Cross multi-degree-of-freedom ultrasonic motor

An ultrasonic motor, cross-shaped technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It is difficult to reduce the size, which is not conducive to the increase of the thrust of the motor, so as to achieve the effect of small overall size, improved end amplitude and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

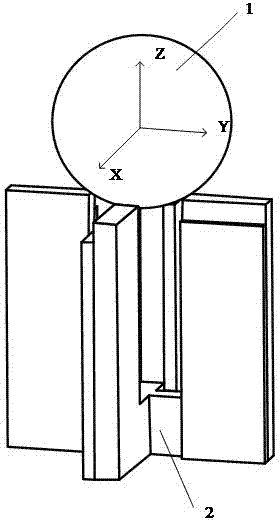

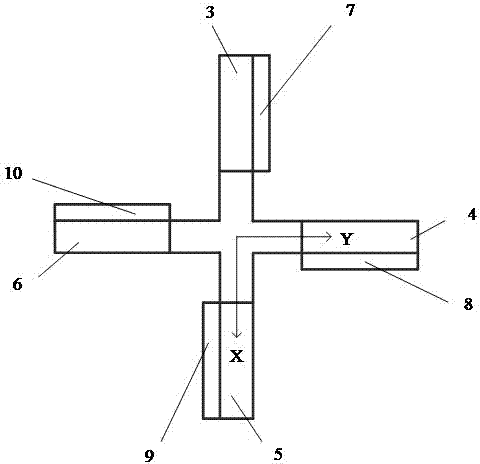

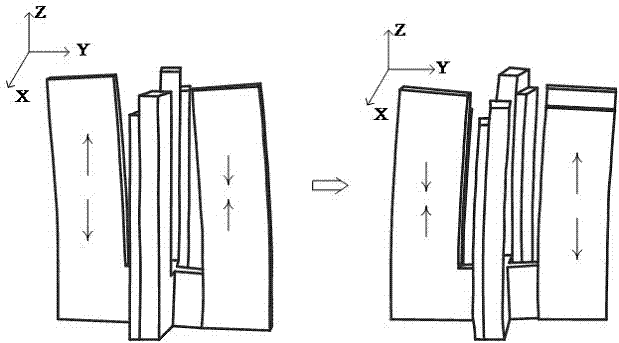

[0028] Such as figure 1 and figure 2 As shown, a cross-shaped multi-degree-of-freedom ultrasonic motor includes a stator 2 and a mover 1, which is characterized in that the mover 1 is a spherical metal body, the overall structure of the stator 2 is cross-shaped, and the center of the stator 2 is square The blind hole divides the stator 2 into the rear drive foot 3, the right drive foot 4, the front drive foot 5, and the left drive foot 6. Four piezoelectric ceramic sheets are asymmetrically attached to the four drive feet of the stator 2. The piezoelectric ceramic The sheet is as wide as the driving foot, and the length is less than the length of the driving foot. The piezoelectric ceramic sheets are respectively connected to the corresponding signal input terminals; The child 1 has a certain contact pressure along the vertical direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com