Preparation process of residue-free hotpot condiment

A technology of hot pot bottom material and preparation process, which is applied in food ingredients containing natural extracts, food ingredients as emulsifiers, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

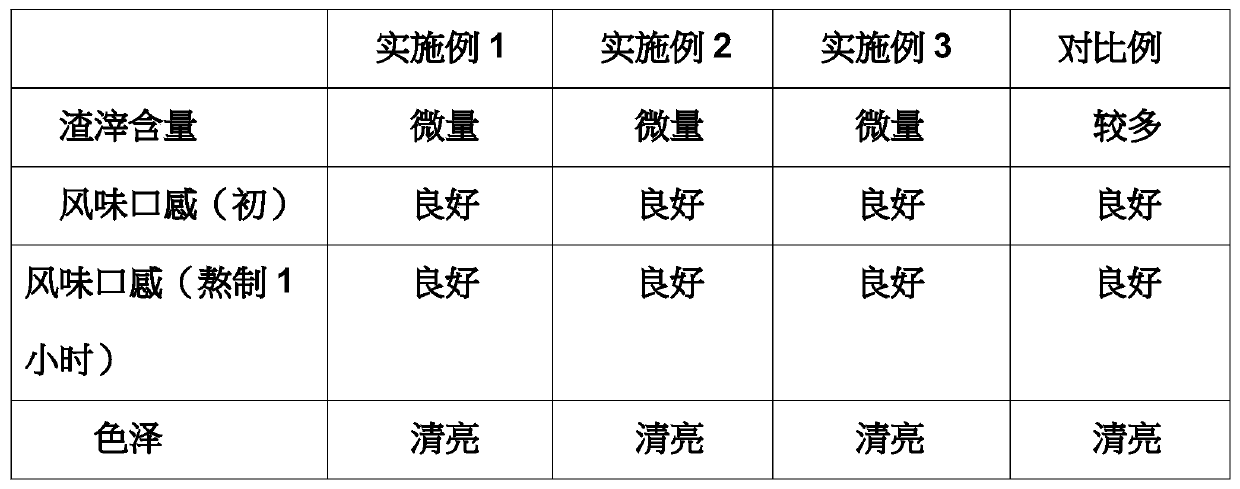

Examples

Embodiment 1

[0024] A. According to the ratio of 1:1, select 30 parts of baby's breath pepper and chaotian pepper pepper, soak in cold water for 0.5 hours, then remove and dry for later use;

[0025] B. Weigh 10 parts of spices, said spices include sweet song 1, clove 1, star anise 2, cumin 1, grass fruit 1, Amomum 1, Sannai 1, Lingcao 1, Paicao 3, Baicao 1 in parts by weight. Cardamom 1, nutmeg 1, cinnamon bark 2, and bay leaf 1, break the spices into pieces, put them in warm water at 15°C and soak for 15 minutes, then put them together with warm water in a steamer for 30 minutes on high heat , according to parts by weight, the proportioning ratio of spices and warm water is 5:1;

[0026] C. Heat the frying pan to 70°C, take butter and add it to the frying pan to melt, when it is melted and heated to 90°C, add 5 parts of the first auxiliary material, refine for 15 minutes, remove the first auxiliary material; heat to 100 After ℃, add the treated pepper and fry for 30 minutes, then add th...

Embodiment 2

[0033] A. According to the ratio of 1:1, select 40 parts of baby's breath pepper and chaotian pepper pepper, soak in cold water for 2 hours, then remove and dry for later use;

[0034] B. Weigh 12 parts of spices, said spices include sweet song 1, clove 1, star anise 2, cumin 1, grass fruit 1, Amomum 1, three Nye 1, Lingcao 1, Paicao 3, Baicao 1 in parts by weight. Cardamom 1, nutmeg 1, cinnamon bark 2, and bay leaf 1, break the spices into pieces, put them in warm water at 17°C and soak for 20 minutes, then put them in a steamer with warm water and cook for 40 minutes on high heat , according to parts by weight, the proportioning ratio of spices and warm water is 5:1;

[0035] C. Heat the frying pan to 75°C, take butter and add it to the frying pan to melt, when it is melted and heated to 90°C, add 7 parts of the first auxiliary material, refine for 18 minutes, remove the first auxiliary material; heat to 110 After ℃, add the treated pepper and fry for 40 minutes, then add t...

Embodiment 3

[0042] A. According to the ratio of 1:1, select 45 parts of Gypsophila pepper and Chaotian pepper pepper, soak in cold water for 3 hours, then remove and dry for later use;

[0043] B. Weigh 15 parts of spices, said spices include sweet song 1, clove 1, star anise 2, cumin 1, grass fruit 1, Amomum 1, Sannai 1, Lingcao 1, Paicao 3, Baicao 1 in parts by weight Cardamom 1, nutmeg 1, cinnamon bark 2, and bay leaves 1, break the spices into pieces, put them in warm water at 19°C for 30 minutes, put them together with warm water in a steamer and cook for 45 minutes on high heat , according to parts by weight, the proportioning ratio of spices and warm water is 5:1;

[0044]C. Heat the frying pan to 80°C, take butter and add it to the frying pan to melt, when it is melted and heated to 90°C, add 8 parts of the first auxiliary material, refine for 20 minutes, remove the first auxiliary material; heat to 120 After ℃, add the treated pepper and fry for 45 minutes, then add spices and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com