Continuous box girder adopting corrugated steel web steel structure

A corrugated steel web and steel structure technology, applied in truss structures, joists, girders, etc., can solve the problems of short service life of box girder, poor shear and buckling resistance, and stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

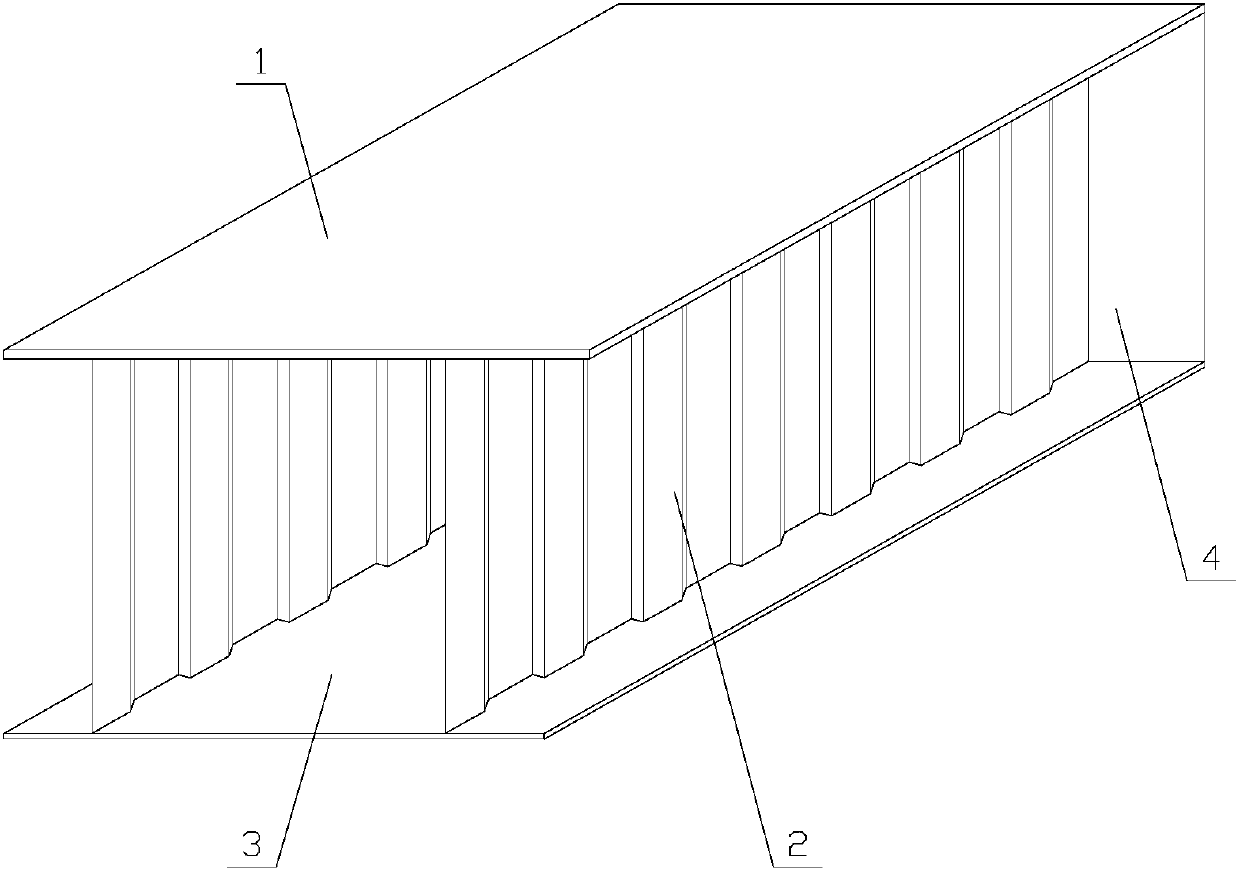

[0028] Corrugated steel web steel continuous box girder, such as Figure 1 to Figure 6 As shown, it includes two corrugated steel webs 2, a top steel plate 1, a bottom steel plate 3, and a connecting end. The corrugated steel web 2 is arranged between the top steel plate 1 and the bottom steel plate 3, and the top steel plate 1 and the corrugated steel web The plate 2 is connected by welding, the corrugated steel web 2 and the bottom steel plate 3 are connected by welding, and the individual beam structures are connected by connecting ends to form a continuous beam structure.

