Bilayer-structure anticorrosive coating

A technology of double-layer structure and anti-corrosion layer, applied in the direction of pipeline anti-corrosion/anti-rust protection, coating, damage protection, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

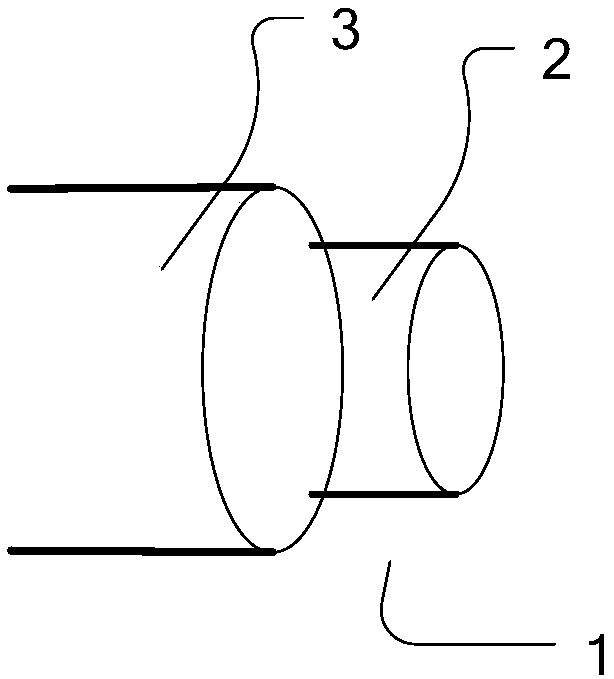

[0009] Such as figure 1 As shown, a kind of double-layer structure anticorrosion layer of the present invention comprises pipeline 1, modified asphalt anticorrosion layer 2 and polyethylene outer coating 3, and described pipeline 1 is modified asphalt anticorrosion layer 2 and polyethylene outer coating respectively from inside to outside. Vinyl exterior coating3. The modified bitumen anti-corrosion layer 2 has sufficient flexibility and can be bent on site. At the same time, it still has the greatest chemical resistance and cathodic disbondment resistance under the condition of thin film thickness, and has good coating film fluidity and solution viscosity. The role of the polyethylene outer coating 3 is to provide good impact resistance, low water permeability and good temperature resistance for the entire coating, in addition, its resistance to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com