Litchi can rich in litchi pulp polyphenol QRR and preparation method thereof

A technology for lychee pulp and canned lychee, which is applied in the fields of fruit and vegetable preservation, heating preservation of fruits/vegetables, and preservation of fruits/vegetables through radiation/electrical treatment, etc. Polyphenol QRR damage and other problems, to achieve good antioxidant activity, protection of nutritional value, tissue shape and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

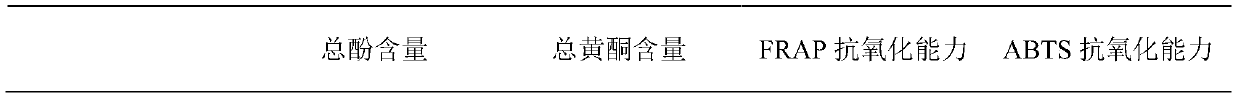

[0032] The canned food rich in lychee pulp polyphenol QRR is composed of the following raw materials by weight: 50 parts of lychee pulp, 24 parts of sodium citrate, 4 parts of disodium hydrogen phosphate, 13 parts of sucrose, 4 parts of vitamin C, carboxymethyl cellulose (CMC) 3 parts, a total of 0.3 parts of composite starch octyl succinate and sodium alginate, wherein the ratio of composite starch octyl succinate and sodium alginate is 1:1.

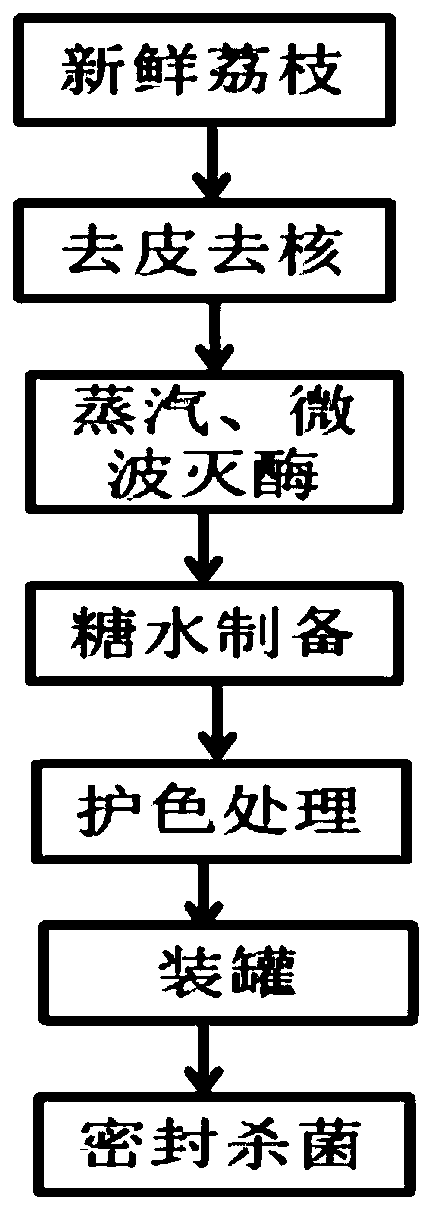

[0033] The preparation method includes the following steps:

[0034] S1. Choose fresh lychees and clean them, peel them, dig the core, wash the lychee pulp and soak in clean water for 30 minutes;

[0035] S2. High temperature and humid steam, microwave inactivation of enzymes: spread the lychee pulp in step S1 evenly on the dish, and first subject the lychee pulp to 110-130°C high-temperature humid-heat steam treatment for 20-30s and then 800W microwave treatment for 0.8-1.2min ;

[0036] S3. Preparation of aqueous sugar solution: 0.1mol·L -1 ...

Embodiment 2

[0041] The canned food rich in lychee pulp polyphenol QRR is composed of the following raw materials: 40 parts of lychee pulp, 25 parts of sodium citrate, 5 parts of disodium hydrogen phosphate, 12 parts of sucrose, 5 parts of vitamin C, 5 parts of CMC, compound A total of 0.2 parts of starch octyl succinate and sodium alginate, in which the ratio of composite starch octyl succinate and sodium alginate is 6:4.

[0042] The preparation method includes the following steps:

[0043] S1. Choose fresh lychees and clean them, peel them, dig the core, wash the lychee pulp and soak in clean water for 30 minutes;

[0044] S2. High temperature and humid steam, microwave inactivation of enzymes: spread the lychee pulp in step S1 evenly on the dish, and first subject the lychee pulp to 110-130°C high-temperature humid-heat steam treatment for 20-30s and then 800W microwave treatment for 0.8-1.2min ;

[0045] S3. Preparation of aqueous sugar solution: 0.1mol·L -1 Sodium citrate solution and 0.2mo...

Embodiment 3

[0050] The canned food rich in lychee pulp polyphenol QRR is composed of the following raw materials: 60 parts of lychee pulp, 23 parts of sodium citrate, 3 parts of disodium hydrogen phosphate, 15 parts of sucrose, 2 parts of vitamin C, 2 parts of CMC, compound A total of 0.5 parts of starch octyl succinate and sodium alginate, in which the ratio of composite starch octyl succinate and sodium alginate is 4:6.

[0051] The preparation method includes the following steps:

[0052] S1. Choose fresh lychees and clean them, peel them, dig the core, wash the lychee pulp and soak in clean water for 30 minutes;

[0053] S2. High temperature and humid steam, microwave inactivation of enzymes: spread the lychee pulp in step S1 evenly on the dish, and first subject the lychee pulp to 110-130°C high-temperature humid-heat steam treatment for 20-30s and then 800W microwave treatment for 0.8-1.2min ;

[0054] S3. Preparation of aqueous sugar solution: 0.1mol·L -1 Sodium citrate solution and 0.2mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com