[0029] The surface roughness of the top steel plate and the bottom steel plate is 70-350 μm. Increase the surface roughness of the top steel plate 1 and the bottom steel plate 3, high roughness can significantly increase the adhesion of the coating.

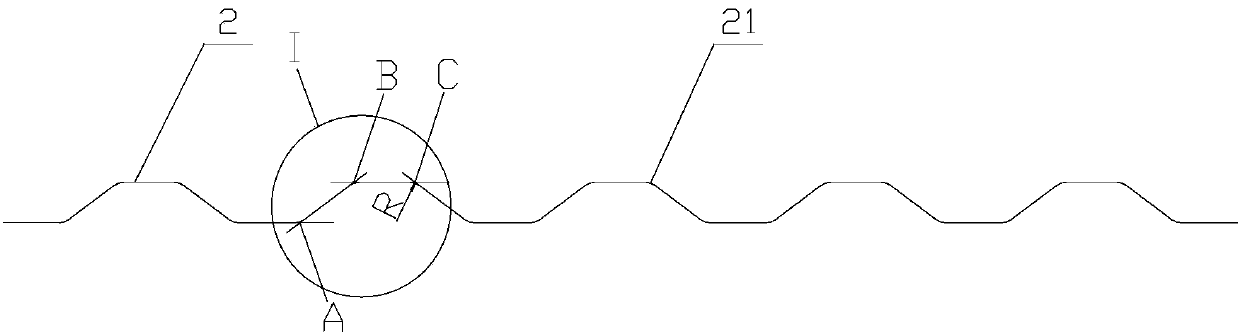

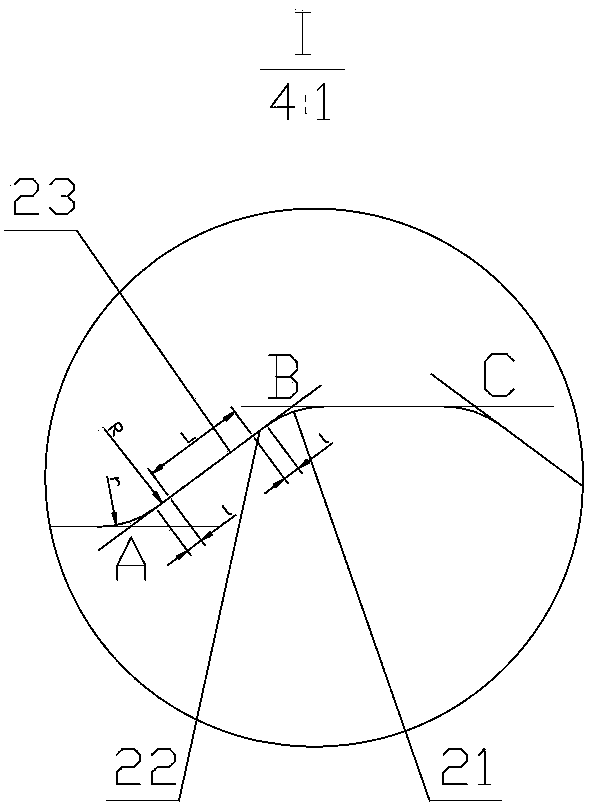

[0030] The corrugated steel web is a continuous trapezoidal corrugated steel plate with a transition section and an arc corner. The transition section is...

Embodiment 2

[0038] Such as Figure 1 to Figure 5 , 7, the difference between this embodiment and embodiment 1 is that the single beam structures are connected by steel cables 5 to form a continuous beam structure. The compression area of the connection end is a plug-in structure. The plug-in structure is that one end of the connection end of the box girder is provided with a plug 24, and the other end is provided with a jack 25. The adjacent simply supported box girders are connected through the plug 24 and the jack 25. . Through the cooperation of the plug 24 and the socket 25, the plug-in pressure-bearing structure of the pressure-receiving area can not only make the connection stable, but also have shrinkage space when the temperature changes. While the connection of the tension area is stable, the setting of its cavity can resist the phenomenon of thermal expansion and contraction when the temperature of the beam body changes.

[0039] The plug 24 is provided with a barb, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com