Anti-corrosion protection device for base material of iron tower

A technology of protection device and iron tower base, applied in towers, building insulation materials, building components, etc., can solve the problems of coating peeling, anti-corrosion cost increase, low protection point, etc., to extend service life and enhance clamping force , The effect of reducing the cost of anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

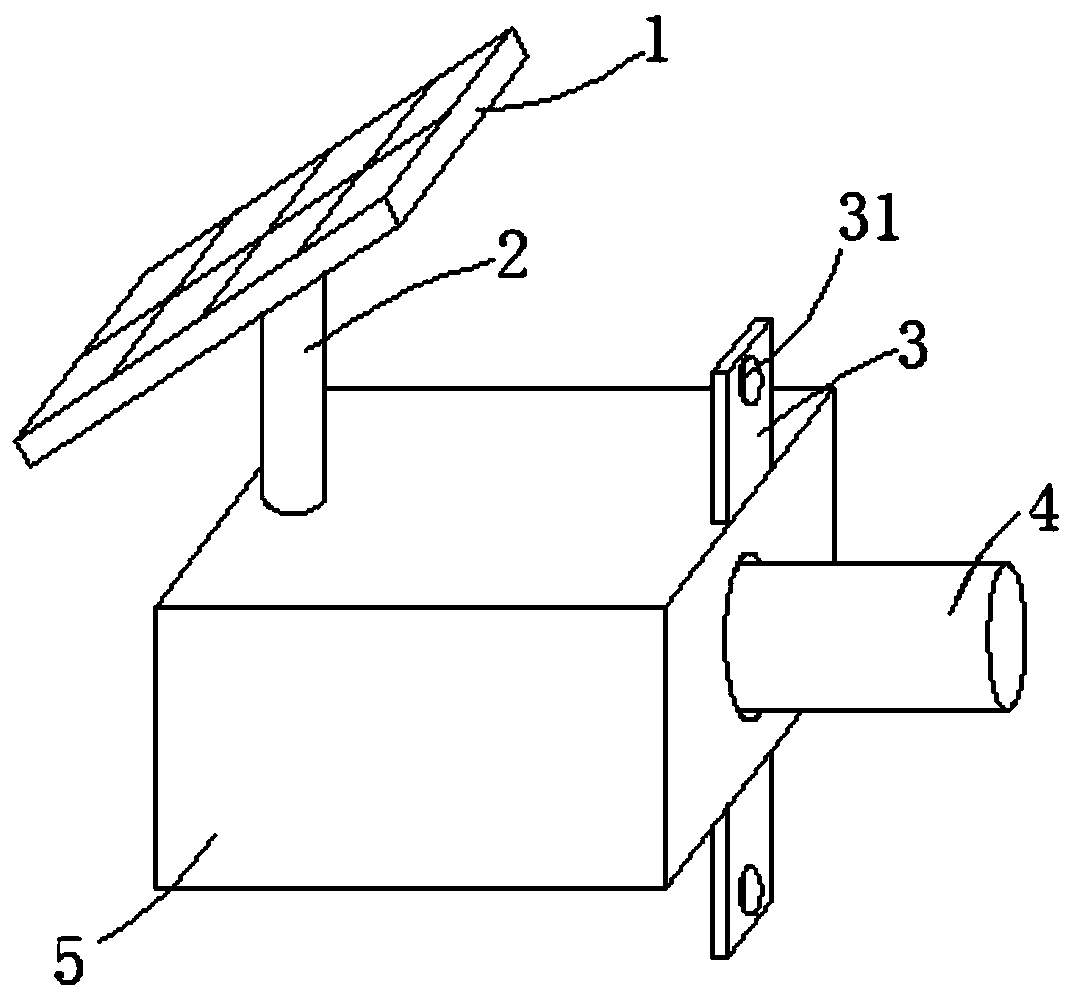

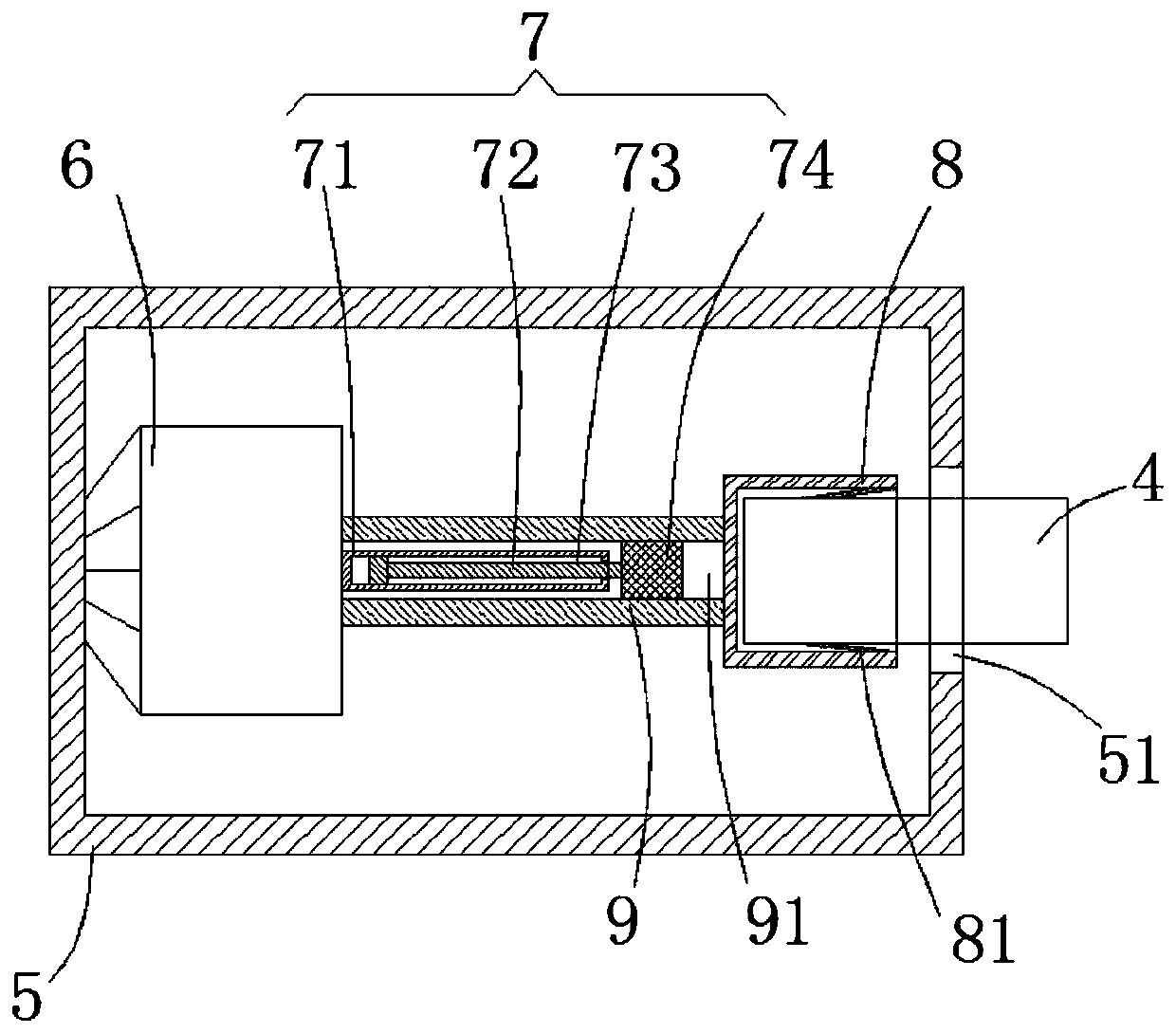

[0020] see Figure 1-3 , the present embodiment provides an anticorrosion protection device for iron tower substrates, including a protective box 5, a transmission mechanism 7 and a data processing module 10, the protective box 5 is a rectangular hollow structure, and the center of the right end face is provided with a hole communicating with the inner cavity Through hole 51, servo motor 6 is fixedly installed on the left central end surface of the inner cavity of protective box 5, and transmission mechanism 7 includes a transmission sleeve 71. The right end of servo motor 6 is connected with transmission sleeve 71 through a power shaft, and transmission sleeve 71 The right end face of the inner cavity is provided with a rectangular drawing groove 73 with a side structure of the inner cavity, and the transmission sleeve 71 is slidably inserted into a rectangular transmission rod 72 through the drawing groove 73, and the tip of the rectangular transmission rod 72 is fixedly weld...

