continuous casting method for steel

A technology of casting speed and cast slabs, which is applied in the field of continuous casting of steel, can solve the problems of unspecified solidified shell thickness, unstable cast slab shape, and unimproved center segregation, so as to improve center segregation, increase reduction efficiency, reduce The effect of center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

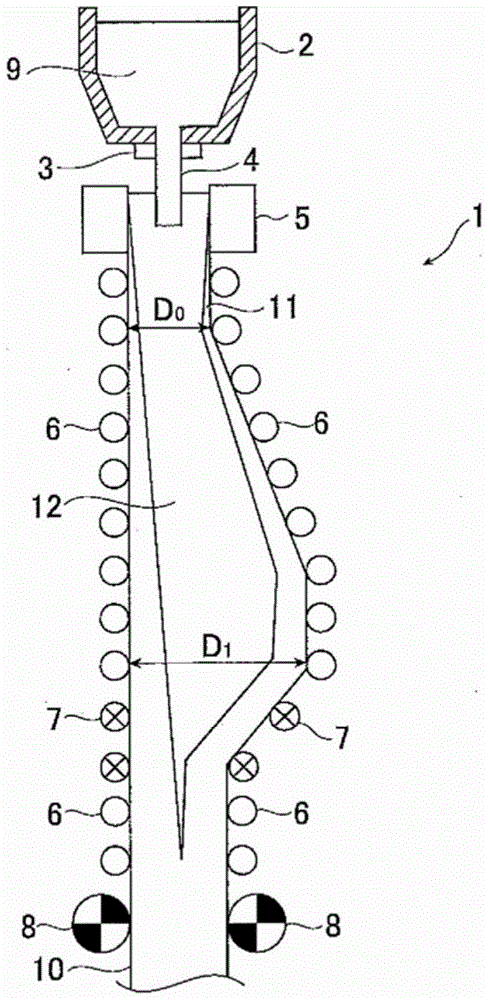

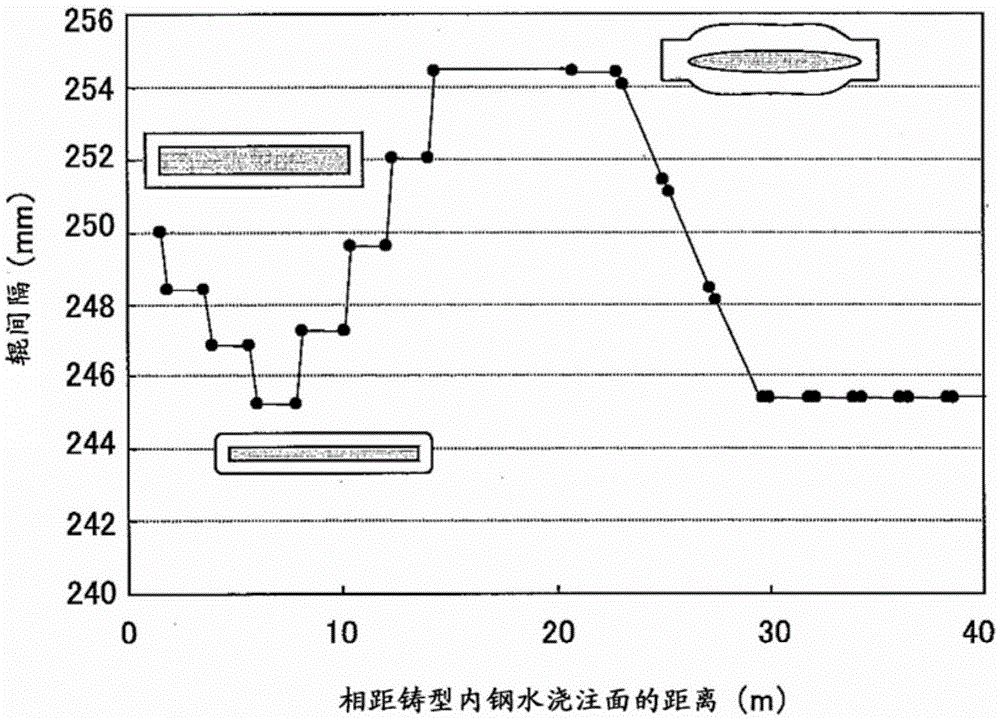

[0096] use figure 1 In the shown continuous slab caster, a test was carried out using the first embodiment of the present invention in which the cast slab was intentionally expanded and then pressed down. The width of the cast sheet is 2100mm, and the thickness of the cast sheet before the expansion starts (D 0) is 250mm. In addition, the casting speed is 0.85m / min to 1.2m / min, and the specific water quantity for secondary cooling of the cast sheet is 1.0 to 2.0 liters / steel-kg. The total amount of intentional expansion is 3.0mm to 21.0mm. The thickness of the solidified shell before expansion, the gradient of the roll opening during expansion, the casting direction length of the section where the thickness of the slab after expansion is constant (the