Anti-corrosion liner construction method of wet flue gas desulfurization dust removing equipment

A technology of desulfurization and dust removal equipment and construction method, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of poor wear resistance of anti-corrosion linings, poor adaptability to temperature difference changes, etc., and achieves good results and is easy to repair. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

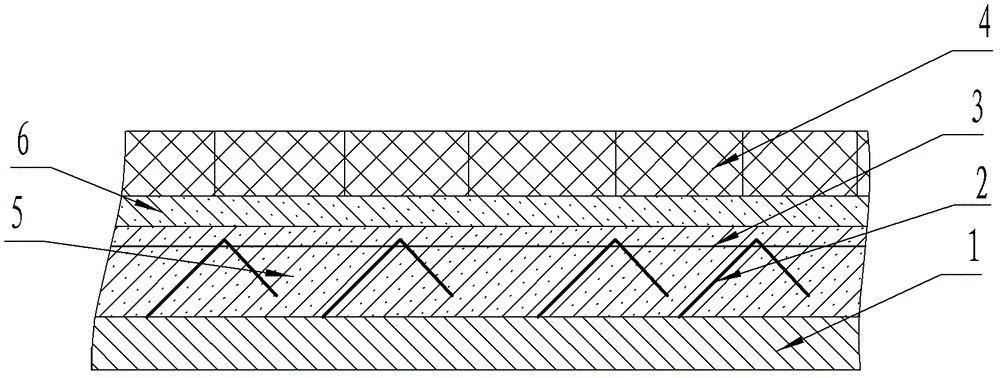

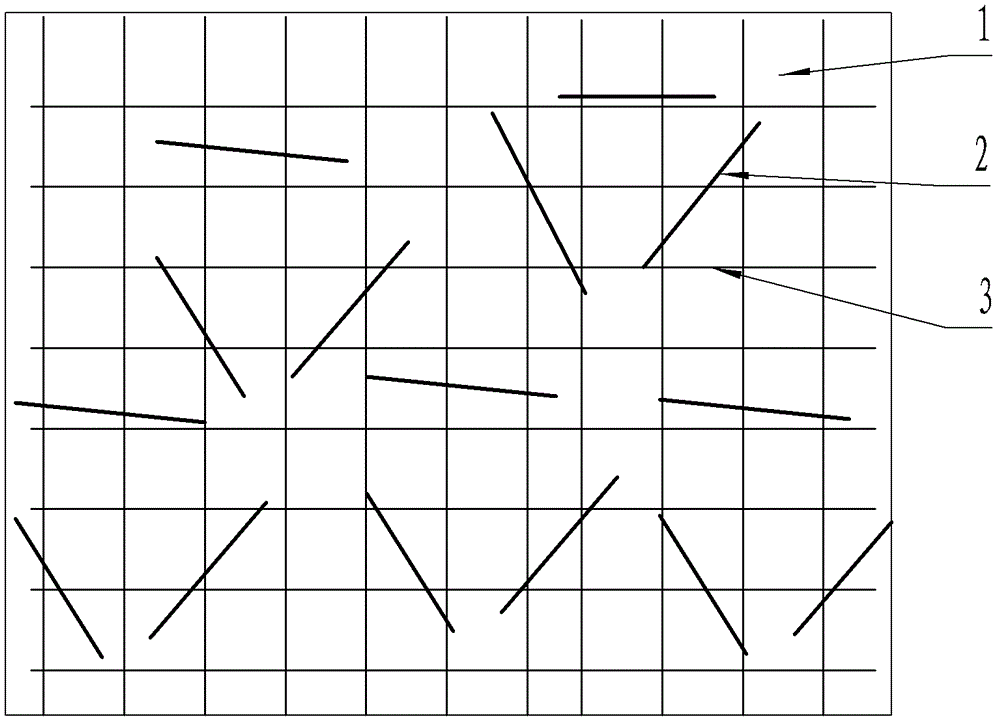

[0015] Embodiment 1, a corrosion-resistant lining for wet flue gas desulfurization and dust removal equipment, is characterized in that it includes a skeleton material, a laying cushion layer 5, an adhesive layer 6, and a surface anti-corrosion layer, and one end of the skeleton material is welded to the equipment shell The inverted V-shaped fixed pile 2 on the body 1 is composed of the steel wire mesh 3 fixed by the inverted V-shaped fixed pile. The laying cushion is an acid-resistant cement layer bonded to the equipment shell and wrapped around the skeleton material. The adhesive layer is a mixed layer of water glass and acid-resistant cement, and the surface anticorrosion layer is an acid-resistant ceramic tile 4 bonded on the adhesive layer. The inverted V-shaped fixed piles are arranged in a triangle on the inner surface of the equipment shell.

Embodiment 2

[0016] Embodiment 2, the construction method of the corrosion-resistant inner lining of wet flue gas desulfurization and dust removal equipment, is characterized in that it includes the following steps:

[0017] A. Install the skeleton material: Clean the dirt and rust on the inner surface of the equipment shell, weld the inverted V-shaped fixed pile, fold the raw material of the fixed pile into an L shape, and weld one end on the equipment shell. The height of the fixed pile column is 15-30mm, and the horizontal The length of the pole is 30-50mm, and the interval between the piles is 150-300mm, which is distributed in an isosceles triangle. The steel wire mesh is set on the fixed pile, and the crossbar of the fixed pile is bent to make it an inverted V shape.

[0018] B. Make the laying cushion, mix with water glass type acid-resistant cement, mix 60% quartz sand as aggregate, after mixing, lay it on the inner wall of the shell that needs anti-corrosion treatment, lay the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com