Device for measuring friction coefficient of water-lubricated bearing with low speed and heavy load

A water-lubricated bearing and friction coefficient technology, which is applied in the direction of measuring devices, mechanical devices, mechanical bearing testing, etc., can solve the problems that cannot accurately reflect the friction coefficient value of the bearing to be tested, and achieve the effect of realizing accurate measurement and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

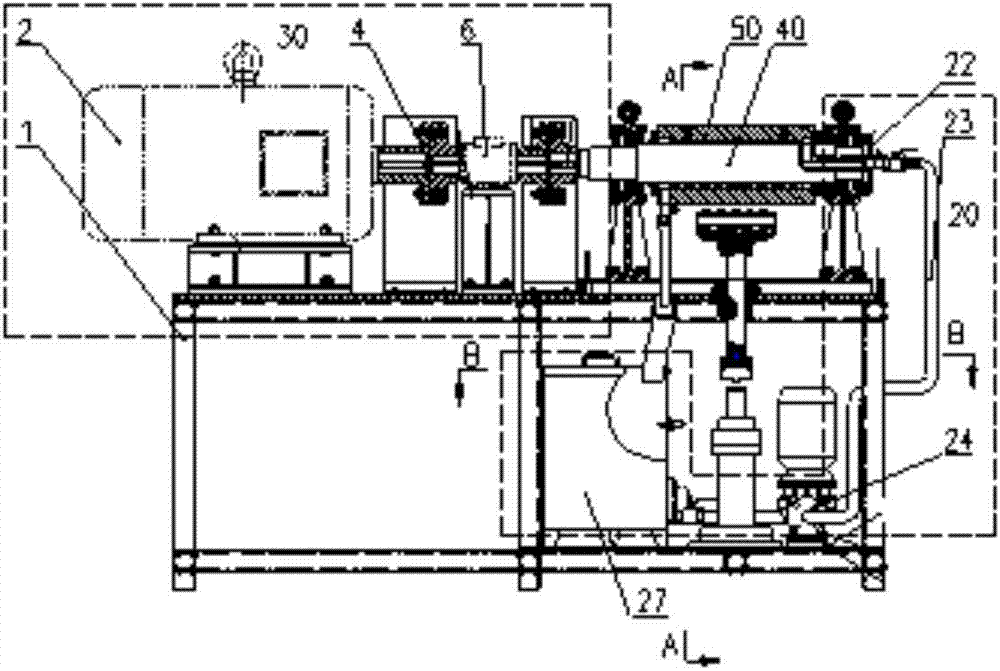

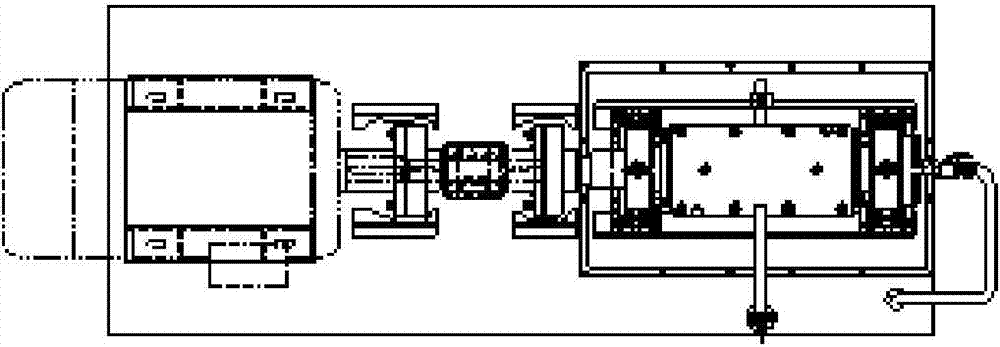

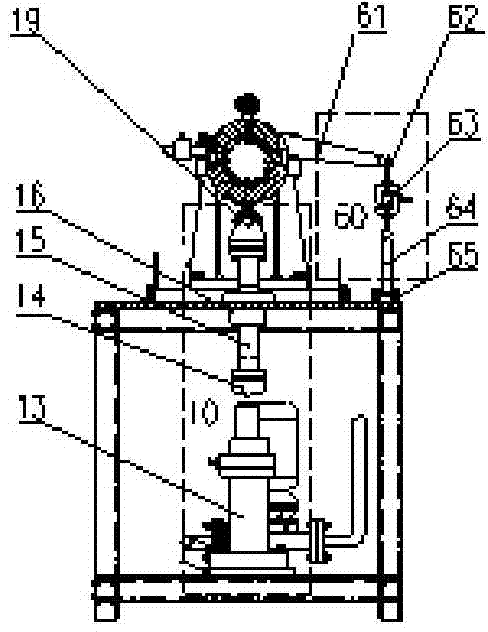

[0031] combine Figure 1-Figure 4 , The water-lubricated bearing friction coefficient measuring device of the present invention mainly includes a bearing load loading mechanism 10, a water circulation and sealing device 20, a motor and a transmission device 30, a shaft 40 and a bearing 50, a friction measuring device 60 and ancillary systems.

[0032]The bearing load loading mechanism 10 is composed of a hydraulic cylinder 13 , a load sensor 14 , a loading rod 15 , a linear bearing 16 and a loading rolling bearing mechanism 19 . The hydraulic cylinder 13 is arranged on the common base, and there are load cell 14, loading rod 15, and rolling bearing mechanism 19 from bottom to top, wherein the horizontal and axial displacement of the loading rod is constrained by the linear bearing 16, and it can only move vertically.

[0033] The water circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com