Embodiment 2

[0024] see Figure 1-3 , further improvements have been made on the basis of Example 1:

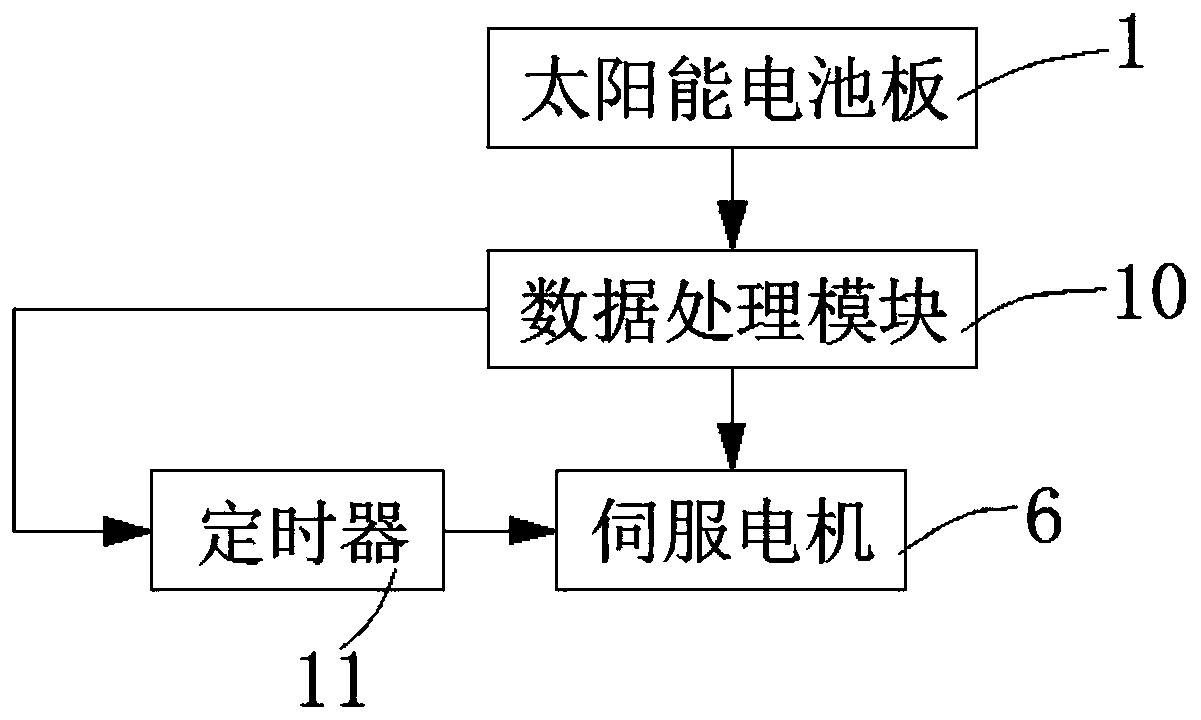

[0025] A support column 2 is welded vertically at the middle position on the left side of the top surface of the protective box 5, and a solar panel 1 is installed on the top surface of the support column 2 inclined at 45 degrees, and the solar panel 1 is connected to the signal input port of the data processing module 10 through wires , powering the data processing module 10 through the solar panel 1 .

[0026] The middle section of the upper and lower sides of the right end surface of the protective box body 5 is vertically welded with an installation backing plate 3, and two installation backing plates 3 are provided with installation holes 31 at one end away from the protective box body 5. The structure is installed at the corner of the iron tower cross arm for anti-corrosion use.

[0027] The outer diameter of the threaded column 74 is equal to 2 times of the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com