A kind of preparation method of lead-acid battery pole plate corrosion layer mounting sample

A lead-acid battery and a manufacturing method of the technology are applied in the directions of lead-acid battery electrodes, electrode carriers/current collectors, etc., and can solve the problems of shedding of active substances, harm to lead personnel and the environment, damage to the structure of the corrosion layer of the electrode plate, and the like. Simple, easy-to-organize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of lead-acid storage battery electrode plate corrosion layer mount sample preparation method, carry out according to the following steps:

[0027] a. Plate preparation: dissect a 6-DZM-12 battery, take out a piece of undamaged positive plate, no short circuit can occur in the dissection process, immediately rinse the positive plate with distilled water to remove sulfuric acid until the filtered water becomes until neutral, then immediately put the positive plate into a vacuum drying oven to dry at 60°C for 24h.

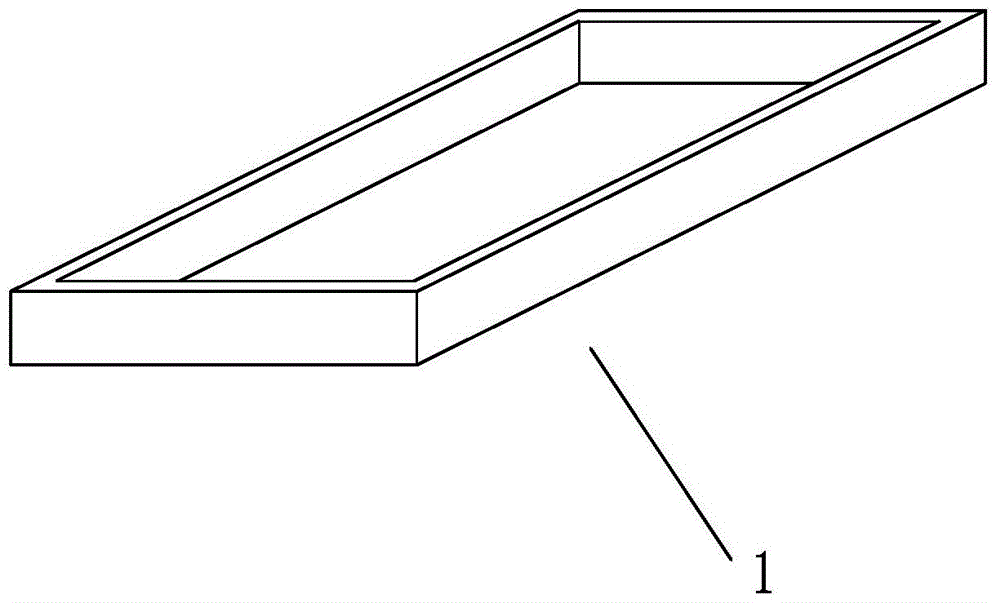

[0028] b. Preparation of mounting mold: as figure 1 As shown, according to the size of the positive plate, a rectangular tray-shaped mold 1 that can be placed in the positive plate is prepared with plexiglass. The length, width, and height of the tray-shaped mold cavity are all 6mm larger than the corresponding size of the positive plate. The thickness of the mold is 3mm, and the demoulding angle of the mold is 3 degrees.

[0029] c. Preparation of epo...

Embodiment 2

[0034]A kind of lead-acid storage battery electrode plate corrosion layer mount sample preparation method, carry out according to the following steps:

[0035] a. Plate preparation: Dissect a 6-DZM-12 battery, take out a negative plate without damage, no short circuit can occur during the dissection process, immediately rinse the negative plate with distilled water to remove sulfuric acid until the filtered water becomes until neutral, and then immediately put the negative plate into a vacuum drying oven to dry at 60°C for 24h.

[0036] b. Preparation of mounting mold: as figure 1 As shown, according to the size of the negative plate, a rectangular tray-shaped mold 1 that can be put into the negative plate is prepared with polyethylene, and the length, width, and height of the tray-shaped mold cavity are all 6mm larger than the corresponding size of the negative plate. The thickness is 4mm, and the demoulding angle of the mold is 1 degree.

[0037] c. Preparation of epoxy re...

Embodiment 3

[0042] A kind of lead-acid storage battery electrode plate corrosion layer mount sample preparation method, carry out according to the following steps:

[0043] a. Plate preparation: Select a non-damaged positive plate for use.

[0044] b. Preparation of mounting mold: as figure 1 As shown, according to the size of the positive raw plate, a rectangular tray-shaped mold 1 that can be placed in the positive raw plate is prepared with polytetrafluoroethylene, and the length, width and height of the tray-shaped mold cavity are all in proportion to The corresponding size of the positive raw plate is 4mm larger, the thickness of the mold is 2mm, and the demoulding angle of the mold is 5 degrees.

[0045] c. Preparation of epoxy resin mosaic material: first weigh 85g of bisphenol S-type epoxy resin in a beaker with an electronic balance, then add 45g of ethylenediamine to the beaker, and mix evenly to prepare epoxy resin mosaic material for backup.

[0046] d. Mounting for the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com