An automatic power-off control device and control method for electric locomotive stringing

A technology of automatic power-off and control devices, applied in computer control, program control, general control systems, etc., can solve problems such as electric shock casualties, failure to improve personal safety, long power transmission delay, etc., to ensure rail transportation and personal safety , reduce the effect of rear-end collision personnel electric shock, leakage and stray current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment, further illustrate the present invention.

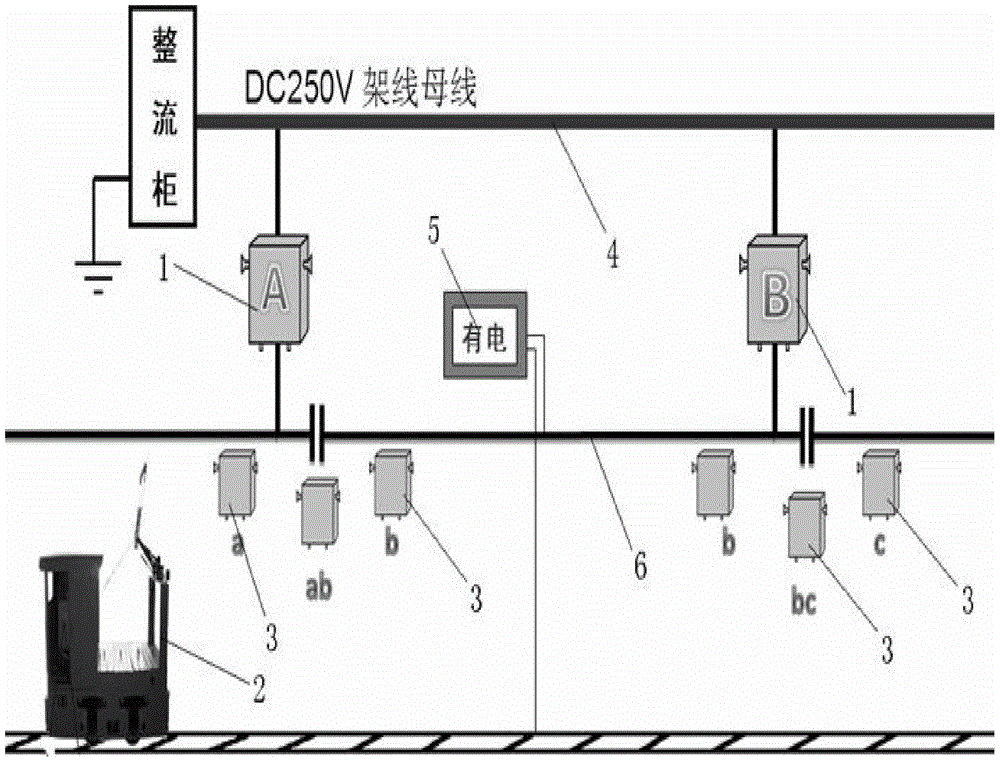

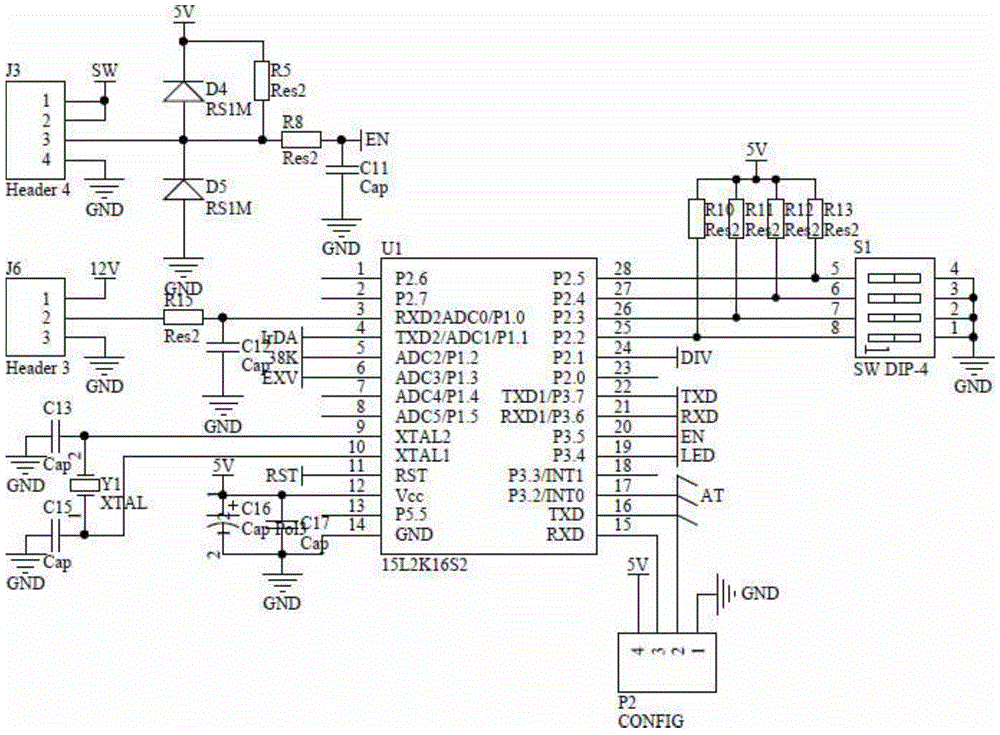

[0036] see Figure 1-Figure 4 , the present invention includes a control host 1, an electric locomotive vehicle-mounted machine and a roadway wall-mounted positioning machine 3.

