High pressure-resisting sealing connector and cable manufacturing method

A technology of connectors and connector plugs, which is applied in the direction of connection, two-part connection devices, parts of connection devices, etc., can solve problems such as size restrictions, and achieve the effects of easy repair and maintenance, sealing and pressure bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

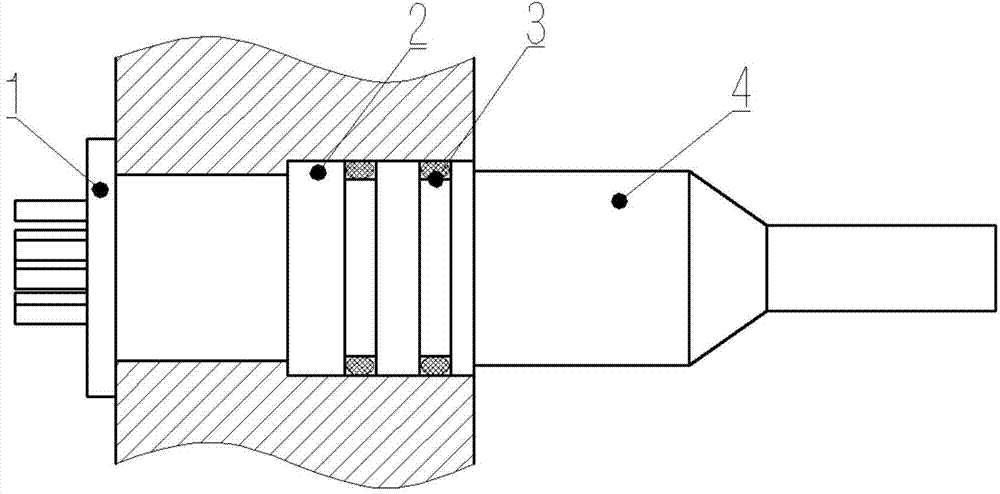

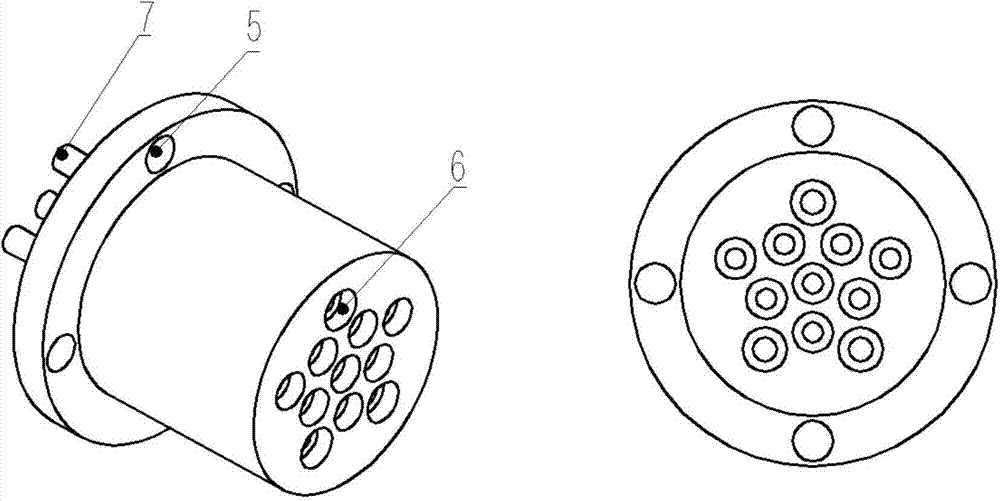

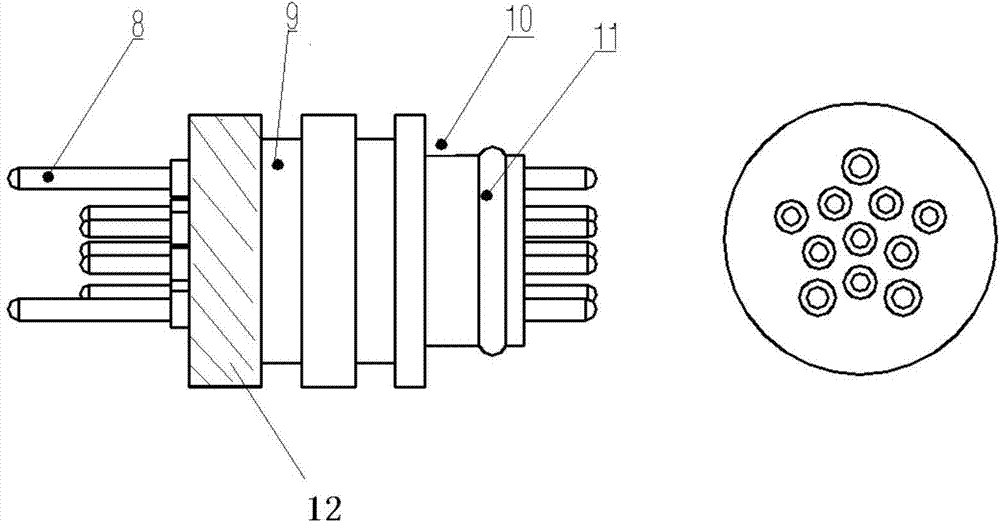

[0041] Such as figure 1 and Figure 4 As shown, the high-voltage resistant sealed connector in the specific embodiment of the present invention is composed of a socket 1, a plug 2, an O-ring 3, a rubber sleeve 4, and a crimp terminal 14 inside the rubber sleeve. Among them, the socket 1 is installed in the sealed cabin; the plug 2 is installed in the sealed cabin and cooperates with the socket; the O-shaped sealing ring 3 is used for sealing the plug 2 in the mounting hole of the bulkhead; the crimping terminal 14 in the rubber sleeve In order to provide connection between the external wire and the plug; the rubber sleeve 4 is the external sealing and safety protection of the plug 2 and the crimping terminal 14 .

[0042] The socket 1 is fixed with the structure of the cabin body with sealing requirements by means of screw fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com