System and method for data acquisition and playback in industrial production process

A technology for data acquisition and industrial production, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve the problems that historical data simulation, analysis and optimization cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

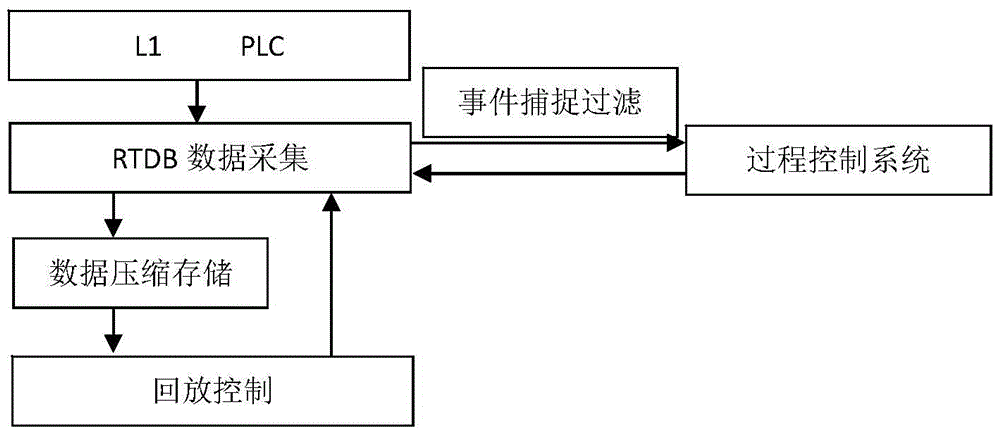

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the system and method will be described in detail below taking the continuous casting process control system as an example and referring to the accompanying drawings.

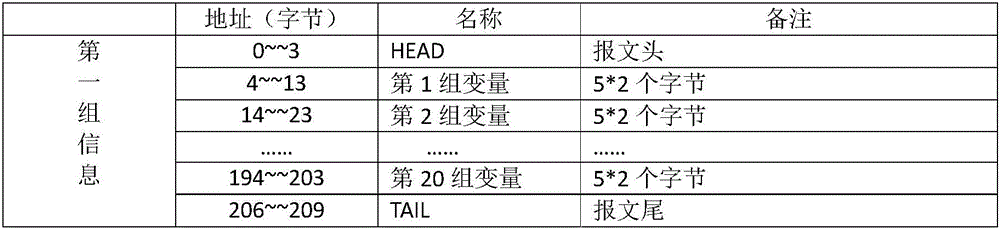

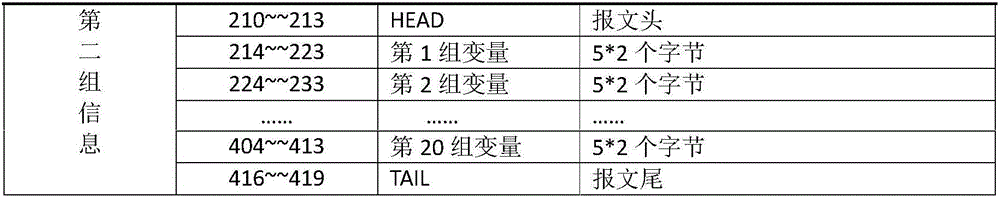

[0035] In the continuous casting process control system, it generally takes 8‐10 hours for a casting from start to finish. In the continuous casting process, the crystallizer is an important equipment in the continuous casting process. During the debugging stage, the fastest acquisition of crystallizer vibration data can reach 10ms. There are about 2,000 conventional data collection points, including data such as data related to large ladle tundish, water flow information of primary cooling and secondary cooling, and casting speed. Through the system and method, online data collection, storage compression and offline operation of the control system, offline acceleration of data, and single-frame playback mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com