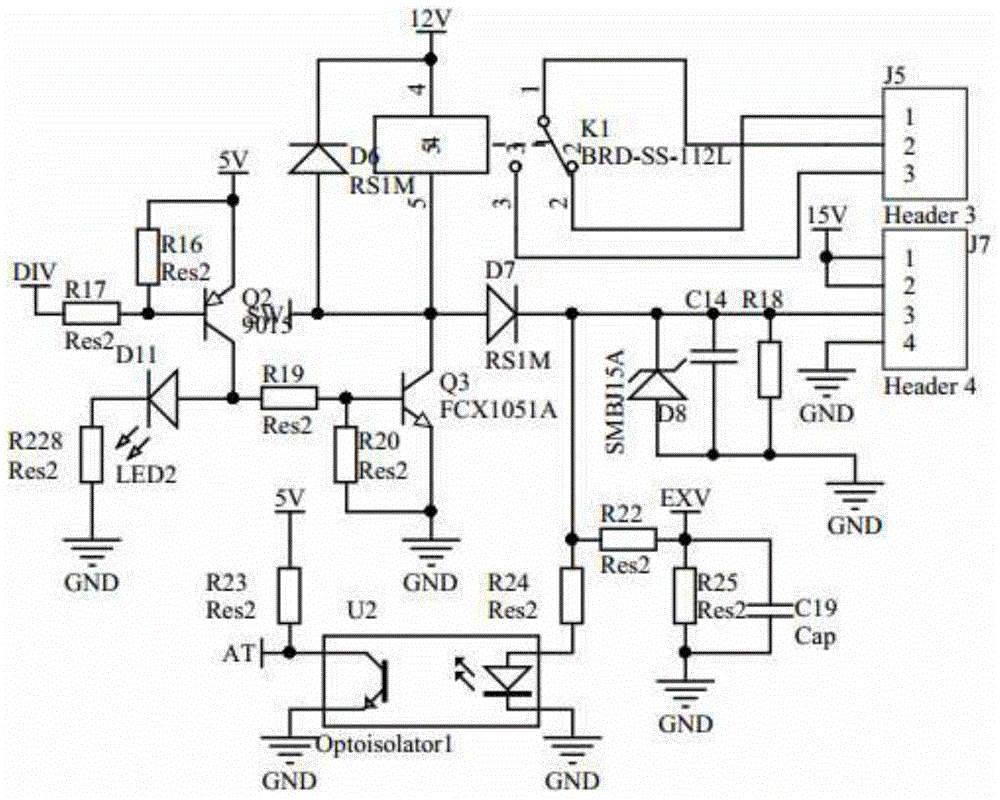

[0037] Control host: receive the carrier signal transmitted by the corresponding wiring, complete address resolution, if the resolved address matches, connect the DC bus and the wiring of this section, and detect the working status of the electric locomotive to cut off the power in real time;

[0038] On-board machine for electric locomotive: The on-board MCU of the on-board machine for electric locomotive pre-stores an address of the roadway wall-mounted positioning machine. When the on-board machine for electric locomotive is activated, it will detect the address update. If the address is updated, store the updated address and The address is sent to the control host. If the address is not updated, the data inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com