Iterative repair method for holes of false tooth triangular mesh model

A triangular grid and hole technology, applied in the field of denture restoration, can solve problems such as stress concentration of denture restorations, loss of feature information, and influence of tooth restoration process, and achieve the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

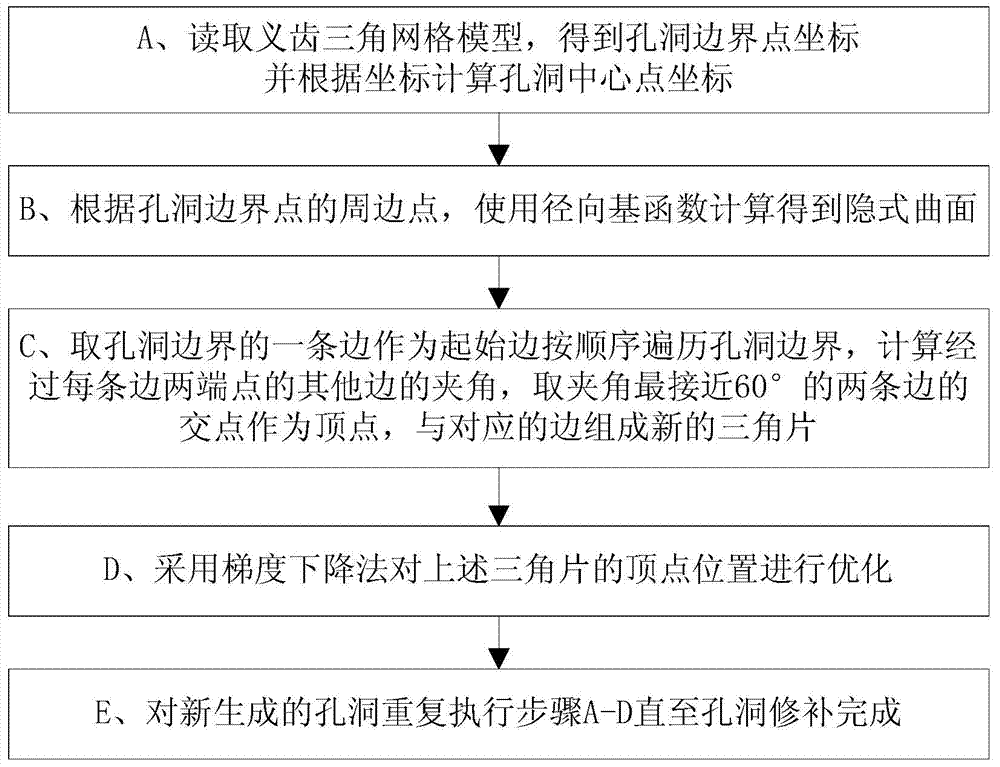

[0043] refer to figure 1 , a method for iteratively repairing holes in a denture triangular mesh model, comprising the following steps:

[0044] A. Read the triangular mesh model of the denture, obtain the coordinates of the boundary points of the hole, and calculate the coordinates of the center point of the hole according to the coordinates;

[0045] The hole is formed due to the lack of data in the triangular mesh model obtained by scanning the teeth due to the partial occlusion of the part or the limitation of the measurement means.

[0046] B. According to the peripheral points of the boundary points of the hole, the implicit surface is calculated by using the radial basis function;

[0047] C. Take one side of the hole boundary as the starting side to traverse the hole boundary in order, calculate the angle between the other sides passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com