Ferroelectric film alternating electric field heat treatment method

A heat treatment method and ferroelectric thin film technology, applied in the field of heat treatment technology, can solve the problem of high material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

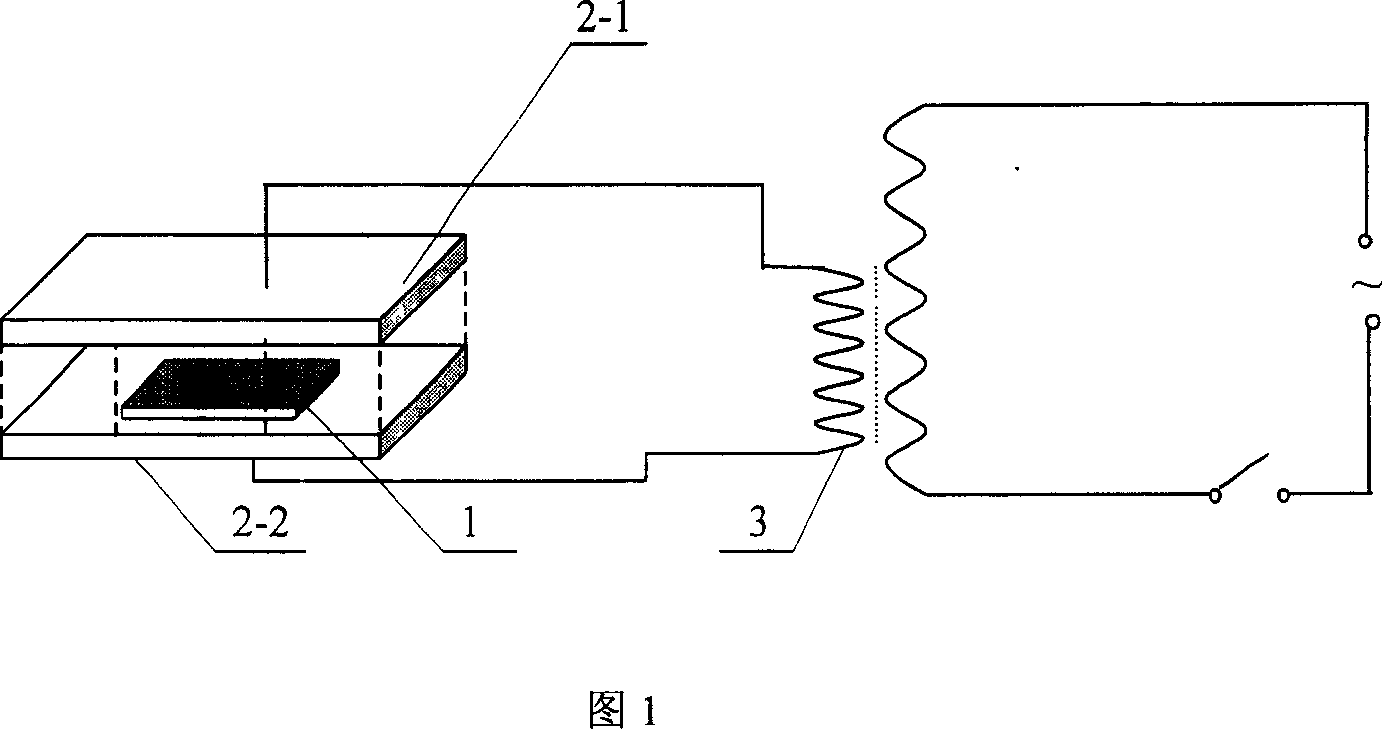

[0008] Specific embodiment one: as shown in Figure 1, this specific embodiment is carried out according to the following steps: One, in Pt / Ti / SiO 2 Deposit ferroelectric thin film material on / Si substrate, and carry out high-temperature annealing crystallization, form ferroelectric thin film 1; 2, carry out secondary annealing to described ferroelectric thin film 1, and introduce alternating electric field in described secondary annealing process, The action direction of the alternating electric field is perpendicular to the film surface of the ferroelectric thin film 1, and the film surface of the ferroelectric thin film 1 faces upward and is kept isolated from the upper plate 2-1 of the alternating electric field generator. The purpose of keeping the film surface of the ferroelectric thin film 1 in an isolated state from the upper plate 2-1 is to avoid the clamping effect.

specific Embodiment approach 2

[0009] Specific embodiment two: as shown in Figure 1, in specific embodiment one, the generating device of described alternating electric field is made up of adjustable transformer 3, upper polar plate 2-1 and lower polar plate 2-2, and mains power One end is connected to the input end of the upper pole plate 2-1 through the adjustable transformer 3, and the other end of the mains is connected to the input end of the lower pole plate 2-2 through the adjustable transformer 3, and the upper pole plate 2-1 and the lower pole plate 2-2 are two conductive metal electrodes insulated from each other. Fix the distance between the upper pole plate 2-1 and the lower pole plate 2-2, then change the voltage applied between the upper pole plate 2-1 and the lower pole plate 2-2 by adjusting the output voltage of the adjustable transformer 3, The alternating electric field is thereby obtained. Using this method to obtain the required alternating electric field is simple, convenient and low ...

specific Embodiment approach 3

[0010] Embodiment 3: In Embodiment 1, the Curie point of the ferroelectric thin film material is in the range of 300°C to 800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com