section where the roll opening of the guide roll is set to be constant), and the pressure Experiments were carried out in various ways of changing the total amount. The cast steel grade is a steel grade for thick steel plates...

Embodiment 2

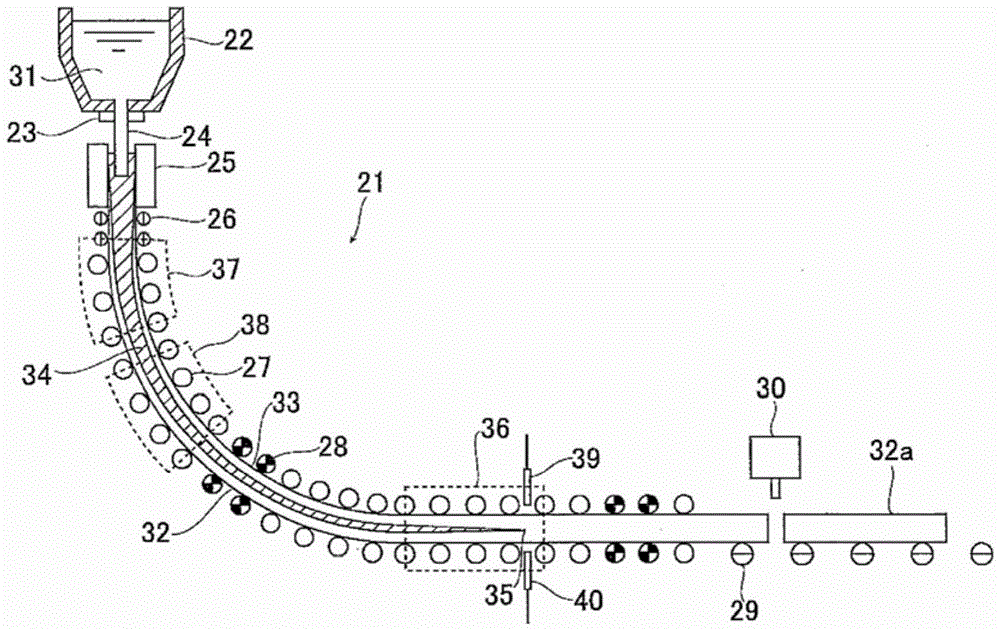

[0110] use figure 2 The slab continuous casting machine of the shown structure implemented the test which applied the 2nd embodiment of this invention and performed casting (this invention example: test number 21-25). A slab cast slab for a thick steel plate was cast with a width of 2100 mm, a thickness of 250 mm directly below the mold, and a carbon content of 0.05 to 0.08 mass %. The casting speed is 0.85-1.42m / min, and the specific water volume for secondary cooling of the casting sheet is 1-2 liters / steel-kg.

[0111] The total reduction of the short-side width narrowed reduction zone is 3.0 mm to 20.0 mm, and the total expansion of the intentional expansion zone is 3.0 mm to 20.0 mm. In addition, the total reduction of the light reduction zone is the same as the total expansion or below. In addition, the solid fraction at the central portion of the slab thickness at the end of the light reduction is 0.9 or more.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com