Automatic detection method for defects of airplane structural-member model

A technology for automatic detection of aircraft structural parts, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

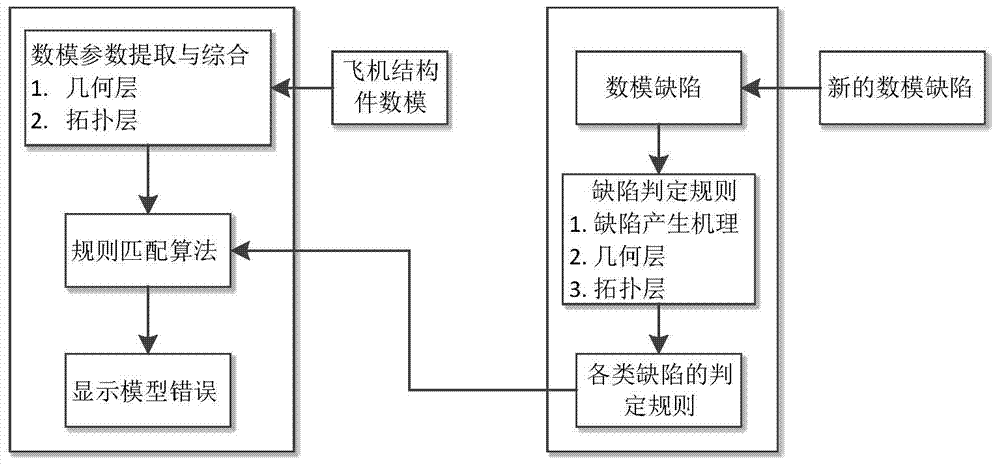

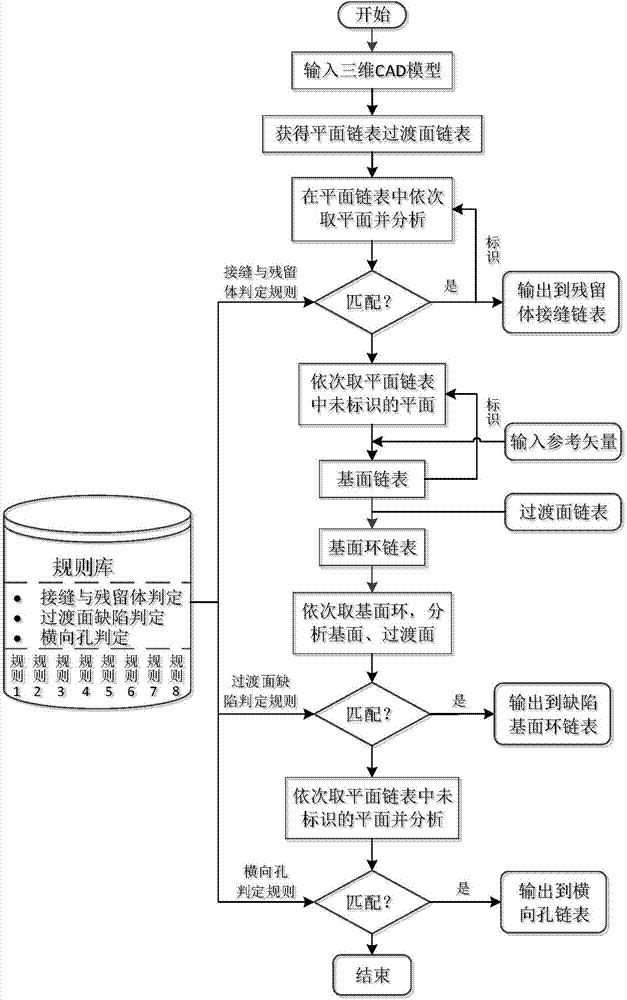

[0057] refer to Figure 1-3 . The specific steps of the automatic detection method for aircraft structural part model defects of the present invention are as follows:

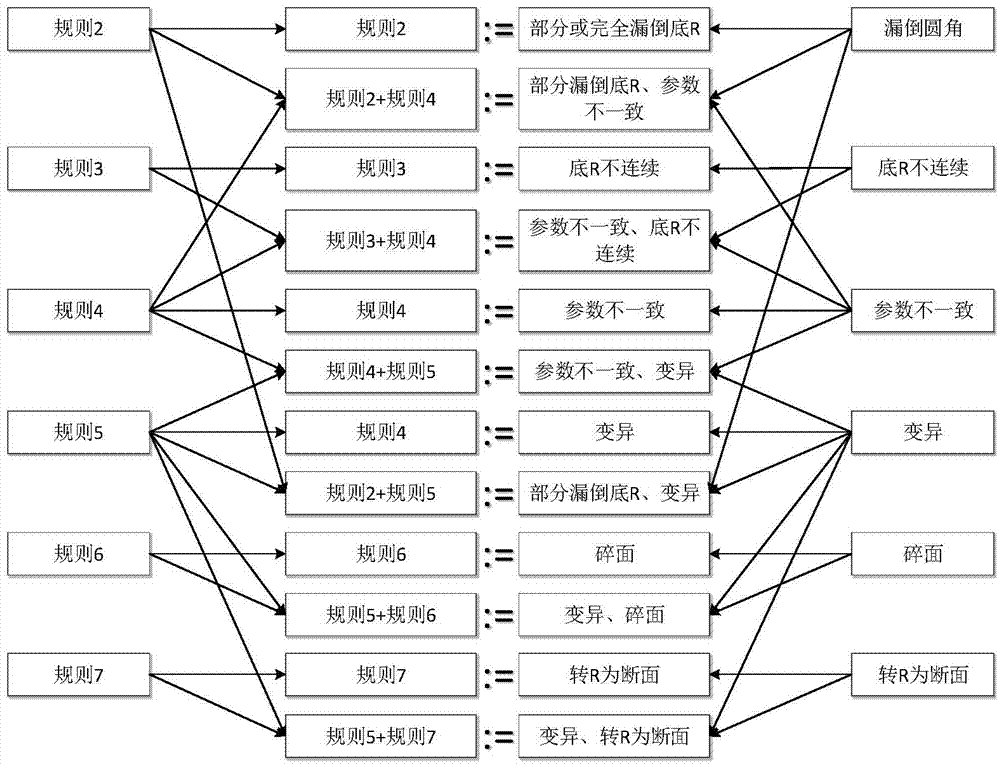

[0058] 1. Defect judgment rule extraction. The mechanism of digital-analog defects and their characteristics at the geometric and topological levels are analyzed, summarized, and the corresponding judgment rules are extracted, and applied to the identification of defects. For the new digital-analog defect, according to its structural characteristics, whether it belongs to the existing defect type, if not, it is necessary to formulate its corresponding judgment rules.

[0059] 2. Extraction and synthesis of digital and analog parameters. For the structural part model to be detected, the geometric parameters and topological properties of the three levels of surface, edge and point are extracted. For faces: include face types (base faces, transition faces, and other types of faces), face areas, face directiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com