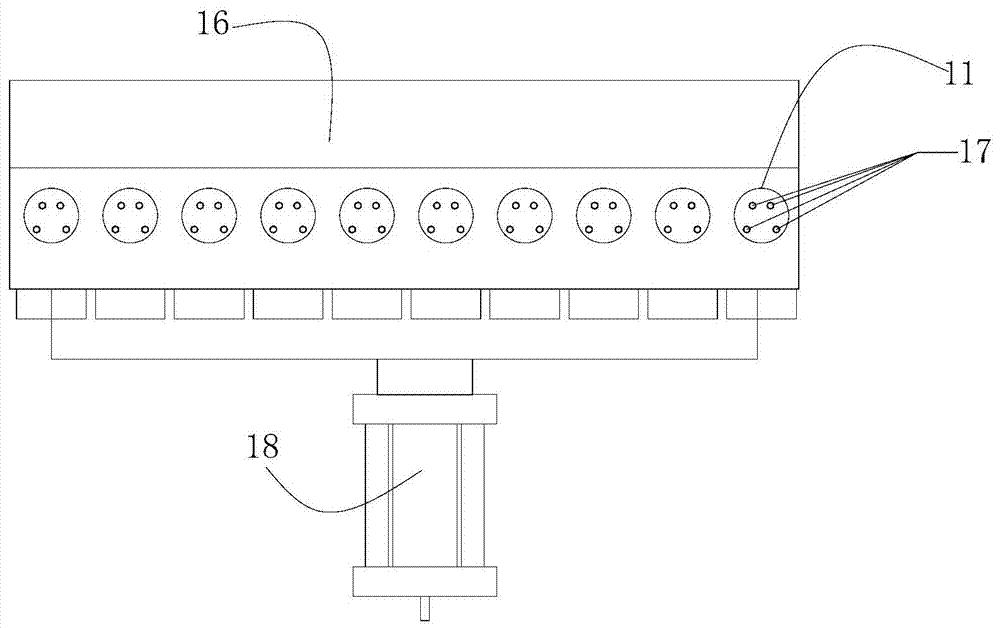

[0026] Such as Figure 1-7 As shown, the valve airtightness detection system of the present invention comprises a water tank 7, a water tank support 2 fixed on the top of the water tank 7, an upper and lower pneumatic cylinder 1 on the water tank support 2, and a piston rod end connected with the upper and lower pneumatic cylinder 1. The manipulator bracket 60, several manipulators 4 arranged on the manipulator support 60 and respectively corresponding to the manipulator 4 above the valve 12 to be tested, and the manipulator transmission mechanism connected with each manipulator 4. The water tank 7 is provided with a water tank 9, a water inlet cylinder 18, and a plurality of valve clamping fixtures 11 that can close the two ends of the flow channel of the valve to be tested 12. A fixture bracket 16 is connected above the water inlet cylinder 18, and a plurality of valve clamping fixtures 11 are arranged side by side. Set on the fixture bracket 16, the clamping end of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com