Anti-corrosion treatment method for low-alloy steel pipes of ship boiler

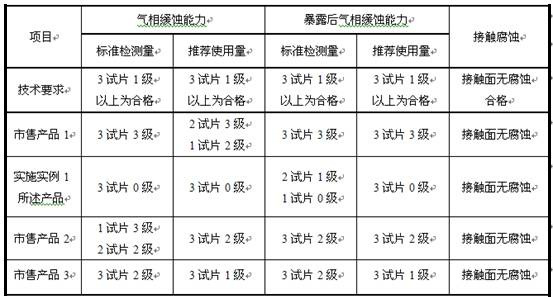

A technology of anti-corrosion treatment and alloy steel pipe, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as complex process steps, corrosion, and affecting the surface quality of final products, so as to improve surface quality and yield, and the operation method is simple and easy Good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

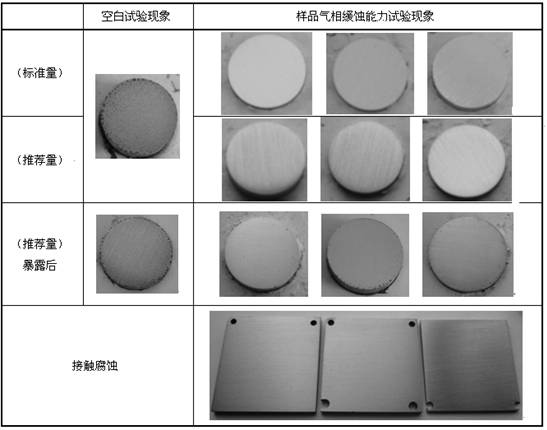

Embodiment 1

[0031] A method for anticorrosion treatment of low-alloy steel pipes for naval boilers, the method comprising the steps of:

[0032] (1) Protection of raw material steel pipes: After the raw material steel pipes are produced, place a desiccant and gas-phase anti-rust film for sealed packaging. Layer structure, thickness: 0.10~0.15mm;

[0033] (2) Heat treatment protection: heat-treat the steel pipe under the protection of argon gas with a certain purity, the purity of the argon gas is ≥99.99%, and the flow rate is 1~3L / min; to ensure that the steel pipe does not produce oxidation that affects the anti-corrosion effect after heat treatment Floor;

[0034] (3) Inter-process protection: After the inside of the steel pipe is purged, a gas-phase anti-rust agent is placed at both ends, and the pipe plug is covered. The shape of the gas-phase anti-rust agent is pill-shaped, and the material of the pipe plug is elastic polyvinyl chloride rubber. , and an anti-collision pipe cap is p...

Embodiment 2

[0041] According to the anti-corrosion treatment method of the low-alloy steel pipe of the ship boiler described in Example 1, the composition and weight ratio of the hydraulic anti-rust agent in the step (4) are: 25-35% modified aliphatic tricarboxylic acid triethanolamine , 5~10% sodium dodecylbenzenesulfonate, 15~20% diazocyclopentenyl imidazolium ammonium salt, 45~60% deionized water.

Embodiment 3

[0043] According to the anti-corrosion treatment method for the low-alloy steel pipe of the ship boiler described in Example 1, the composition and weight ratio of the vapor phase anti-rust agent in the step (3) are: 20-25% nitrosodicyclohexylamine, 15~20% salicylic acid diethylamine sodium salt, 5~10% 1,3 m-nitrobenzoic acid, 2~5% methyl benzotriazole, 4~8% urea, 5~10% hexamethasone Methyltetramine, 30~40% bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com